Polyvinyl alcohol (PVOH) is a water-soluble synthetic polymer made by alcoholysis of polyvinyl acetate. Its properties depend on the degree of polymerization and the percentages of alcoholysis. To control the performance of this material, such as water solubility, strength, elongation, toughness etc., it is important to monitor the molecular weight and intrinsic viscosity of the production. The following FIPA method provides a fast, accurate and precise measurement of these molecular parameters that is user friendly and robust in a plant/process control environment.

For the front end of the chromatography system, a Viscotek GPCmax integrated degasser, pump, and autosampler was used. For detection a Triple Detection Array (TDA) system was utilised. The detectors in series were the light scattering (LS), the differential refractometer (RI) and the viscometer (differential pressure, DP). The eluent used was 0.1M NaNO3 at a flow rate of 1.0 mL/min. The separation of the polymer and the solvent was carried out using a ViscoGEL column FIPA-100W. The samples were made up at 4 mg/mL and a volume of 100 µL was injected. The TDA's isothermal chamber housing the three detectors and the FIPA column was kept at 30 °C.

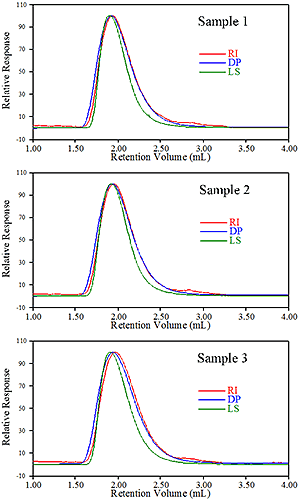

Figure 1 presents the FIPA chromatograms (FIPAGrams) of the three samples. The FIPA-100W (100 Angstrom) column is providing a very nice polymer peak in about 3 minutes, but, there is little or no resolution of the polymer distribution. The FIPA calculation method provides only the MW and IVW averages.

|

Sample ID | Mw (Da) | SD (Da) | IVW (dL/g) | SD (dL/g) |

|---|---|---|---|---|

Sample 1 | 127,200 | 500 | 0.966 | 0.003 |

Sample 2 | 107,900 | 400 | 0.940 | 0.001 |

Sample 3 | 65,500 | 300 | 0.674 | 0.003 |

Table 1 presents the FIPA results for the three PVOH samples. It is clear that the repeatability of these FIPA runs (4 injections for each sample) is excellent for both MW and IVW values. It should be noted that there are basically no noticeable difference between the three FIPAgrams despite the fairly significant MW and IV range of the three samples. With FIPA, the polymer is simply separated from the solvent it was dissolved in and from other contaminants like salts and other small molecules.

The parameters (MW and IVW) are measured in the eluent directly by the detectors. The elution time is not needed for the molecular weight and IV calculations. The RI detector is used for the global concentration of the sample. The light scattering detector is used in conjunction with the RI detector to obtain the weight average molecular weight. The viscometer has two signals, the inlet pressure (IP) and the differential pressure (DP). Both are used with the concentration to obtain the intrinsic viscosity of the polymer sample.

In conclusion, FIPA is a fast, precise and accurate analytical tool for routine process and quality control. This technique provides quick and easy simultaneous measurements of MW and IVW. This FIPA technology can be particularly important for a premium product because of performance and uniformity requirements. Furthermore, quick process feedback can help reduce production of off-specification material and improve plant capacity.