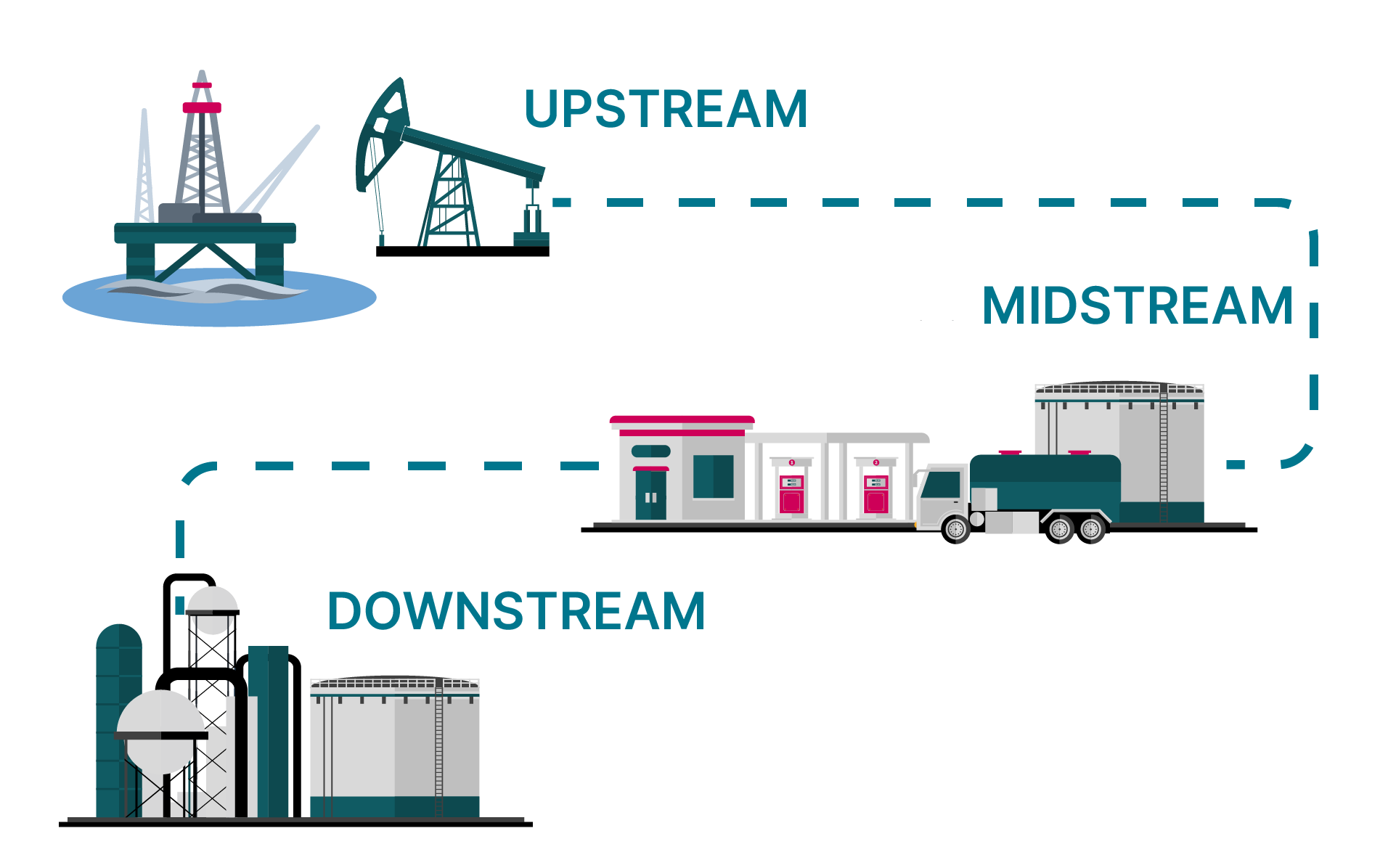

Le ayudamos a operar activos rentables, innovadores y duraderos, desde plataformas petrolíferas hasta plantas petroquímicas

En toda la industria de los aceites y petroquímicos, el impulso para mejorar el impacto ambiental está creciendo. Al mismo tiempo, dada la fluctuación de los precios del petróleo, los productores deben seguir optimizando sus procesos para lograr la máxima eficiencia y calidad a un costo mínimo.

Con retos como los productos químicos peligrosos, la corrosión, la intemperie y el cambio hacia instalaciones automatizadas y no tripuladas, puede ser difícil satisfacer todos estos requisitos. Nuestras soluciones líderes en el sector, el control de calidad, los estándares de cumplimiento y la formación hacen que esto sea más fácil. ¿Cómo? Al ayudarle a proteger combustibles y polímeros de alta calidad, identificar impurezas, reducir los residuos y optimizar sus procesos de producción.

Benefíciese de:

|

|

|

|

|

| Soluciones líderes del sector | Normas de cumplimiento | Control de calidad | Formación y consultoría |

En Malvern PANalytical, compartimos el impulso del sector para operar de forma más sostenible. Con este fin, junto con nuestros propios objetivos de sostenibilidad operativa, apoyamos a nuestros clientes de aceites y productos petroquímicos para que cumplan sus objetivos medioambientales y aborden sus retos de producción.

Específicamente, al ofrecer un espectro completo de soluciones de análisis petroquímico y de petróleo para todas las etapas de la cadena de valor, permitimos a estos clientes optimizar sus procesos para lograr eficiencia y garantizar que sus materiales son de la más alta calidad posible con el menor impacto ambiental posible.

Si tuviera que valorar mi experiencia con Malvern PANalytical, le daría fácilmente el 9/10.

Sus productos son muy eficientes desde el punto de vista analítico y el servicio técnico postventa está a la altura de nuestras expectativas.

Marina Boccongelli - Total Bélgica

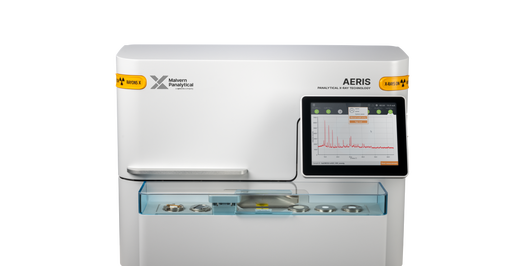

Nuestros analizadores petroquímicos y petroleros ayudan a los productores a optimizar sus materiales, procesos y productos, ya sea durante la exploración o el control de calidad.