The preferred orientation of crystallites constituting polycrystalline solid materials such as metals, ceramics or composites significantly influences the intrinsic properties of the respective solid. In material sciences this preferred orientation is commonly known as texture and describes the orientation of all crystallites in a sample with respect to a reference frame defined by the sample orientation.

Using X-ray diffraction (XRD) the texture of a sample is usually measured using the approach developed by Schulz (1949) where the intensity of certain (hkl) reflections is measured as a function of the sample orientation. This is conventionally done by rotating (ϕ) and tilting the sample in axial plane (𝜒). Hence, point focus optics as well as an Eulerian cradle are required.

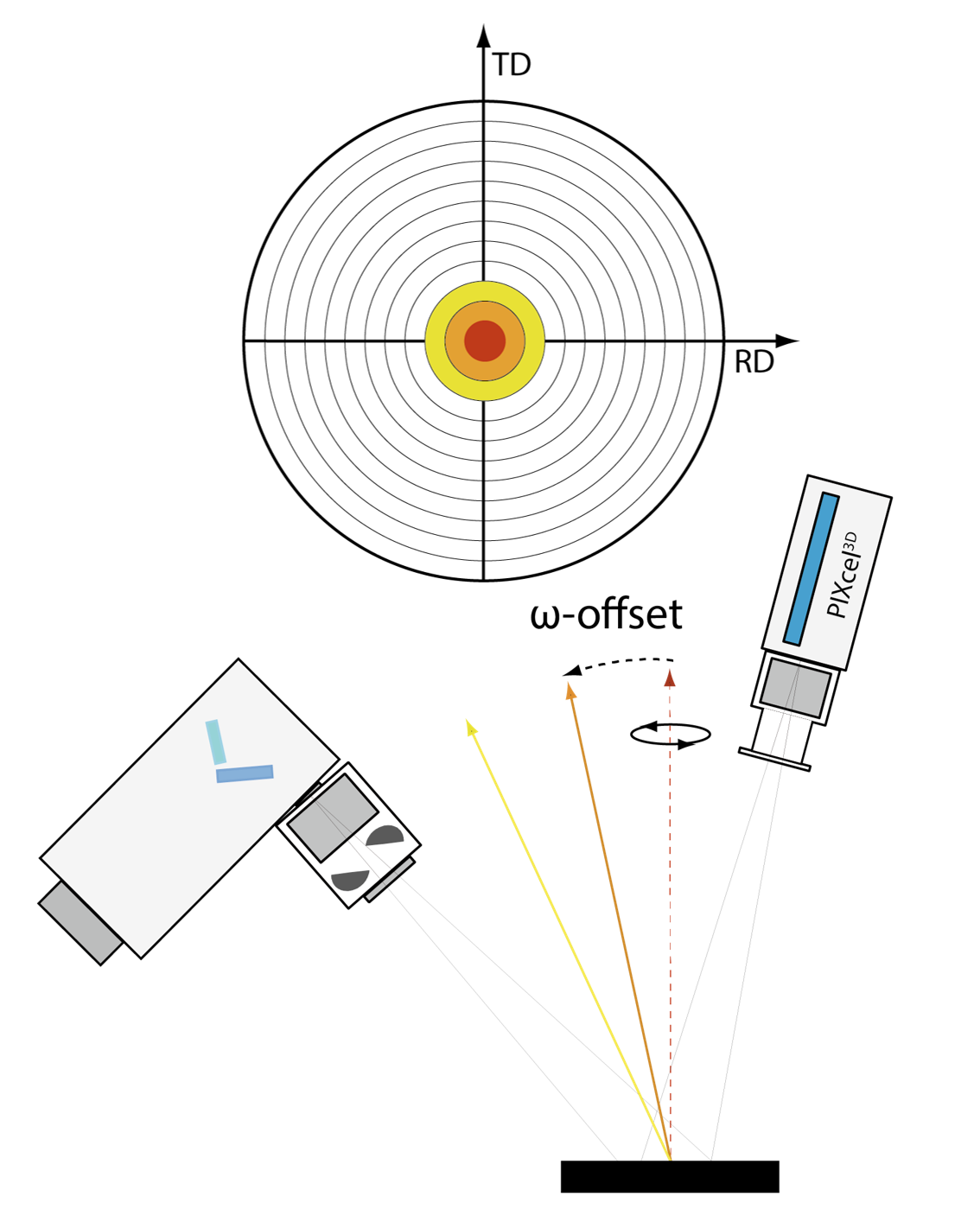

In contrast to the conventional Schulz-technique, in the ω-texture approach different sample tilts in the equatorial plane are accessed by applying a ω-offsett to the goniometer while keeping the sample horizontal and rotating it in ϕ (Fig. 1). Therefore ω-texture allows measurements of complete pole figures in line focus without the need for an Eulerian cradle and point focus optics.

The preferred orientation of crystallites constituting polycrystalline solid materials such as metals, ceramics or composites significantly influences the intrinsic properties of the respective solid. In material science this preferred orientation is commonly known as texture and describes the orientation of all crystallites in a sample with respect to a reference frame defined by the sample orientation.

Using X-ray diffraction (XRD) the texture of a sample is usually measured using the approach developed by Schulz (1949) where the intensity of certain (hkl) reflections is measured as a function of the sample orientation. This is conventionally done by rotating (ϕ) and tilting the sample in axial plane (𝜒). Hence, point focus optics as well as an Eulerian cradle are required.

In contrast to the conventional Schulz-technique, in the ω-texture approach different sample tilts in the equatorial plane are accessed by applying a ω-offsett to the goniometer while keeping the sample horizontal and rotating it in ϕ (Fig. 1). Therefore ω-texture allows measurements of complete pole figures in line focus without the need for an Eulerian cradle and point focus optics.

This new technique offers new possibilities for implementing advanced texture analysis as a routine analysis in combination with powder diffraction, thin film/high resolution and residual stress analysis without the necessity to change the tube focus, optical components or the sample stage.

Figure 1: S chematic demonstrating the principle of a pole figure measurement with the ω -texture approach on a θ-θ goniometer. The goniometer is tilted in the equatorial plane ( ω -offset) while the sample remains horizontal. This results in different sample orientations each represented by a pair of ω-offset and ϕ-values. The accessible sample-tilt range is defined by the 2θ position of the respective reflection. Higher diffraction angles result in a larger accessible sample-tilt range and hence in a larger coverage of a pole figure.

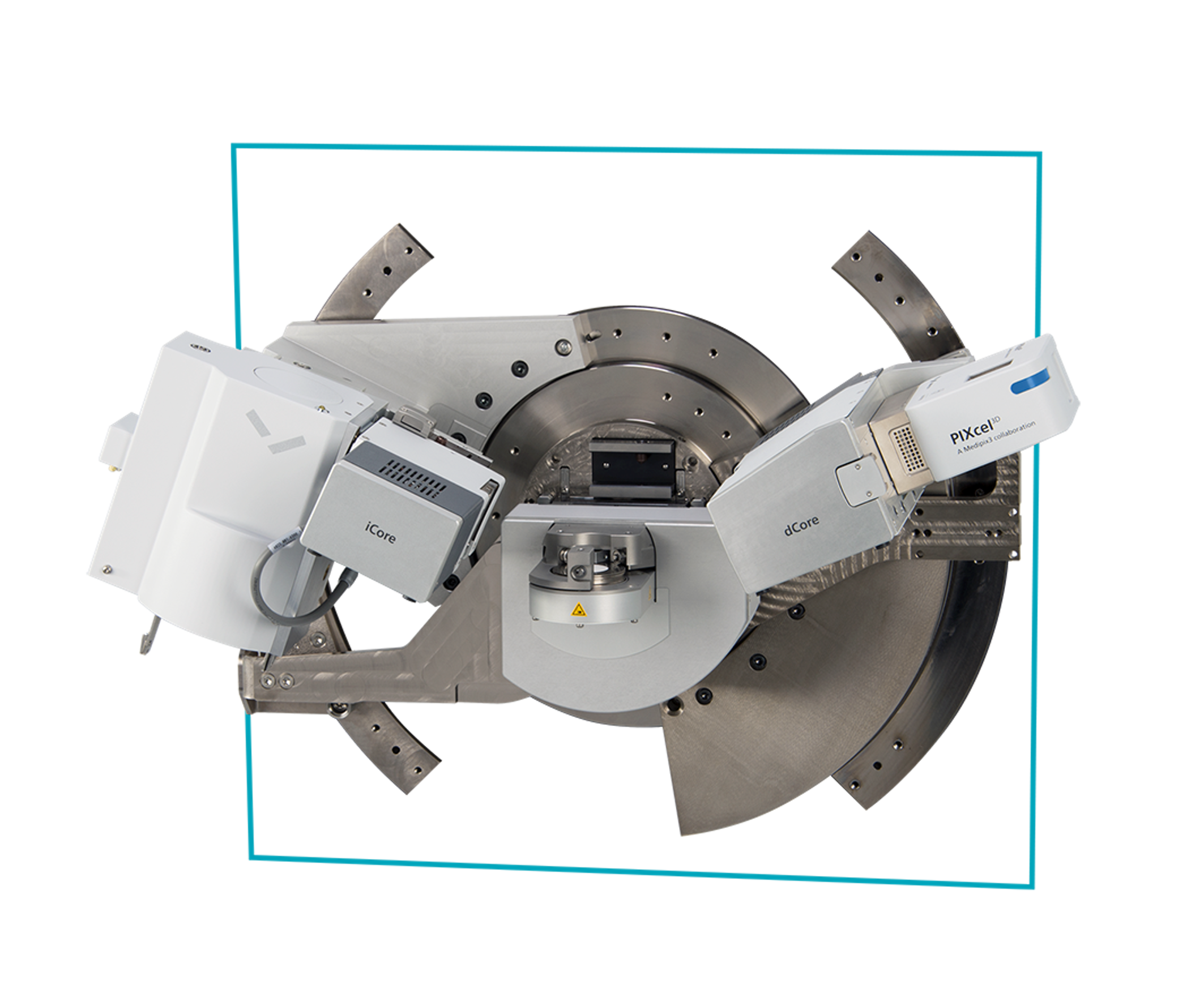

The measurements were performed using an Empyrean multi-purpose diffraction platform equipped with Cu- or Co-radiation in combination with the new multicore optics line-focus setup, a reflection-transmission spinner-stage, and a 45-position sample changer as used for the conventional powder XRD measurements. On the incident beam side the iCore-Cu or iCore-Co module was used, the diffracted beam side was equipped with the dCore and a PIXcel3D detector.

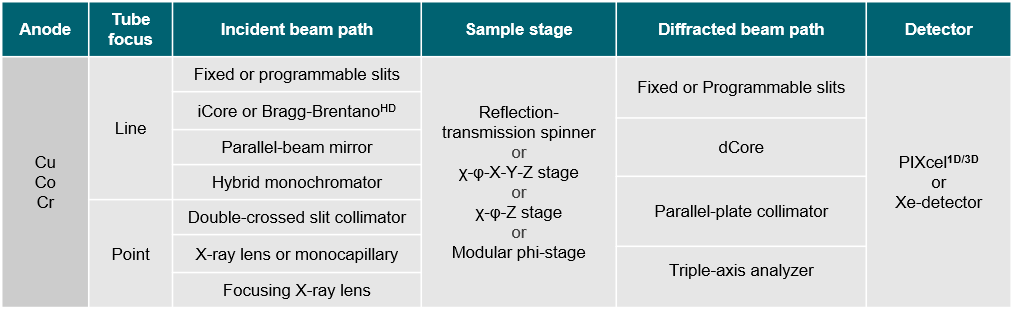

ω-texture can be measured with a wide range of different setups depending on the sample requirements (size, weight, spot size) as can be seen in table 1.

Table 1: Possible instrument setups for ω-texture measurements showing that this technique can be easily combined with powder XRD, phase analysis, residual stress, GI-XRD (grazing incidence diffraction), micro-diffraction and even high-resolution diffraction on epitaxial layers

F igure 2: Measurement setup used in this study

For this study three samples were selected: (i) a Zircaloy sheet as commonly used in nuclear fuel tubing for nuclear reactors, (ii) rolled steel, and (iii) a Ni-coating, both originating from the automotive industry.

However, the same analytical approach can equally be applied to other metals (e.g. Al, Ti, Cu, Cr, Co, Au, Pt), hard metals (e.g. TiN, TiAlN, TiC, CrN, WC), ceramics (e.g. Al2O3, ZrO2,) and other materials (e.g. PZT, GaN).

Texture analysis of these type of materials is a common procedure in process and quality control as it can predict potential sources of failure.

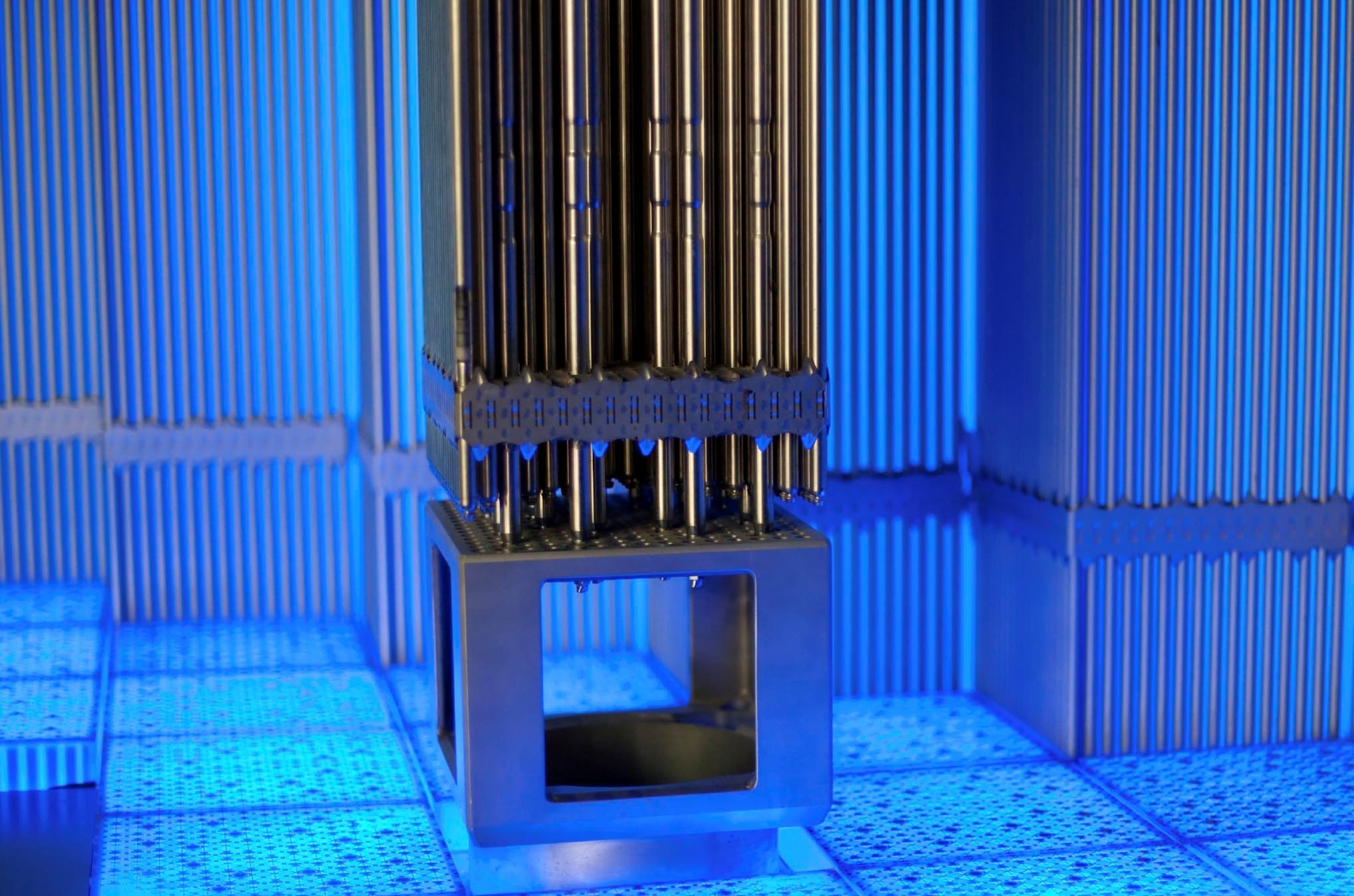

Figure 3: Nuclear fuel tubes in which Zircaloy is commonly used

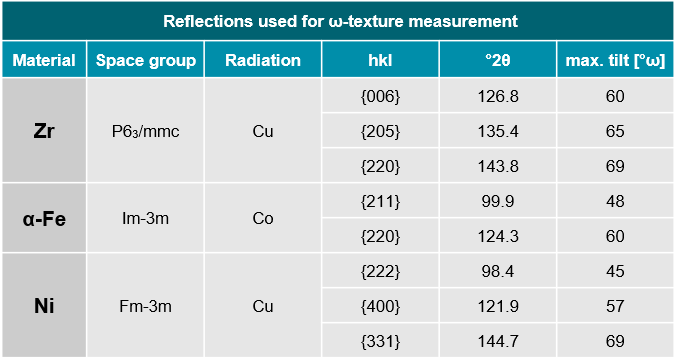

Table 2: List of reflections measured using ω-texture.

Zircaloy

Pole figures of the (006), (205), and (220) reflection of Zircaloy were measured with Cu radiation on the Empyrean using the ω-texture approach. The sample was slightly misaligned with respect to the equatorial plane of the diffractometer.

The respective pole figures of Zircaloy collected on the Empyrean shows a strong rolling texture typical for rolled hexagonal metals is observed. For these type of metals the {00l} direction is the most representative and can be used to quantify the texture and to monitor the variations in production. The measured Zircaloy (006) pole figure exhibits the characteristic, symmetric features parallel to the rolling direction associated with the rolling texture of Zircaloy.

The data also shows that despite the somewhat limited sample tilt range compared to the classical χ-tilt texture method, the respective pole figure measurements contain sufficient, relevant information to characterize the texture of Zircaloy in the various directions.

Ferritic steel has four accessible reflections when measured with Co radiation of which two are suited for ω-texture measurements as shown in figure 5. Both reflections nicely show the symmetric features characteristic for the rolling texture in body-centered cubic metals (bcc). The {hh0} is the most prominent direction in Fe-bcc. The accessible tilt-range for the (110) reflection is too restricted using the ω-texture approach but the tilt-range of the equivalent (220) peak is sufficient to access the same texture features.

Rolled steel

Pole figures of the (211) and (220) reflection of ferrite (α-iron) were measured with Co radiation on the Empyrean using the ω-texture approach.

In contrast to bulk metals, the Nickel coating shows a pronounced fiber texture typically observed in polycrystalline coatings and thin films. The spot-like feature of the (400) pole figure in Nickel coating is caused by the near perfect alignment of the {h00} lattice planes parallel to the sample surface, which represents a strong {h00} fiber texture. The other crystallographic directions consequently show isotropic, concentric rings at angular positions given by the fcc symmetry and lattice parameters of Nickel.

Nickel coating

Pole figures of the (222), (400), and (331) reflections of nickel were measured with Cu radiation on the Empyrean using the ω-texture approach.

Malvern Panalytical’s novel ω-texture approach offers a simple, fast and efficient way to obtain texture information of various sample types even with the most basic diffractometer setup. The ω-texture method can be easily combined with phase analysis, thin film and residual stress analysis, eliminating the necessity to change tube focus, optical setup or even the sample stage to an Eulerian cradle. In combination with a sample changer ω-texture can be used for continuous quality control.

Furthermore, the fact that on a θ-θ goniometer the sample remains horizontal throughout a pole figure measurements is beneficial for texture measurements on large or heavy objects.