The aesthetic and mechanical properties of a paint coating are affected by the pigment particle size. Particle size can affect color, opacity, gloss, tinting strength, viscosity and sedimentation rate. For example, the particle size of titanium dioxide pigments is often controlled to between 0.2 and 0.35μm (or half the wavelength of light) in order to maximize its scattering and therefore it's hiding power.

Primary pigments such as titanium dioxide are the most expensive components in paints. So it is in the interest of the manufacturer to reduce the volume of primary pigment in the paint. However, this must be done without affecting the quality of the finished coating.

Powdered materials, insoluble in the application medium, were initially used as a cheap way to bulk out paint products. The cost of these fillers is around $0.1 to $0.4 where as inorganic pigments are 5 to 10 times more expensive and organic pigments are 50 to 100 times more expensive. Using fillers has allowed manufacturers to reduce the amount of some pigments from 18% to 10%, and further significant reductions have been suggested [1].

|

As the technology has moved on, it has been found that using a filler of a particular size, material or shape can improve the aesthetic or mechanical properties of the coating. These additives are now also known as extender pigments due to this change in their usage.

A wide range of materials are now used as extender pigments. For example; Chlorite is used to improve barrier properties such as water resistance because of its plate like shape. Mica, another platy material, can aid corrosion resistance. Silica is used to improve the rheology of the paint, and to flatten the appearance of the paint. Wollasonite is used to enhance film strength due to its acicular shape [2].

The material which will be covered by this application note is Barium Sulphate or Barytes. Barytes is used as an extender to control the gloss of a coating, and because it is chemically inert.

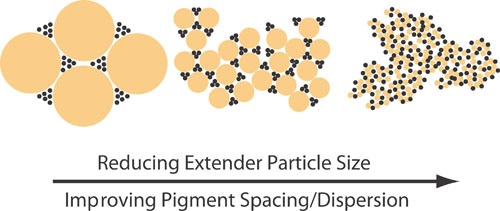

The particle size of the extender pigment can affect the coating in one of two ways. First, the extender can affect the gloss of the coating - a smaller particle size produces a smoother coating and increases the gloss. In order to achieve a high gloss the particle size must be smaller than the thickness of the film and contain no oversized particles. Secondly, the particle size of the extender pigment can be used to control the spacing of the primary pigment particles within the paint film. The spacing of the primary pigment particles affects the opacity of the coating. Too much pigment or extender can cause the particles to crowd together and reduces the opacity of the coating. Crowding can be avoided by reducing the particle size of the extender pigment (figure 1) [1].

It is therefore important in the production of Barium Sulphate to control the particle size. In particular the maximum size, or the Dv97, is controlled in order to both optimize the opacity of the coating and increase the gloss.

The aim of this application note is to show how the particle size of a Barium Sulphate extender affects the gloss of the coating. In addition to the initial gloss, the effect of the particle size on the flattening (decrease in gloss) during drying is also demonstrated. This application note will also cover how laser diffraction measurements have been used to define and control the production process.

Particle size distributions of the extender pigments were obtained using laser diffraction. This is an extremely well established technique for particle sizing. The general principles and expected instrument performances are covered by an ISO standard [3]. The advantages of this technique, and specifically of the Mastersizer laser diffraction system, include a wide dynamic range (10nm to 3.5mm), and the flexibility to measure a wide range of samples including dry powders, suspensions and emulsions. The measurements are also fast, which allows many measurements to be made in a day.

Laser diffraction instruments operate by measuring the light scattered by a group of particles over a range of angles. The angle at which a particle scatters light is dependent on its size. The particle size distribution can then be calculated using a scattering model and the optical properties of the sample.

Manufacturers of extender pigments require the flexibility of laser diffraction to measure a wide range of samples over a wide size range. The technique provides the ability to measure both wet and dry samples, as well as covering the size range from the mill feed to the final product. The instrument can be used to give immediate feedback for process tracking, allowing the size of the extender pigments to be tailored to specific applications. Alternatively, it can be used, with the aid of standard operating procedures, by quality control to ensure the specification of the final product.

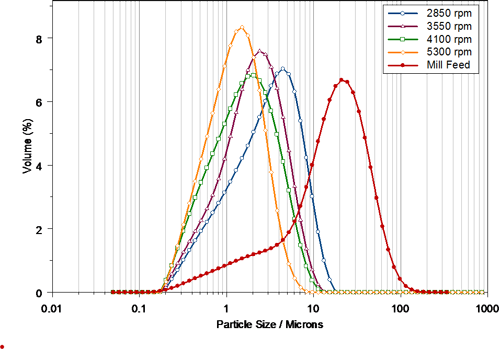

Barium sulphate extenders are produced from high purity, low silica and high whiteness natural barium sulfate. Rocks and powder are initially crushed into large lumps of around 25mm in size. A roller mill is then used to grind the material to around 45 to 50μm which becomes the feedstock for the air jet mill. In this case, laser diffraction was used to measure the size distribution of the feedstock, the result of which is used to set the initial parameters for the air jet milling process. Regular samples are then taken from the mill in order to determine when the target Dv97 value was obtained (4.5μm or lower).

Samples of different particle size were obtained by running the air jet mill at different speeds. The samples were measured using a dry dispersion unit. The Barium Sulphate samples of different particle size were then incorporated into decorative alkyd gloss paint formulations in order to establish the effect of extender particle size on the gloss of the paint coating.

The level of gloss of a coating is established by measuring the intensity of light which is reflected by the surface. A light source is used to illuminate the surface and the intensity of the reflection is measured by detectors over a limited range of angles, 20°, 65° and 80°. The gloss of the coating will then be specified at one of these angles depending on the type of paint. Measurements of gloss are relative to a polished black glass which has a gloss value of 100 at each geometry. In order to obtain reproducible measurements of gloss it is important to ensure that the surfaces are flat, of similar color and non-luminescent.

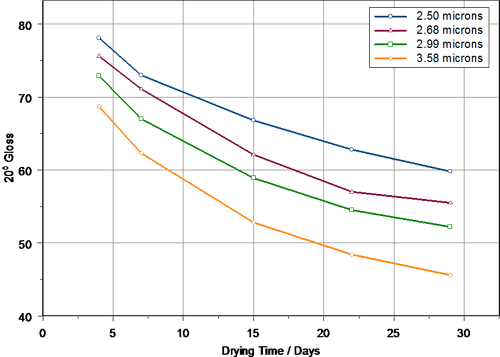

The 20° gloss of the alkyd gloss paint was measured over 25 days drying time. The paint system contained a total pigment volume concentration of 21.5%, of which the primary pigment concentration was 2.5%.

The particle size distributions of the samples obtained by running the air jet mill at different speeds are shown in Figure 2. As expected, this shows that as the speed of the mill/classifier is increased then the particle size decreases. In order to make sure that there are not oversized particles, the mill is controlled on the Dv97 (which must at least be below 4.5μm). As the size is critical to the performance of the product, measurements of particle size are taken at regular intervals during the production process to ensure that the correct size is obtained.

|

The 20° gloss was measured for the four paints made up using the extender pigments of different particle size [Table 1]. Figure 3 shows the gloss as a function drying time for the four samples. The level of gloss is higher for the sample with the smallest particle size. This corresponds to smaller particles allowing the paint to achieve a smoother coating and increasing the amount of light that is reflected. Figure 3 also shows how the gloss varies over time as the coating dries. In each case as the coating dries the gloss decreases.

| Mill Speed (rpm) | Dv97 (μm) |

|---|---|

| 2850 | 3.58 |

| 3550 | 2.99 |

| 4100 | 2.68 |

| 5300 | 2.5 |

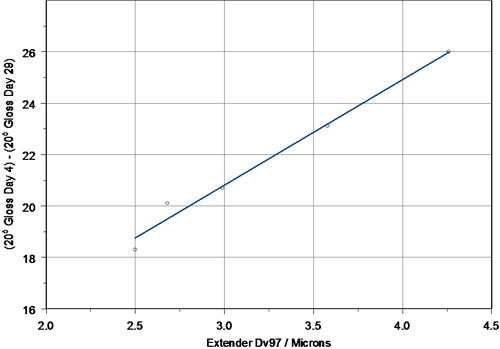

It is in the interests of the manufacturer to retain as much gloss as possible. It is therefore important to look at the difference between the 20° gloss measured on day 4 and on day 29. The difference in gloss as a function of particle size of the extender is shown in Figure 4. Again it can be seen that using an extender with smaller particle size improves the aesthetic of the coating by retaining a higher level of gloss over time.

|

|

The fact that more gloss is retained by the paint with the smaller extender particle size is again due to surface roughness. More specifically, it depends on how the surface roughness changes as the paint dries. When the paint is wet the coating for each of the samples will have a very smooth surface and consequently a higher gloss. As the coating dries the surface roughness will become increasingly dependent on the particle size of the extender. Therefore, in the coatings with the larger particle size, the surface roughness will increase and the paint will loose more gloss as it dries.

The particle size of the extender pigment Barium Sulphate has been successfully measured using laser diffraction. The results of these measurements can be used to control the production process, by enabling the correct mill speed to be set. The particle size of an extender pigment is classified on the Dv97. Controlling the Dv97 allows the proportion of oversized particles within the powder to be minimized, as these would otherwise affect the opacity and gloss of the coating.

The gloss of a coating can be increased by reducing the particle size. A smaller particle size produces a smoother coating which allows more light to be reflected and increases the gloss. Reducing the particle size also aids in the retention of gloss over time as the coating dries.

Many thanks to Howard Beedle at Viaton Industries, UK for providing the data presented in the application note.