Producción de hierro

Para producir hierro y acero de alta calidad a un costo mínimo, necesita procesos eficientes, con el menor uso posible de combustible y energía, y flujos de materiales uniformes. No solo eso, sino que los procesos y los materiales optimizados también pueden ayudarlo a reducir costos y cumplir con los objetivos ambientales. Por ejemplo, las nuevas e innovadoras tecnologías de monitoreo de procesos ayudarán a habilitar nuevos métodos de producción de hierro que se pueden utilizar para lograr acero libre de CO2.

Sin embargo, para predecir y optimizar el comportamiento de su material, debe supervisarlo continuamente en todas las etapas del proceso y responder rápidamente a los resultados. Con las soluciones industriales de Malvern Panalytical, puede analizar la composición mineralógica, elemental, estructural y del tamaño de partícula de los sinterizados de hierro, los gránulos, el hierro con reducción directa y el acero en cuestión de minutos, para realizar operaciones con una verdadera garantía de futuro.

Sus soluciones:

Monitoreo de sinterizado de hierro |

Análisis de hierro directamente reducido |

Control de calidad del acero |

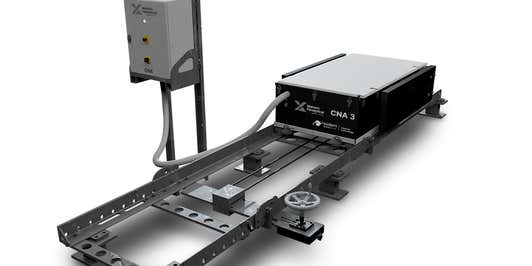

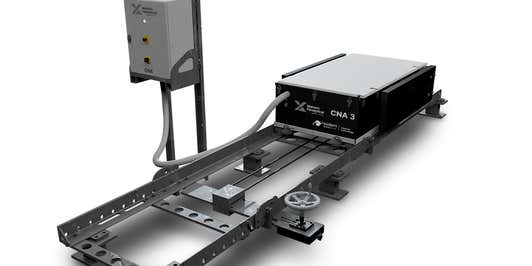

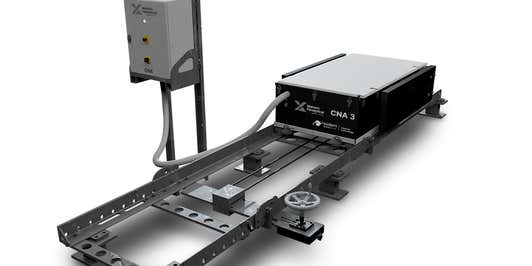

La producción de sinterizado eficiente y segura comienza con la garantía de que la planta de sinterizado obtenga el mejor material de entrada. Para garantizar esto, debe monitorear la composición elemental de sus mezclas y materias primas intermedias. Gracias a nuestros analizadores de sinterizado de alto rendimiento basado en neutrones CNA3, lo volvemos fácil.

Pero eso no es todo: Para evitar pruebas físicas y químicas húmedas caras y que llevan mucho tiempo y lograr contramedidas más rápidas, también es esencial monitorear la composición de la fase y los parámetros del proceso del sinterizado de hierro mismo. Estos parámetros pueden incluir Fe2+, FeO, el índice de base, la degradación a baja temperatura, la resistencia del sinterizado y la capacidad de reducción. Nuestras soluciones de XRD únicas pueden analizar todas estas propiedades, y nuestras soluciones de XRF también pueden monitorear la composición elemental de su sinterizado.

Mediante el monitoreo del tamaño de las partículas, la composición elemental y la composición mineralógica de la alimentación de gránulos, puede predecir condiciones de peletización, como la resistencia a la compresión, más fácilmente, y optimizar estas propiedades para lograr gránulos de mineral de hierro de alta calidad. Con nuestras soluciones de difracción láser en línea, analizadores elementales de cinta transportadora y soluciones de XRD y XRF de laboratorio, realizar este análisis es más fácil que nunca.

También conocido como hierro esponja, el hierro de reducción directa (DRI, del inglés direct-reduced iron) se produce mediante la reducción del mineral de hierro mediante el uso de un gas producido a partir de gas natural o carbón. Para que este proceso sea lo más eficiente y seguro posible, se debe monitorear el contenido metálico de hierro, la metalización, el contenido total de carbono, el contenido mineralógico y la composición elemental. Nuestras soluciones de difracción de rayos X y los espectrómetros de fluorescencia de rayos X analizan estos parámetros en minutos.

Cuando se trata de la fabricación de acero, es esencial un control de proceso y calidad riguroso, tanto para la materia prima como para los productos finales. Esto requiere un análisis químico rápido y preciso, así como una caracterización microestructural de los metales y las aleaciones. Y este análisis debe causar una interrupción mínima de la producción. Al mismo tiempo, también hay presión creciente de los consumidores y los organismos reguladores para que los fabricantes de acero trabajen por los objetivos de sostenibilidad como el acero libre de CO2.

Nuestros instrumentos de XRF y XRD, junto con nuestras soluciones de calibración y automatización, ayudan a los fabricantes de acero a satisfacer este desafiante conjunto de exigencias.