The Morphologi instrument is a high sensitivity particle analyzer that provides statistically valid information on particle size and shape. When performing measurements on the Morphologi, one of the most important things to consider is the preparation of the samples. In order to ensure that comparisons between samples are made on the actual morphology of the particles and not the way the particles are orientated, it is important that particles are consistently orientated. The application note titled "Image analysis and the importance of particle orientation" discusses the issues in more detail.

This application note will introduce a few different methods of sample preparation for measurements to be performed on the Morphologi image analyser that can be considered during method development and if necessary adapted depending on the sample to be measured.

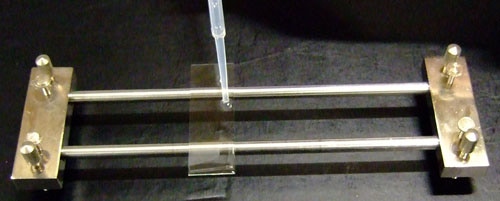

If the particles in the sample are large and free flowing manual dispersion by simply sprinkling the sample onto a large glass plate can be considered. For this option a walled plate and a retaining shroud are also available (Figure 1 ).

|

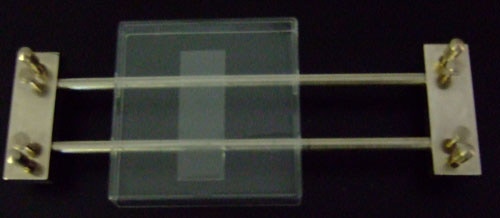

The sample preparation device, SPD 1300 (Figure 2) can be used to disperse dry powders as described in its user manual. When preparing samples using the SPD it is important to consider the dispersion pressure. It is a good idea during method development to perform a pressure titration by preparing samples at different pressures. This will allow verification that the most appropriate dispersion pressure is adopted for sample preparation and that it does not cause damage to the particles or lead to particles becoming affected by static. It is also important to consider the total cycle time. If fine particles are present in the sample the dispersion device should remain closed for longer to allow the fine particles to settle and so to avoid biasing the sample dispersion towards larger particles.

|

For some samples it is appropriate to disperse them by an evaporation technique. This is particularly useful for very fine particles, if the SPD causes static or breakage, or if the sample is polydisperse making wet methods difficult. The sample must not be soluble in the solvent used and it is often a good idea to add a surfactant to the solvent system to prevent agglomeration of particles. A typical solvent system employed at Malvern is freshly prepared 0.01 % lecithin in iso-octane (W / V). Combinations of other organic solvents and surfactants such as tween or span can also be used for this technique as can a low boiling point silicone oil such as hexamethlydisilonane.

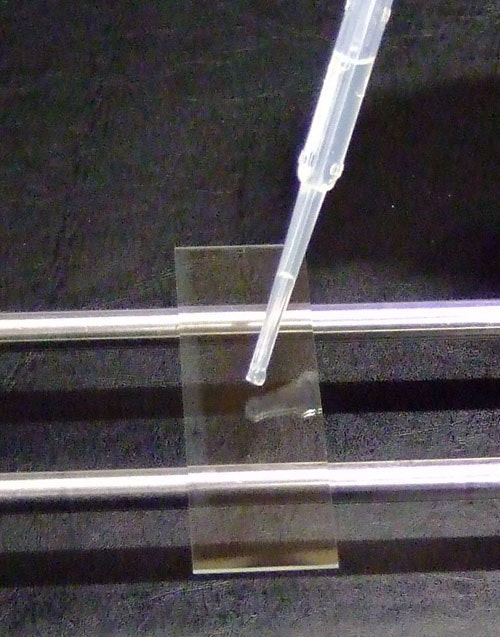

As a starting point, an aliquot of approximately 2 mg of sample (depending on the particle size) is placed into a sample vial and around 4 ml of the solvent system is added. Depending on how fragile the particles are, or how agglomerated, vortex mixing and/or ultrasonication is applied to the sample suspension. A clean glass slide is then covered with approximately 0.5 ml of the sample suspension as shown in Figure 3 (note it is important to ensure that the entire slide is covered by the suspension).

|

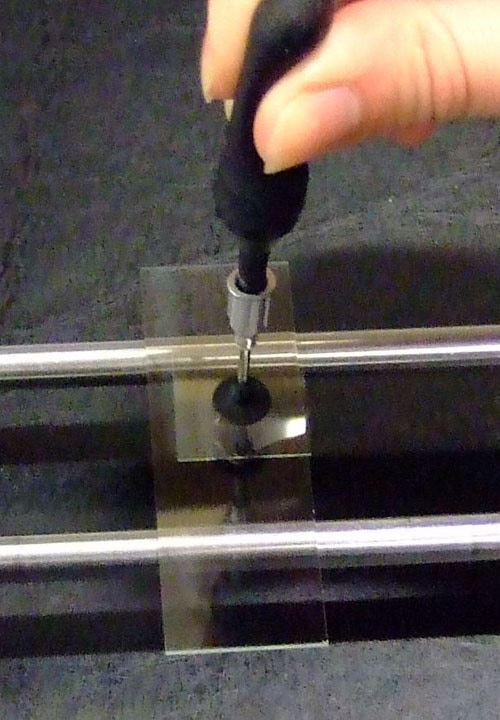

Some sort of cover should then be placed over the slide to encourage slow evaporation and to prevent contamination (Figure 4 ).

|

The solvent is then left to evaporate and experience shows that slower evaporation results in less "pooling" of the sample. Once dry, the slide can be measured on the Morphologi image analyser. During method development the concentration of the sample in the solvent system can be adjusted along with the amount of ultrasonication applied until a reproducible dispersion is obtained.

Samples can be dispersed in oil and this is particularly good for monodisperse samples. A small amount of sample is placed in a sample vial and the appropriate oil is added. The sample should then be shaken, ideally using a vortex mixer, in order to disperse the particles. Sometimes, ultrasonication is also required in order to disperse loose agglomerates. During method development several trials may be required to determine the most appropriate concentration of sample in the oil for measurement.

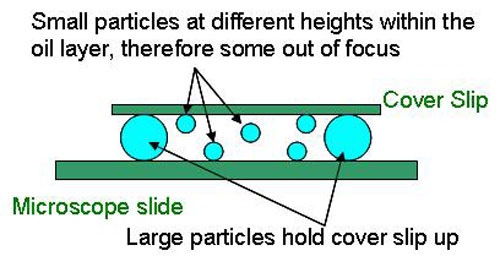

Once the particles are dispersed in the oil a few drops of the dispersed sample should be placed on a clean microscope slide (Figure 5 ) and a cover slip placed on top (Figure 6 ) which will encourage the oil to spread out. It is important to keep the layer of oil as thin as possible and often it is necessary to leave the sample to settle for a few minutes before a measurement can be performed. If the sample is too polydisperse and the oil rather viscous, fine particles may be held at different heights within the oil layer and thus at different positions in the objective's depth of field. This means many fine particles may be out of focus making measurements difficult (Figure 7). Sometimes this can be overcome by using an oil which is less viscous and allowing the particles to settle to bottom of the oil layer before performing a measurement.

|

|

|

If the particles are transparent and the refractive index of the particles and that of the oil are similar it can be difficult to get good contrast. This prevents the particles from being detected well. In this case oils with different refractive indexes can be tried.

Oils typically used for this type of dispersion are: mineral oil, silicone oil (eg poly(dimethtlsiloxane)), paraffin oil, Iodo-napthalene oil. Note care should be taken to use only glass pipettes and vials when using the latter oil.

If samples are not soluble in water it is also possible to adopt a similar technique using water as the dispersion media, often with a small amount of surfactant added to prevent agglomeration of particles. In this case it may also be necessary to put oil around the edge of the cover slip to prevent the water evaporating during the measurement.

There are many different ways to prepare samples for measurement on the Morphologi image analyser and this application note has covered some options including dry dispersions, wet dispersions which are measured wet and wet dispersion which are measured dry. These techniques permit the morphological measurements of a wide range of sample types by image analysis.

As with all sample preparation techniques for any type of analysis it is important that for whichever technique is deemed to be appropriate for a specific sample that tests are carried out during method development to check the reproducibility and robustness of the method.