The Zetasizer APS - the auto plate sampler - is an automated dynamic light scattering (DLS) instrument which enables scientists to prepare and measure large number of samples with unattended operation and a wide range of flexibility.

The APS maintains the samples at a well-defined temperature until the DLS measurements are performed. The temperature of the plate holder is controlled separately from the measurement cell temperature, by an external water bath. The temperature control of the plate holder allows the user to maintain the proteins under optimal condition, at temperatures between 4°C and 40°C (+/- 0.1°C), until their measurement.

The measurement flow cell is temperature controllable between 2°C and 90°C, with a precision of 0.1°C. This allows the user to perform repeatable thermal trend measurements of their sample to monitor sample stability in various buffers.

The Zetasizer software for the APS is based on standard operating procedures (SOPs) which are pre-defined measurement methods. In the SOPs, the user defines the sample characteristics, such as type, e.g. proteins, and solvent conditions, e.g. PBS buffer. Besides specifying the material and solvent used, the user can define the measurement temperature, temperature equilibration time, and sampling cleaning protocol.

The handling of sample, i.e. if the sample is to be returned to the well after measurement or disposed of to waste, is also user defined. For example, after a size measurement at room temperature, a non-denatured protein can be returned to the well, whereas a denatured protein, e.g. after a thermal scan, can be disposed of to waste.

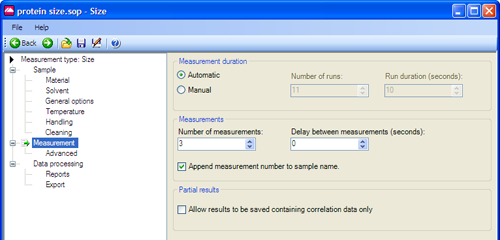

In the SOP dialogue, the user can define the number of repeat measurements, as well as the length of each measurement, to be performed on the sample (figure 1). The user can select automatic measurement duration, where the software determines the measurement duration based on the signal achieved or manual measurements where the user inputs the measurement run time and number of runs. The user can also select if they want to do more than one measurement of the sample to control sample stability.

|

The combination of sample handling and measurement setting selection provides great flexibility to the user in the speed and accuracy of measurements.

The SOPs ensure that samples can be re-measured using exactly the same measurement conditions.

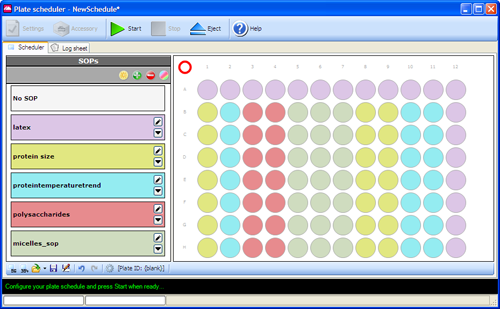

The Zetasizer APS measurements are set up in the software with the help of the plate scheduler. The plate scheduler is a graphical display of the plate indicating which SOP is used in which well.

The software allows the user several different SOPs on one multi-well plate. For example, a maximum of 96 SOPs can be used in a 96-well plate. As SOPs can be defined for different materials, the same plate could contain protein samples, nanoparticles or micelles in the different wells.

As well as combining different materials in the same plate, different types of measurements can be performed in the same plate. A number of samples can have their size measured at a certain temperature, while for another type of sample a thermal trend measurement can be performed to study the effect of thermal stress on protein stability. Figure 2 shows an example of a 96 well plate in which a number of different SOPs have been defined.

|

The separate temperature controls of the plate holder and the measurement cell allows the Zetasizer APS to be used to maintain the protein samples in optimal condition until measurement. In addition, thermal trend measurements between 2°C to 90°C with 0.1°C degree precision can be defined.

The plate scheduler allows the user to graphically set up size and thermal trend measurements of various samples from the same plate using a variety of different SOPs.