석유 굴착 장비에서부터 석유 화학 공장에 이르기까지 수익성 있고 혁신적이며 내구성 있는 자산을 운영할 수 있도록 지원합니다

오일 및 석유 화학 산업 전반에 걸쳐 환경 영향을 개선하기 위한 추진력이 높아지고 있습니다. 동시에 오일 가격의 변동이 있는 상황에서 생산자는 최소한의 비용으로 최대의 효율성과 품질을 달성하기 위해 공정을 지속적으로 최적화해야 합니다.

위험 화학 물질, 부식, 풍화, 자동 무인 시설로의 전환 등 여러 가지 어려움 속에서 이러한 모든 요구 사항을 충족하기는 어려울 수 있습니다. 업계 최고의 솔루션, 품질 관리, 규정 준수 표준 및 교육을 통해 이러한 문제에 더욱 쉽게 대처할 수 있습니다. 어떤 식으로 가능할까요? 고품질 연료 및 중합체를 확보하고 불순물을 파악하며 폐기물을 줄이고 생산 공정을 간소화할 수 있습니다.

장점:

|

|

|

|

|

| 업계 최고 솔루션 | 규정 준수 표준 | 품질 관리 | 교육 및 컨설팅 |

Malvern Panalytical은 보다 지속 가능한 사업을 운영하기 위한 업계의 추진력을 공유합니다. 이를 위한 당사의 자체적인 지속 가능성 목표와 함께 Malvern Panalytical은 석유 및 석유 화학 고객들이 환경 목표를 달성하고 생산 문제를 해결하도록 지원합니다.

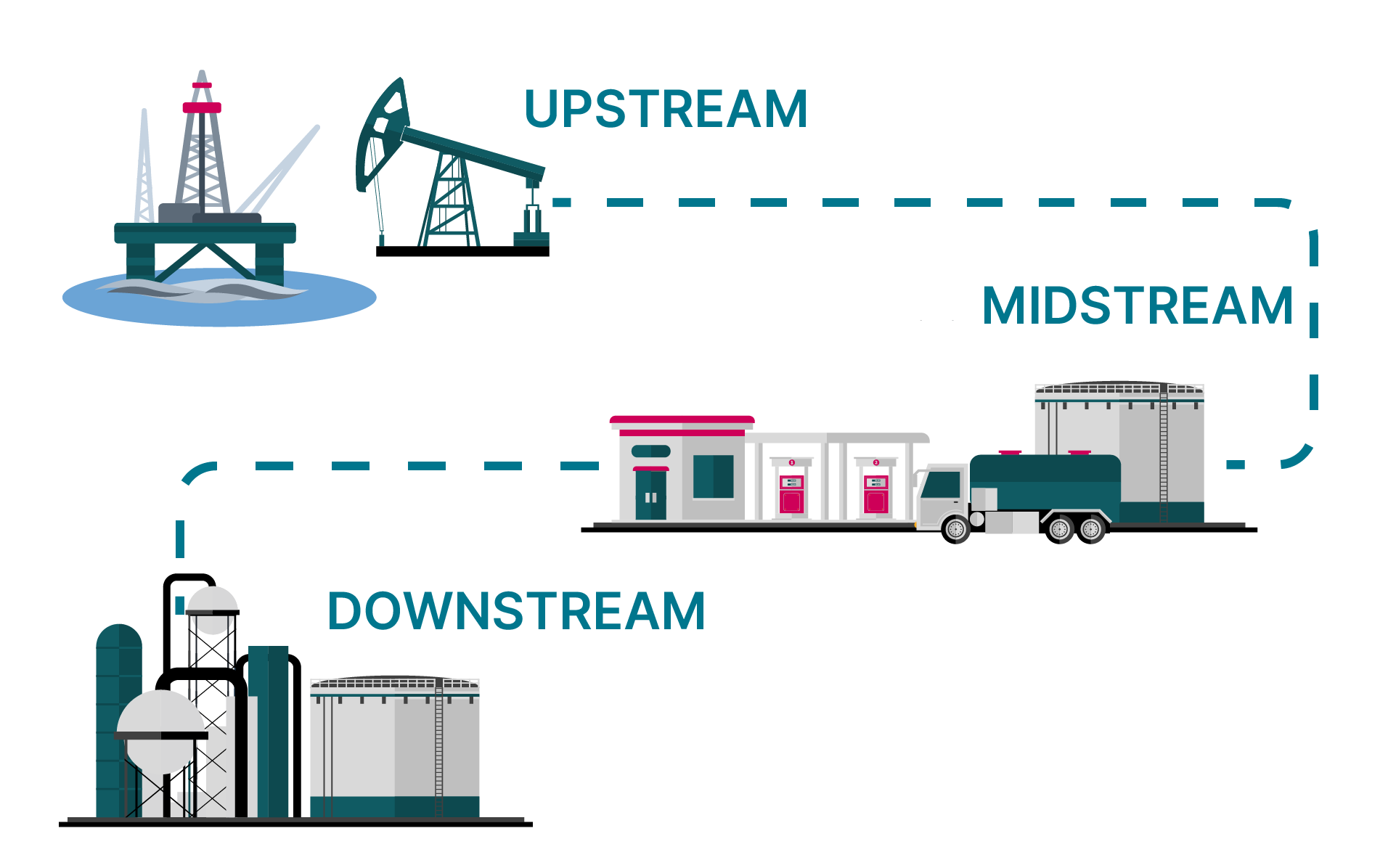

특히, 가치 사슬의 모든 단계를 위한 모든 범위의 석유화학 및 석유 분석 솔루션을 제공함으로써 고객들이 공정 효율성을 최적화하고 환경에 대한 영향을 최소화하면서 가능한 최고 품질의 원료를 사용하도록 지원합니다.

"Malvern Panalytical에 대한 경험을 평가한다면 당연히 10점 중 9점을 줄 것입니다.

Malvern Panalytical의 제품은 분석 측면에서 매우 효율적이며, 애프터세일즈 기술 서비스는 기대에 부응합니다.”

Marina Boccongelli - 벨기에 전체

제조업체들은 당사의 석유 화학 및 석유 분석기를 통해 탐사 중이거나 품질 관리 중 언제라도 원료, 공정 및 제품을 최적화할 수 있도록 도와줍니다.