Exploitation minière du minerai de fer

Améliorer la définition des blocs de nuances et réduire les coûts d'enrichissement du minerai de fer

Comprehensive turnkey solutions for elemental analysis of all Rare Earth Elements (REEs). Download now

Download nowAméliorer la définition des blocs de nuances et réduire les coûts d'enrichissement du minerai de fer

La diminution de la qualité des gisements de minerai de fer existants ou nouveaux nécessite des solutions prédictives pour trier et mélanger efficacement le minerai de fer afin d'obtenir un enrichissement et un traitement en aval optimaux et rentables. La composition élémentaire et minéralogique et les modèles prédictifs de l'évolutivité, sur la base de paramètres métallurgiques – comme les constituants lavables – jouent un rôle important pour les producteurs de minerai de fer.

Nos solutions surveillent l'ensemble des processus de fabrication du fer, de l'analyse directe sur les courroies de transport à l'analyse en laboratoire, en passant par le contrôle qualité automatisé complet du minerai de fer, de l'aggloméré de fer, du préréduit, de la fonte brute et des granulés de minerai de fer. Tout au long du processus de production de minerai de fer, nous proposons des solutions analytiques sur mesure pour les géologues en exploration, les planificateurs d'exploitations, les ingénieurs de process, les responsables qualité et les géométallurgistes.

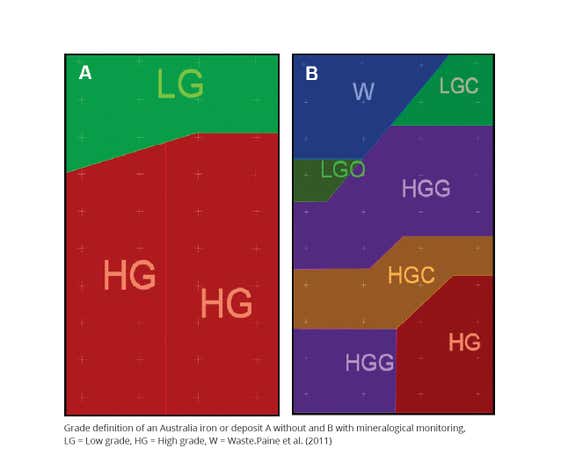

Avant d'extraire le minerai de fer, les gisements doivent être évalués pour connaître leur distribution en termes de teneur, afin d'optimiser l'exploitation de la mine, l'utilisation du budget de forage et le choix de l'équipement pour l'enrichissement du minerai de fer.

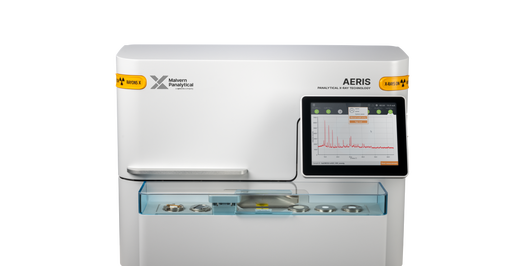

Nous proposons des solutions analytiques qui permettent de définir la teneur du gisement directement sur le terrain grâce aux analyses minéralogique (NIR) et élémentaire (XRF). Les solutions de laboratoire, adaptées aux exigences spécifiques de chaque mine, fournissent des informations précises quel que soit leur format : de paillasse, autonomes ou entièrement automatisées.

Notre expertise dans la préparation d'échantillons de minerai de fer, en particulier dans la production de disques en verre de haute qualité à l'aide de machines de fusion, est la condition préalable à une analyse élémentaire précise, conformément aux normes internationales.

Définition de la teneur du minerai de fer

Grâce à notre expertise, les exploitants de mines de fer peuvent définir la teneur du minerai, assurer une exploitation précise de la mine et prévoir la possibilité d'enrichissement du minerai de fer. Ainsi ils peuvent économiser plus d'un million de dollars par bloc dont la teneur aurait été incorrectement classée.

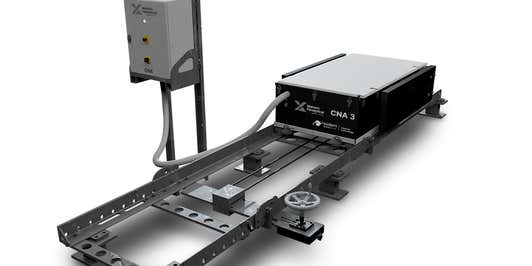

Nos solutions d'analyse en ligne (élémentaire et minéralogique) directement dans la mine permettent le tri du minerai et la prise de mesures rapides en cas de modification de la composition du minerai de fer afin de produire le mélange optimal pour le traitement en aval.

Cela permet d'économiser plusieurs millions de dollars par mois en opérations minières, car l'enrichissement du minerai de fer augmente considérablement les coûts par tonne de minerai.

Le contrôle de la teneur en humidité sur la courroie de transport (technologie proche infrarouge), ainsi que la surveillance précise de la composition du minerai de fer avant l'expédition, assurent une qualité constante du minerai afin d'éviter les pénalités.

Gestion des déchets

La gestion des déchets est extrêmement importante pour une exploitation et un enrichissement durables et sans danger du minerai de fer. Des solutions d'analyse dédiées pour l'analyse élémentaire, la caractérisation de la taille et de la forme des particules, la surveillance du potentiel zêta et la caractérisation des minéraux argileux assurent des opérations minières durables.

Pour traiter efficacement le minerai de fer en vue d'une production d'acier de haute qualité, une surveillance fréquente de la teneur du minerai est indispensable à toutes les étapes du traitement en aval. Indépendamment de la méthode de fabrication du fer, l'utilisation des carburants et de l'énergie pendant le frittage, le bouletage et la réduction directe du minerai de fer doit être optimisée pour rester compétitif et obtenir des produits respectueux de l'environnement.

La surveillance en temps réel de la taille des particules du concentré avec notre solution de diffraction laser en ligne permet d'assurer l'obtention de boulettes de minerai de fer de haute qualité et de prévoir les conditions de bouletage.

La composition élémentaire des mélanges bruts pour la production de boulettes ou d'agglomérés peut être surveillée en ligne sur la courroie de transport minière à l'aide de nos analyseurs à neutrons ou en laboratoire à l'aide de nos spectromètres de fluorescence X, pour les industries à haut débit.

Composition minéralogique

La connaissance de la composition minéralogique des boulettes de fer, de l'aggloméré ou du fer préréduit permet de prévoir leurs propriétés et leur comportement dans le haut fourneau. Nos diffractomètres à rayons X industriels, associés à des méthodes statistiques, peuvent analyser les paramètres physiques en quelques minutes :

Cela évite l'utilisation de produits chimiques humides dangereux et de tests physiques chronophages, pour une manipulation des échantillons en toute sécurité.