Press and sinter

Material characterization solutions for pressing and sintering

Material characterization solutions for pressing and sintering

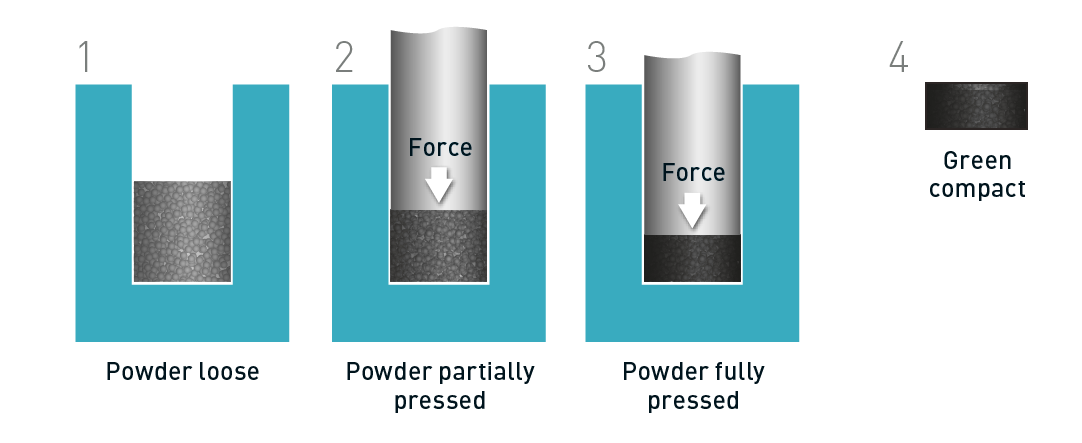

To increase the strength, conductivity, and toughness of metallic additive manufacturing materials, manufacturers often apply pressing and sintering. In fact, this is the manufacturing method most commonly associated with powder metallurgy. It involves three basic steps:

For materials like ceramics and hard metals, the primary powder is often spray-dried to form a feedstock with improved flow characteristics and compressibility.

In order to achieve consistent quality in the feedstock, ‘green body’, and final sintered component, the metal or ceramic powder’s characteristics must be carefully optimized. To support press and sinter manufacturers with this, Malvern Panalytical offers a range of powder characterization solutions.

Please download our brochure to find out more.

As with other powder metallurgy processes, powder characteristics can greatly affect the results of pressing and sintering, and should, therefore, be carefully characterized. Particle packing and the apparent density of the powder blend are particularly critical. A lower apparent density, for instance, produces greater compaction and cold-welding in the particles on pressing, resulting in a stronger ‘green body’.

Another important powder characteristic is interparticle friction, which facilitates contact, deformation, and densification of the structure during pressing. Phase composition and grain size are also important to control, since these characteristics can affect the powder’s hardness and thermal properties. This, in turn, affects not only pressing efficiency and sintering behavior but also the mechanical properties of the pressed part. Finally, the powder must also comply with the alloy composition of the material specified.

To support manufacturers in meeting these requirements, Malvern Panalytical offers several characterization solutions for press and sinter. These can be used to: