Industrial minerals bring value to many industries and are used in a wide range of applications. These materials are of great economic value as main raw material for construction, glass, abrasives, paper, chemicals, ceramics, metallurgical and agricultural industries.

Malvern Panalytical offers a wide range of analytical solutions to enable fast and accurate exploration, monitor mining as well as processing and environmental impact. Frequent and accurate monitoring of mineralogy, elemental composition, particle size and shape are essential to make the extraction and separation of industrial minerals profitable and to meet the requirements in remote and rough environments.

A team of technical and application experts help to tailor analytical solutions to the requirements of each individual application, whether you need a portable instrument in the field, a transportable benchtop solution for a container laboratory or direct analysis on the conveyor belt.

Lithium mining & processing solutions

Lithium is produced from two types of deposits: lithium-rich brines (dissolved lithium chloride), called salars, or hard-rock granite pegmatite deposits (lithium minerals, spodumene, petalite and lepidolite).

Monitoring of crushing, grinding, concentration, thermal treatment (hard rock deposist) or evaporation and production of lithium carbonate (brines) increases the efficiency of the separation and concentration process, as extraction is chemical intensive, extremely slow, and delivers large volumes of waste.

Malvern Panalytical offers portable near-infrared (NIR) solutions for geologists for rapid and non-destructive analysis of minerals in the field to ensure fast feedback for mine planning and the definition of new lithium deposits. Our Laser Diffraction solutions enable constant control of particle size distribution of wet and dry dispersions in every step of lithium production.

Industrial X-ray diffractometers (XRD) are the preferred tool to monitor mineral composition of lithium ore, concentrates and products before and after heat treatment (α,β-spodumene) as well for the analysis of the different evaporation phases during the treatment of brines.

Mastersizer range

Uranium mining & processing solutions

Empirical Models for Canadian Unconformity-Associated Uranium Deposits

Exploration of new mine sites and potential uranium deposits has grown in the past years. Because of that, portable, rapid and non-destructive analysis of minerals in the field has become a critical piece for geologists. One of the Uranium exploration keys is identification of alteration minerals like clays (kaolinite, illite, dickite, chlorite) along the mineralized zone. Malvern Panalytical provides fast and practical solutions to determine mineralogy (based on NIR) and mineral composition (based on XRF) directly in the field, allowing more effectively refine high priority exploration targets for new uranium deposits.

For more detailed analysis in laboratories, X-ray diffraction (XRD) is an essential method to analyze mineralogy and predict processibility of uranium ores. Superior flexibility, analytical performance and stability in demanding high sample througthput mining environments are key features of our X-ray fluorescence solutions to quantify the elemental composition.

In-situ leaching (ISL) of uranium recovers the metal from the ore by dissolving and pumping the pregnant solution to the surface where the metals are recovered. Real-time elemental analysis enables operators to control and steer acid consumption and to ensure a constant uranium in-flux for further solvent extraction (SX) under minimal energy costs. Sustainable mining also requires constant monitoring of wastewater stream. On-line monitoring, especially in remote locations, enables frequent and autonomous analysis according to international norms and regulations to avoids penalties.

ASD TerraSpec range

The Minerals edition of Zetium

Phosphates mining & processing solutions

Zetium - Analysis of phosphates using the WROXI widerange oxides application

Phosphates occur as massive sediment-hosted phosphate rock or as apatite minerals in igneous and metamorphic rocks. They are normally processed through phosphoric acid and super phosphoric acid intermediates to make ammoniumphosphate fertilizers and elemental phosphorous. The presence of Fe2O3, Al2O3 and SiO2 need to be monitored because these affect the conversion of phosphates to super phosphoric acid.

Our laboratory solutions help to ensure optimal recovery rates and improved quality of apatite concentrates. Especially in mines with inhomogeneous ore quality it is important to frequently monitor elemental and phosphate composition. In this way inefficient mining of less useful rock can be avoided. Additionally, phosphate producers want to precisely control their beneficiation process of apatite to increase the recovery rate and enhance their product quality.

This can be realized by frequent analyses of the concentrates and tailings, delivering fast results. The methods of choice are X-ray diffraction (XRD) and X-ray fluorescence (XRF), which can be automated and deliver quantitative elemental and qualitative mineralogical data in a relatively short time.

Epsilon 4 Mining & minerals

Heavy Mineral Sands analysis

Analysis of heavy mineral sands for industrial process control

Heavy mineral sands are a class of ore deposits that are an important source of titanium, zirconium, thorium and rare earth elements. Often X-ray fluorescence (XRF) or wet chemistry are used to obtain elemental information for metallurgists to estimate the mineral processing performance. Since the efficiency of concentration and reduction depends on the content of the different titanium and iron phases, such as ilmenite FeTiO3, magnetite Fe3O4, hematite Fe2O3, rutileTiO2, anatase TiO2 zircon ZrSiO4, and monazite (Ce, REE)PO4 as well as the various titanium oxides with different oxidation stages, a fast and direct analysis of the phases is required. X-ray diffraction (XRD) can be used to readily identify the mineral phases present in heavy mineral sands.

During the last decade XRD became a standard tool in the mineral industries due to the diverse applications and the improvements in speed, accuracy and flexibility of the analysis. Pigments are only one the multiple products made from TiO2. Since the size of titanium pigment particles affect the opacity, colour, gloss, viscosity and sedimentation rate of a suspension, the particle size distribution (PSD) is the most important factor for titanium dioxide. Laser Diffraction is a widely used technique for the analysis of titanium dioxides due to its wide dynamic range, sub-micron performance and flexible options for both wet and dry sample dispersion.

Mastersizer range

The Minerals edition of Zetium

Rare Earth Elements (REE) mining solutions

During the past twenty years, there has been a huge demand increase for many items that require rare earth metals. Rare earth exploration and mining of new REE deposits require more accurate and more frequent monitoring during mine planning and ore beneficiation. Malvern Panalytical offers solutions to.

- Help geologists to identify geological domains of new potential REE deposits directly in the field

- Enable REE monitoring on conveyor belts to optimize bending of different ore grades

- Monitor elemental composition and REE bearing minerals such as bastnäsite, synchesite, monazite, xenotime, florencite, eudialyte, catapleiite, aeschynite or samarskite

The knowledge of the mineralogical and elemental compositions is the key for efficient characterization of the ore grade and defines the behaviour of the ore during the different processing steps. Frequent monitoring of the mineralogy saves costs for reagents and leads to an efficient concentration of the ore minerals from the raw ore feed.

ASD TerraSpec range

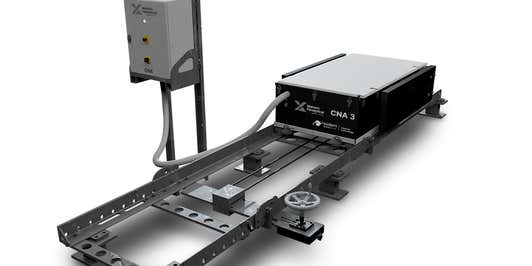

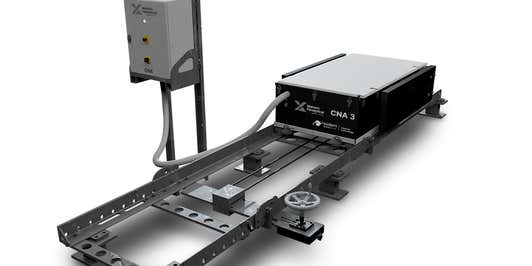

CNA³ elemental cross-belt analyzer

The Minerals edition of Zetium

Potash Fertilizer Analysis

Potassium, a common soil fertilizer, is important for modern agriculture as it improves water retention, nutrient value, and disease resistance of food crops. Often referred to as potash, most industrial potassium is derived from sylvite deposits. Potash ores are typically rich in sylvite (KCl) and halite (NaCl). Carnallite (KCl MgCl2 6H2O), a key potass ium-bearing mineral used for potassium production, is usually spatially associated with halite. The occurrence of halite may reduce the economic benefit of sylvite and increase difficulties during potassium purification. Therefore, to improve processing efficiency, it is necessary to determine halite content and distinguish carnallite from gangue minerals. The dissolution for separating carnallite from halite is time-consuming and costly.

We offer solutions for potash exploration with remote sensing or in the field as well as analytical solutions in the laboratory to predict the efficiency of the mineral separation. This enables fast feedback loops during mining and separation of potash ore and ensures potash companies are competitive and manufacture efficient.

The Minerals edition of Zetium

Limestone Production Solutions

Analysis of limestone prepared as pressed powder pellets

Limestone is the principal source of CaCO3, which is used as raw material in a wide range of applications. It is used as an additive in steel making, as main component for cement and, when purified, it even can be used as supplement for calcium-rich animal feed or pharmaceutical fillers. The grade and application of the limestone is determined by the ratio between the main compounds, as well as the presence of other minor and trace compounds, like MnO, P2O5 and Pb.

Although limestone is excavated and used for thousands of years, current environmental legislations demand miners to continue excavating parts of existing quarries, with so-called fringe material. Since the composition in such parts is more inconsistent, frequent and accurate grade monitoring is mandatory. Malvern Panalytical’s transportable X-ray fluorescence spectrometers (XRF), can be put in the back of the car and can analyze limestone directly in the quarry, making it easier to determine the best place to excavate. Once on a conveyor belt, quality and the grade of limestone can be continuously monitored using an on-line elemental analyzer based on safe neutron technology. In combination with real-time near-infrared (NIR) mineralogical monitoring, information about the process parameters, elemental and mineral content including clays, ensure optimal sorting and blending.

CNA³ elemental cross-belt analyzer