The Zetasizer Auto Plate Sampler (APS) is a dynamic light scattering instrument that automates the measurement of size of proteins, viruses and nanoparticles samples from any industry standard 96 or 384 well plate.

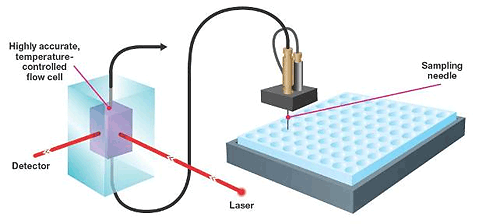

To ensure that accuracy and sensitivity requirements are met, the sample is transferred from the temperature controlled plate to the precision quartz cell (figure 1).

|

The use of such a sampling method provides great flexibility allowing a range of protocols to be performed on a single plate. For example, size measurements can be used to detect the presence of aggregates or melting point measurements can be used for studying protein stability and determination of the denaturation temperature.

The APS uses well proven sampling technology to transfer the sample from the plate to the cell. This method of sampling is widely used by HPLC auto samplers and is a well tested and accepted technology.

To ensure that the sample structure or stability is not altered in any way, the sampling regime has been designed to have low shear and is significantly lower than standard laboratory pipetting techniques.

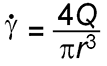

The shear rate (ϔ) encountered during any extrusion process is related to the radius of the tubing (r) and the volumetric flow rate (Q) by the following expression [1]:

|

By measuring the volumetric flow rate (the volume dispensed in a given time) and the internal radius of the smallest tubing, it is therefore possible to estimate the shear rate encountered during sampling.

The smallest diameter of tubing used in the Zetasizer APS is 0.25mm with a default flow rate of 10µl/s. The smallest part of a typical 200ml pipette tip has been measured to be 0.5mm.

Table 1 shows shear rates calculated for the Zetasizer APS and for a typical 200ml pipette tip with typical pipetting flow rates. In normal operation, an automatic pipette will have flow rates of between 100 and 200µl/s.

| Diameter of Narrowest Tubing (mm) | Diameter of Narrowest Tubing (m) | Volumetric Flow Rate (µl/s) | Volumetric Flow Rate (m3/s) | Shear Rate (s-1) | |

|---|---|---|---|---|---|

| Zetasizer APS | 0.25 | 2.5 x 10-4 | 10 | 1.0 x 10-8 | 6518 |

| Autopipette | 0.50 | 5.0 x 10-4 | 100 | 1.0 x 10-7 | 8148 |

| 0.50 | 5.0 x 10-4 | 150 | 1.5 x 10-7 | 12223 | |

| 0.50 | 5.0 x 10-4 | 200 | 2.0 x 10-7 | 16297 |

The results in table 1 confirm that the shear rate value obtained for the default flow rate in the Zetasizer APS is lower than for typical flow rate values used in an automatic pipette.

To further ensure that the integrity of the samples is maintained during the duration of the measurements, the temperature of the plate is carefully controlled.

The temperature of both the plate and the cell can be set independently. The cell temperature is settable between 2 and 90oC to a precision of 0.1oC. The plate temperature is settable between 4 and 40oC which means that the samples are kept under optimum conditions throughout the entire measurement procedure.

The plates can be sealed to minimize sample evaporation prior to measurement and the humidity controlled measurement zone prevents condensation when measuring at low temperatures.

The use of a sampling method provides great flexibility allowing a range of protocols to be performed on a single plate. Either a single method for the whole plate or potentially a different method for each well can be defined.

The sampling regime used in the Zetasizer APS ensures that sample integrity is preserved during transfer from the plate to the cell and that no aggregation of the sample occurs during transfer.

The ability to maintain the whole plate at a low temperature while samples are being measured at a different temperature ensures that sample integrity is ensured throughout the entire measurement sequence.

[1] Handbook of Elementary Rheology (2002) Howard A. Barnes, University of Wales, Institute of Non-Newtonian Fluid Mechanics