Polyethylene (PE) is one of the world’s most widely used polymers and despite its simple structure finds its way into our everyday life in many applications, from pipe lining and wire coatings to shopping bags. The properties of the material are highly dependent on the molecular weight, and analysis of this parameter by gel permeation chromatography (GPC) is vital for research and quality control. The main challenge confronted by this analysis is that polyolefins, including polyethylene, are insoluble at room temperature. In order to dissolve these polymers, temperatures as high as 140-160°C are required to keep them in solution.

In an attempt to alter the properties of polyolefins to suit the needs of various applications, modifying the polymer with suitable fillers has become very common. This presents a new challenge to the molecular weight analysis process, as the need to remove these fillers from the polymer mixture prior to GPC injection makes the analysis more challenging, as filtration at high temperature is required. This is normally performed on the bulk solution at 140-160°C and represents both a practical as well as a health and safety challenge.

Here, we report the analysis of carbon filled PE using a Viscotek High Temperature GPC system without any external filtration of the sample before injection.

The Viscotek High Temperature GPC (HT-GPC) is designed specifically for the characterization of polyolefins, bringing advanced triple detector technology to this demanding application.

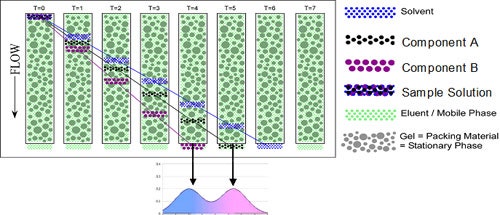

The principle of GPC/SEC is the separation of molecules based on their hydrodynamic radius (Rh) or volume (Vh), rather than their molecular weight as is often assumed. The separation process takes place in a column which is packed with porous, microparticulate material. Because of their size, the larger molecules are excluded from some of the pores in the packing material and therefore elute faster through the column than the smaller molecules. In effect, the molecules are sorted by size, with the largest eluting first and the smallest last. The figure below illustrates the mechanism of GPC separation.

|

Triple detection sets the standard for current GPC/SEC technology and has become the preferred method for characterizing polymers. It employs a concentration detector, viscometer and light scattering detector acting in concert, with each detector providing complementary but different information:

The light scattering detector provides a direct measurement of absolute molecular weight and eliminates the need for column calibration. The viscometer detector provides a direct measurement of intrinsic viscosity or molecular density, and allows the determination of molecular size, conformation and structure. Concentration is measured with a differential refractive index detector (RI), and is necessary for the determination of both molecular weight and intrinsic viscosity.

Triple detection is able to accomplish all this - and more - without the need for lengthy column calibration. Simply running a single narrow standard will verify the instrument constants as well as performing corrections for inter-detector volume and peak broadening effects. The peak broadening calculations are critical to good multi-detector GPC/SEC and the calculations used in the OmniSEC software are the result of over 20 years experience with this type of algorithm.

The sample was supplied as polyethylene pellets filled with approximately 10% carbon black. The sample preparation step, which for these samples would normally include a hot, bulk filtration, is important as filler reaching the column would severely reduce its lifetime. However, in this case the preparation is enormously simplified by virtue of one of the Viscotek HT-GPC unique features; an in-line, self-cleaning filter system which only filters the small amount of sample that is transferred to the column. The Vortex eliminates the need to transfer hot sample from a preparation vial to an autosampler vial as the HT-GPC filters the sample as part of the injection procedure. This increases efficiency, enhances precision and promotes safety by removing the operator from the sample preparation process.

About 30mg of the material was accurately weighed and placed into a 40ml glass vial containing a stirring bar. 10ml of stabilized TCB (1,2,4-Trichlorobenzene) was added, the vial sealed with a Teflon coated cap, placed into the Vortex Auto Sampler and left to stir at 160°C for 3hrs. After injection, and before entering the GPC column the sample is filtered automatically to remove the carbon filler. During the analysis, the programmed sequence cleans the filter by back-flushing, in preparation for the next sample.

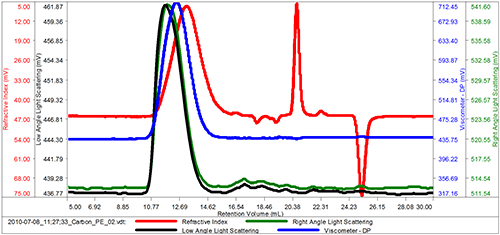

Figure 1 shows the signals from the differential refractometer (RI), right angle light scattering (RALS), low angle light scattering detector (LALS) and differential viscometer detector. 7 repeat measurements were made using a volume of 200 μL with TCB (1,2,4-Trichlorobenzene) as the eluent, using a flow rate of 1.0 mL/min with three mixed-bed columns in series. The whole system, including columns, detectors and inter-detector tubing was maintained at a constant temperature of 150 °C. The inter-detector volumes, band broadening and instrument constants were determined using a narrow polystyrene standard. The value of dn/dc used for the PE sample in these measurements was 0.102 mL/g.

|

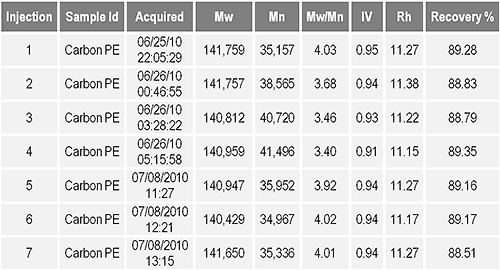

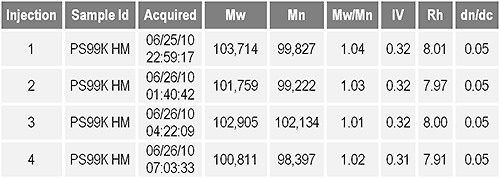

Key to tables 1 and 2

Mw: Weight average molecular weight (Dalton)

Mn: Number average molecular weight (Dalton)

Mw/Mn: Polydispersity

IV: Intrinsic Viscosity (dl/g)

Rh: Hydrodynamic Radius (nm)

dn/dc: Refractive index increment (ml/g)

The aim of this study was to determine the capability of the instrument to handle samples filled with insoluble filler. In this case approximately 10% carbon black.

Table 1 demonstrates the precision of the analysis of the carbon filled material over 7 repeats showing that the performance of the system had not been affected by analyzing this material. To confirm this, the sequence of measurements included 4 interleaved injections of polystyrene 99K standard to determine the system stability. The results in table 2 show that the system demonstrated excellent stability.

|

|

The carbon filled sample was successfully analyzed by the Viscotek HT-GPC system and reproducible results were obtained and reported. The presence of the carbon black filler in the HT-GPC samples had no detrimental impact on the analysis and was successfully removed by the automatic filtration system. This means that filled polyolefins can now be analyzed by HT-GPC with minimal sample preparation and no bulk sample filtration.