While much effort is expended in optimizing commercially operating plant, getting the process 'right first time' can be far more efficient. Real-time analysis of process parameters provides substantial support during development, streamlining and accelerating the evolution of successful process designs.

Taking on-line particle size analysis as an example, this paper considers the rationale for investing in real-time measurement for pilot scale work. Case studies illustrate the various ways in which on-line systems promote efficient process development, easing the transition into profitable manufacture.

While much effort is expended in optimizing commercially operating plant, getting the process 'right first time' can be far more efficient. Real-time analysis of process parameters provides substantial support during development, streamlining and accelerating the evolution of successful process designs. This paper presents the case for investing in real-time process measurement for pilot studies.

Real-time process analysis systems are used increasingly within the manufacturing environment. Automating analysis, and indeed control, dramatically reduces operational variability and its associated inefficiencies - as advocated by six sigma. Automation can pay big dividends by improving product quality and at the same cutting the cost of production. These savings quickly offset installation costs, strengthening the economic argument in favour of investment.

The financial case for automation at the pilot scale may be less easy to make. Here, potential benefits are not so immediately obvious, and can be harder to quantify, but are nonetheless considerable. The scope for more consistent operation, and the efficient correlation of 'cause and effect', accelerates and improves product and process development alike, bringing faster and more efficient commercialization. This drives down R&D spend, an important goal in many sectors.

Taking on-line particle size analysis as an example, this paper considers the rationale for investing in real-time measurement for pilot scale work. Case studies illustrate the various ways in which on-line systems promote efficient process development, easing the transition into profitable manufacture.

As a product moves through early stage research towards commercialization, the impetus is to develop a robust process that will secure consistent, profitable production over the long term. Pilot scale trials often have an important role to play. Operating small scale units, which replicate part or all of a proposed or existing full-scale plant, is a relatively inexpensive way to experiment towards the best processing solution. The term 'relatively inexpensive' is, however, used advisedly here, since pilot scale trials are often associated with significant expenditure. Furthermore they are an upfront investment, cash spent now in anticipation of future, rather than immediate reward. Maximizing efficiency is essential.

In considering the contribution that real-time analysis can make, it is worth examining possible goals of a pilot scale study. These might include:

Reaching these goals in a timely way demands the rapid acquisition of understanding. The pilot scale may follow directly on from fairly basic lab work, designed to simply prove the viability of a product. Little may be known about the feasibility of different manufacturing options and it is important to learn fast.

The real-time measurement of key process or product parameters eases pilot plant control and increases experimental efficiency. Consider the example of a trial designed to establish optimal milling conditions. When milling, particle size is a defining characteristic of the product so it is useful to examine what happens when using periodic particle size measurement compared with applying real-time analysis.

Periodic, off-line analysis provides a snapshot of the process each time a sample is taken. Material is extracted from the plant, taken away for analysis, and the results returned some time later. Time lags, between extraction of the sample and the return of results, are unavoidable.

Returning to milling. A change is made to a mill parameter and there is an immediate impact on exiting particle size. Sample is extracted from the exit stream, worked up and the results obtained perhaps an hour later. Careful correlation enables assessment of the impact of the initial change. However, it may prove necessary to take multiple samples to precisely quantify the result. Furthermore, if the mill does not normally operate smoothly it may be difficult to differentiate the effect of the change from baseline steady state variability.

Continuously monitoring the particle size of the exiting material provides a number of benefits. Firstly, because the operator can properly observe how the plant is running, it can be operated with greater smoothness, establishing an improved baseline for experimentation. More consistent steady state operation also makes it easier to provide representative material for product testing. Most importantly, as soon as a change is made the results are immediately obvious. Cause and effect can be rapidly quantified in a statistically relevant way and the rate of experimentation becomes limited solely by the dynamics of the process, by how long it takes changes to filter through the plant. The unit can be moved swiftly and efficiently from one experimental condition to another, and the results of each experiment captured rapidly and completely.

This capability of real-time measurement to deliver steadier pilot plant operation, and precisely capture even the subtle effects of a process change, can accelerate and improve developmental work, and increase confidence in the resulting solution. The following studies provide very practical illustrations of the potential benefits.

Engineers at the Universidade Federal de Itajuba (UNIFEI)(Brazil) innovate practical solutions that enhance the efficiency of crude oil processing. One strand of research is the evaluation and improvement of separators for oil-in-water emulsions. Key to the success of this project is the generation of feed emulsions, representative of those encountered in oil processing. The group has a pilot scale unit that produces emulsions at a flow rate of up to 18 m3/h. Oil concentration and operating pressure are varied to tailor characteristics for any given application.

Here, consistent controlled emulsion production provides a foundation for the work. Without a stable feed it is not feasible to assess separator efficiency and progress towards better processing solutions. Steady operation of the test bed is secured via real-time particle size analysis of the material exiting the emulsification unit.

|

|

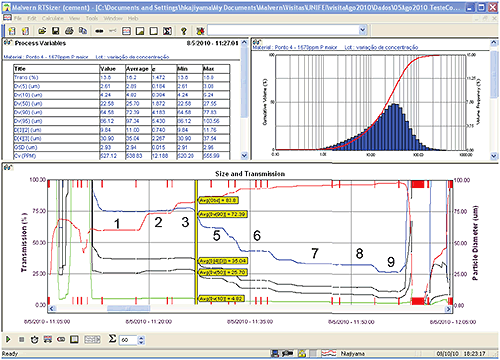

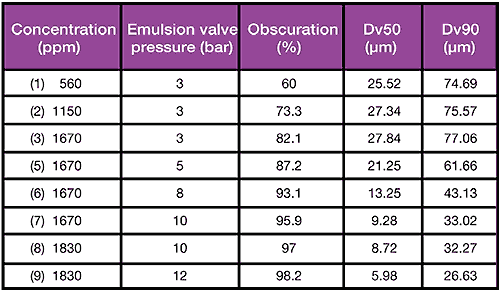

Figure 1 shows data from a trial which tests the ability of a laser diffraction on-line analyzer (Insitec, Malvern Instruments) to monitor emulsion droplet size as test bed conditions are altered. In tests 1 to 3 the concentration of oil in the system is being increased. This has a negligible impact on the volume moment mean of the particles D[4,3] and on the Dv90 (the size below which 90% of the particle population lies) but increases obscuration (red line).

Higher obscuration indicates that less of the light from the analyzer source laser is reaching the detectors, suggesting that as oil concentration is increased the process stream becomes more opaque. In tests 5 to 7 the pressure applied during emulsion production is steadily increased, driving down Dv50, and indeed the other size parameters Dv10 (the size below which 10% of the particle population lies and Dv90 ). In test 8 a further increase in oil concentration is made, pushing obscuration up to 97.5%. And in the final test (9), pressure is raised further, to 12 bar, to produce an emulsion with the very finest droplets, a Dv90 of 26.63 microns.

The time axis for the screen shot shows that all these trials were completed in just one hour. In this example then, the on-line analyzer allows the experimenter to very quickly find, set and control the conditions needed to produce a suitable emulsion. Analyzing emulsions away from the test rig could be problematic if they are at all unstable, and would certainly slow down the task of identifying optimal production conditions. Furthermore, on an ongoing basis the facility to precisely control the production test bed will greatly improve the quality of research into the efficiency of downstream separation processes.

In a detailed assessment of different mill types for the production of a new marble powder, engineers at Ferrari Granulati (Verona, Italy), a market-leading producer of marble granulates and powders, identified a vertical roller mill (VRM) as the preferred option. This choice was based on energy efficiency and equipment footprint but presented a challenge. These mills are not routinely used to produce powders of the fineness required: a Dv50 of between 3 and 8 microns coupled with a Dv98 of between 15 and 50 microns.

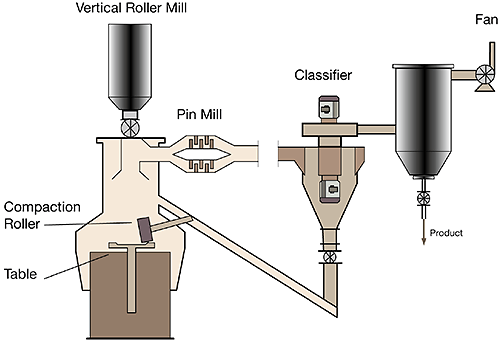

Working with mill manufacturer STM (Varese, Italy), Ferrari Granulati embarked on a project to develop a novel milling circuit based on a VRM that would deliver in-spec material. A classifier for final product separation completed the circuit.

Recognizing the importance of particle size information the project team elected to install an Insitec on-line particle size analyzer from the outset. Modifying the mill towards acceptable performance for the application would rely on detailed investigation of the factors controlling particle size and intelligent modification of the hardware. The team recognized that continuous measurement would streamline this process and this proved to the be the case. With real-time particle size analysis in place they were able to rapidly assess the benefit or otherwise of a modification and innovate efficiently towards an optimal processing solution.

The primary reason why VRMs are not used to produce powders with a Dv98 below 50 microns is that such fine materials tend to flow under the compacting rollers without being broken up. Comminution in these mills relies on effective crushing of the particles between the roller and table. A first step was therefore to develop as suitable solution to this intrinsic limitation.

|

By installing a simple mechanical transducer on the arm of the compaction roller (see figure 2), Ferrari Granulati could automatically control the depth of powder on the table, to maximize the impact of the rollers. The transducer continuously measures powder depth. If the powder layer trends below the optimum 15 mm, the rotational speed of the table automatically reduces, retaining more powder on the table and re-building depth. Generally speaking the table rotates at relatively low speeds of around 25 to 30 rpm.

A second, generic problem associated with very fine powders is their greater tendency to agglomerate. Within this particular circuit, agglomerates will be classified by the separator as over-sized and recycled to the mill for further grinding, setting up an energy consuming internal recycle.

This issue was addressed through the installation of an in-line pin mill immediately upstream of the classifier. Rotating relatively slowly for a pin mill, at about 300 - 400 rpm (the external diameter of the mill is 500 mm), this unit provides sufficient energy to break-up most agglomerates before they reach the classifier, improving energy efficiency, optimising mill throughput and avoiding excessive wear.

Finally the team had to consider how to set air flow rate through the circuit. This air flow has two roles. Within the mill it lifts fallen powder back onto the table for further milling, and it also transports material from the mill through to the classifier. With coarser materials, the air flow required for these two duties is roughly comparable, but where finer materials are involved the air flow required for pneumatic transport/classifier operation is much lower than that needed to contain material on the table.

Since an excessively high air flow through the system has negative implications for energy consumption, the chosen solution was to operate with an air flow sufficient only for classifier operation. A screw auger was therefore installed to mechanically transport material that falls from the table to the inlet of the pin mill, allowing its classification along with other milled material. Once set to give effective transport through the circuit and efficient classifier operation, volumetric air flow rate is kept constant during the production of any given product, stabilising operation.

The developed milling circuit has proven a great success, a success, that Ferrari Granulati substantially attributes to the availability of real-time data throughout the development process. Without on-line analysis the company believes it's ability to engineer solutions to meet the challenge of using VRM technology for this application would have been severely compromised. Extremely stable and very responsive, the mill produces powders of exemplary quality at competitive price with no manual intervention. Energy consumption has been minimized and waste eliminated.

The pharmaceutical industry is currently engaged in a very critical analysis of its manufacturing practices. With a legacy of relatively inefficient batch production the sector is working to transform operations, increase its use of continuous processing and move closer to the goal of real-time product release. Catalysed by the FDA's Process Analytical Technology (PAT) initiative, pharmaceutical manufacturers are actively seeking analytical techniques that will underpin the development of more efficient processing strategies.

For pharmaceuticals, milling is a common unit operation, used to process active and excipient particles to a defined size for the production of, for example, tablets or inhalable formulations. Here, the commercial availability of reliable real-time particle size measurement systems provides opportunities for automation that are less accessible for processes where relevant continuous analysis is not yet feasible. Exploiting this potential, a global pharmaceutical manufacturer has recently commercialised a generic automated milling solution with widespread applicability.

The developed solution, which uses a comminutor mill, is simple but effective. Material entering the mill via the throat is broken up by rotating blades, which simultaneously apply cutting and impacting actions. Particles within a defined size range exit via the screen while oversized material is retained for further comminution. Although blade profile and screen specification both influence the size of the exiting particles, rotor speed is the principal control variable.

Pilot scale trials with an Insitec on-line particle size analyzer provided convincing evidence that this system could efficiently and continuously monitor, in real-time, material exiting the mill. Having identified this solution, steps were taken to integrate the mill and analyzer such that the particle size data could be used to automatically control mill speed. A closed control loop was implemented to automate mill operation.

The operator interacts with the automated mill through the mill human machine interface (HMI), which runs on a dedicated PC. From here it is possible to input particle size set points for the control loop, remotely start and stop the analyzer and mill, perform background tests, and receive particle size results. Using the particle size set point, the mill PLC will adjust speed within a defined control range to maintain the particle size specification.

The loop was tuned using proportional (P) control. The chosen feedback parameter was average Dv50 with a 30 second rolling average. In tests, set point was reduced from an initial value of 58 microns down to 50 microns and then back up to the original value. The mill stabilized at the first set point after about a minute, reached the second approximately 30 seconds after the change had been made, and completed the final transition in less than 2 minutes. This performance highlights the effectiveness of the control system..

This automated solution, proven at the pilot scale and now commercialized, is applicable to any number of manually operated mills. In pharmaceutical production a widespread task is to mill a batch of material, from, for example a crystallizer, to establish a uniform particle size. Using manual control this is a potentially lengthy task that involves first setting processing conditions to hit the size specification, and then maintaining tight control in the event of variation across the batch. In contrast, the automated solution rapidly identifies suitable operating conditions, and then automatically adjusts them in response to feed variability.

In this example, pilot studies were used to prove the on-line technology and the feasibility of automation, generating the confidence necessary to commercialise an efficient processing solution. There is clearly potential for this pilot scale work to be very amply rewarded if the solution is rolled out to both pilot and manufacturing plant across the company.

In the production environment, real-time process analysis supports the manufacture of better quality product, at competitive cost. With pilot studies the output is knowledge rather than tonnes through the gate. Here, real-time analysis supports the attainment of better understanding, at competitive cost. Continuous process analysis enables more controlled pilot plant operation and enhances investigative research. The result is a faster, more confident transition to profitable manufacture.