Frequent and accurate monitoring of mineralogy, elemental composition, particle size and shape are essential to make the extraction and separation of base metals such as copper, nickel, zinc or lead profitable. Decreasing ore grades and heterogenous ore bodies require permanent information about the composition to predict and optimize recovery rates.

Malvern Panalytical solutions enable exploration, monitoring in the field, on conveyor belts, in laboratories as well as completely automated environments. Our worldwide expertise to analyze solids, powders, liquids, liquors and slurries allow fast counteractions to respond adequately on changing conditions during flotation, leaching or refining processes.

We deliver tailored analytical solutions for exploration geologists, mine planners, process engineers, quality- and laboratory managers as well as for geometallurgists and plant managers.

Mining Exploration

For both greenfield as well as brownfield exploration of new base metals deposits, portable mineralogical and elemental analysers enable exploration geologists to safely obtain immediate information in the field or mine, to define geological boundaries in real-time. With a simple push of a button, our solutions deliver mineralogy results in a matter of seconds, a rapid method to identify minerals and decrease associated exploration costs.

In addition, our NIR spectrometers can track geochemical conditions using the Al-OH scalar or the Illite Spectral Maturity (ISM) scalar an indicator of thermal maturity of a deposit. Rock chip and core analysis directly on the drilling rig allows on-the-spot decisions for optimal grade block definition, mine planning and efficient use of your drilling budget.

Epsilon 1 Mining

Grade control & ore sorting

Mineral processing of base metal ores (Cu, Ni, Zn, Pb) requires a constant quality of ore feed to the concentrator. Real-time process control provides benefits at different steps of pyrometallurgical and hydrometallurgical processes. It brings value by bulk measurements on ore passing on a conveyor belt, measuring metal grade early in the process and eventually sorting and blending low spec material from the ore stream. If a mine can effectively exclude low quality ore feed, it can effectively increase the capacity of the concentrator, regardless the process.

For hydrometallurgical processing (leach-solvent extraction-electrowinning process, SX/EW Process) on-line monitoring provide benefits at different steps of the leaching process:

- Monitoring some ore key components driving acid addition

- Optimize the quantity and cost of sulfuric acid consumption.

During the pyrometallurgical extraction of nickel from lateritic deposits (saprolites) real-time monitoring increases efficiency and metal recovery by:

- Measuring quality and moisture of the nickel ore in the mine before shipment and treatment

- Monitoring ore quality when it arrives in the treatment plant

- Optimizing the homogenization stockpile building

- Minimize energy consumption during drying and calcination to remove all the free moisture

- Control the nickel grade, the Fe/Ni ratio and the basicity index MgO/SiO2 of the material entering in the kiln

In many cases elemental information can only quantify part of the problem. Therefore, we also offer solution based on Neutron (PFTNA) and NIR technology to provide both elemental and mineralogical information directly on the conveyor belt.

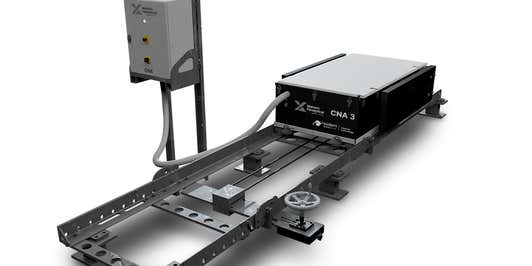

CNA³ elemental cross-belt analyzer

Separation & Refining

Reducing the cost of base metal extraction and energy consumption, milling ores to the correct grade size and frequent monitoring of the mineralogical and elemental composition are areas where we partner with base metal mining companies during ore processing. Tailored to the specific need of pyrometallurgical / hydrometallurgical processing or in-situ recovery of ores, we offer real-time monitoring, laboratory equipement as well as complete tailored automation solutions.

Together with our customers we develop predictive models to ansure fast counteractions to enable constant and optimal processing conditions.

Geometallurgy became more and more important during the separation of ore and waste material to cope with changes in raw material composition and to run the process under optimal conditions. Therefore, mineralogical analysis and the direct monitoring of process parameters (such as the acid consumption) became an essential method to monitor process conditions.

Aeris Minerals edition

Seperation by flotation

Separation of base metal sulphides by flotation depends on mineralogy, optimal particle size after milling, surface properties (zeta potential) and complexity of the ore. Our solutions for on-line particle size monitoring, mineralogical tracking using NIR and XRD as well as real-time monitoring of reagent consumption and slurry composition help to avoid poor mineral separation and low recovery rates.

Our complete solutions for elemental monitoring including accurate and fast sample preparation using high-tech automated fusion equipment ensure that impurity levels of concentrates fulfil product specifications and quality standards to avoid penalties or reprocessing.

Zetasizer range

The Minerals edition of Zetium

Solvent extraction

Whether ores or leach solutions both require on-line analysis to predict acid consumption and optimize use of energy. Real-time analysis of clay minerals enables the prediction of acid consumption during the leaching process.

Solvent extraction and electrowinning (SX/EW) address special needs for analytical monitoring. Since power consumption is the main cost factor of the electrolysis plant, permanent control of base metal concentrations in the leach and base metal solutions is mandatory to ensure optimal base metal concentration in the electrolytic bath to avoid recirculation or waste of energy.

Our on-line X-ray fluorescence solutions are manufactured for rough industrial environments such as copper, zinc or nickel refineries and have a payback time of less than 1 year.

Waste management

Reusing, recycling and recovering of mine rejects is an important factor for operating base metal mining operations in a sustainable way and to protect the environment against harmful elements. Our dedicated analytical solutions for secure safe waste management are according to international norms and regulations and avoid penalties by:

- Elemental analysis of soil and waste water

- Characterization of swelling and non-swelling clays

- Particle size and shape characterization of tailings

- Measurement of zeta potential of mine waste water and other rejects