We interviewed Professor Yanagitani of the Metal Materials Research Center, Industrial-Academic Collaboration and Research Promotion Organization, University of Hyogo. The Metal Materials Research Center has introduced the Morphologi 4 particle image analyzer and the FT4 powder flow analysis device.

We interviewed Professor Yanagitani of the Metal Materials Research Center, Industrial-Academic Collaboration and Research Promotion Organization, University of Hyogo. The Metal Materials Research Center has introduced the Morphologi 4 particle image analyzer and the FT4 powder flow analysis device.

In this article, we asked Professor Yanagitani about his current research, how he uses the devices and the activities of the Hyogo Metal Belt Consortium.

In 3D printing technology, the laser powder bed method is often used. We are researching the metal powder materials used in this case. Almost all materials used in the laser powder bed method are gas-atomized powder materials because they are spherical and have good fluidity. They also have a track record of being used for various purposes other than 3D. For this reason, 3D printing manufacturers have used gas-atomized materials as the standard when developing printer equipment.

However, materials made using the water-atomization method can be produced more cheaply than those made using the gas-atomization method. This is because water-atomized powder has long been used in the field of sintering and has good productivity levels. In order for 3D printers to become more widespread in the future, we thought it was important that the materials used for them were inexpensive.

Then, by chance, when I looked at the Epson Atmix powder, I noticed that it was a beautifully spherical powder, just like gas-atomized powder. I thought this could be used for 3D printing. When I compared it to the gas-atomized powder material I was currently using, I noticed that the Epson Atmix powder was very similar. I thought maybe this could be used for 3D printing... so I used it in my laser powder bed, and it worked well!

This was just the beginning.

![[CS20241011-Adv Mfg 1] Picture1.png](https://dam.malvernpanalytical.com/48cd8add-8df8-494f-9411-b20600905c8c/Picture1_Original%20file.png)

Figure: Appearance photo of SUS316L powder: (a) Gas atomized powder, (b) Water atomized powder (manufactured by Epson Atomics), (c) Conventional water atomized powder. Source: Water-atomized powder L-PBF molding and evaluation technology, Akihiko Yanagitani, Specially Appointed Professor, University of Hyogo, Deputy Director of New Metal Materials Research Center

Upon investigation, it appears that water-atomized materials are primarily produced for use in MIM (Metal Injection Molding), where the goal is to create products with excellent surface quality by processing the raw material as spherically as possible, which leads to it being usable in laser powder beds.

Planetary gear modeling example

We were shown a model made using water-atomized powder. Above is an example of a planetary gear model, with six gears rotating and revolving around the object. The six gears were not added later, but were formed in the thickness direction from the start of the modeling, and are gears that will not come off, which is a feature of 3D modeling.

I had previously used the particle image analyzer, Morphologi 4. I knew it could measure particle shape, so I wanted to use it. When using materials for water atomization, it was necessary to see the particle shape in an image, so I decided to use Morphologi 4.

Furthermore, through the activities of the Hyogo Metal Belt Consortium, we have come to the need to measure the physical properties of other powder materials. For example, there are materials created by the plasma melting method. This method can also create composite materials of metal and ceramics, and can produce shapes that are closer to perfect spheres than other methods. In that case, we need detailed information on the particle shape, such as circularity, so we need to measure it with Morphologi.

Another reason we decided to use the FT4 powder fluidity analyzer was because we wanted to evaluate the fluidity of water-atomized powder. Water-atomized powders generally have smaller particle sizes than gas-atomized powders, and have poor fluidity, so they cannot be evaluated using the JIS(Japanese Industrial Standards)fluidity test. With the FT4, we can quantitatively measure shear force and viscous resistance, which can be used to evaluate fluidity. Soon after the introduction, companies conducting joint research in the consortium have expressed their desire to use it as well.

To be honest, I used to have the impression that image analysis devices like Morphologi 4 took a very long time to measure. Especially compared to the laser diffraction method, I felt that the measurement time was inevitably long. However, recently, the processing power of personal computers has improved, and I was surprised to see that the measurement time has been significantly shortened.

In addition, as operation is based around a microscope it is easy to understand. Since it can obtain a wealth of measurement data and perform detailed image analysis, I think it is very suitable for the activities of this consortium. Some companies have expressed an interest in using this device immediately after its introduction.

Furthermore, the fact that it requires only a small amount of powder is extremely important. Measurements can be performed with a small amount, about the size of a spatula, so it is very useful for conserving valuable materials.

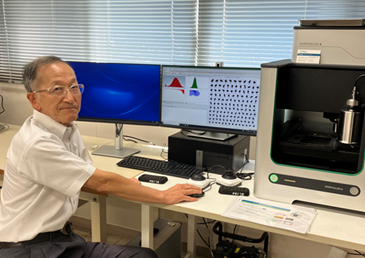

Professor Yanagitani and the Morphologi 4 particle image analyzer

For materials for laser powder beds, information such as fluidity and powder shape is important. FT4 can quantitatively grasp fluidity, allowing for a wide range of analysis. FT4 is a device with its own parameters, and powders can be compared with other powders to obtain data. This means that the data can be viewed relatively.

Thanks to FT4, we believe that we can also obtain data on the surface properties of particles. Since the data on the particle shape of powders measured with Morphologi 4 can be associated with the data measured with FT4, we feel that it is a very interesting device that can utilize both devices. We will be presenting some of the research results obtained using this device at World PM2024 (Yokohama).The research results will also be showcased at the joint booth of the Hyogo Metal Belt Consortium atformnext 2024in Frankfurt this November.

We would like to continue our research on the water atomization method in the laser powder bed method. The consortium's activities began when we decided to start research from powders, not just from modeling, when we were conducting research at the university. We are currently researching a variety of materials, including gas-atomization, water-atomization, and plasma melting methods.

For example, the plasma melting method can also be used to create composite materials. We have received consultations from companies that handle materials produced using the plasma melting method, and we have been conducting 3D printing using new powders. In the future, we will likely need to investigate the physical properties of these new materials, such as circularity and fluidity.

It is important that we explore unprecedented alloy compositions in this laboratory and understand their physical properties, as we believe that doing so will open up a wide range of possibilities.

New Metal Materials Research Center

The Seto Inland Sea coast is home to some of the nation's leading metal material manufacturing and processing technologies, forming the "Hyogo Metal Belt." In order to add value to these industries, the "New Metal Materials Research Center" was established as a base for research and development of materials.

Here, we aim to establish and disseminate metal powder and 3D modeling technologies with excellent hardness, heat resistance, and fine processing properties required for next-generation industries. In particular, to support small and medium-sized enterprises that are proactive in introducing and utilizing metal 3D printers, we work with companies that have advanced technologies and provide technical support through industry-academia collaboration.

The consortium provides its members with technical and management consultation, joint research, seminars and practical training, as well as a presentation event called Seeds Needs Matching, which is very popular among companies as a place to promote themselves and learn about the technologies of other companies. Members who do not have a business office in Hyogo Prefecture can also join and participate, so please contact us if you are interested.

Akihiko Yanagitani, Vice Director, Specially Appointed Professor

University of Hyogo New Metal Materials Research Center

Hyogo Metal Consortium

Profile: Joined Sanyo Special Steel Co., Ltd. in 1981 and was involved in the launch of the metal powder business. Became a specially appointed professor at the University of Hyogo in 2018 and a visiting professor at Osaka University in 2019. Engaged in metal powder research, product development and practical application. Served as a director of TRAFAM (Technology Research Association for Future Additive Manufacturing) from 2016 to 2021. Established the Hyogo Metal Belt Consortium in 2019 and is currently engaged in research, development and dissemination of metal 3D additive manufacturing as the deputy director of the University of Hyogo New Metal Materials Research Center and vice chairman of the consortium. Secretary of the 3D Metal Additive Manufacturing Committee of the Japan Society of Powder and Powder Metallurgy in 2020. Received the Japan Institute of Metals Technology Award in 2010 and the Japan Society of Powder and Powder Metallurgy Technology Achievement Award in 2022, among others.