The best tasting coffee comes from whole coffee beans which have been freshly ground minutes before brewing. Control of the grinding conditions is critical, as incorrect milling can significantly impact the properties of the ground material and, as a consequence, the coffee flavor. Here, the use of laser diffraction in measuring the particle size of ground coffee is discussed along with the impact of particle size changes on flavor release.

The nature of the process used to produce ground coffee from the bean can have a significant impact of the final product taste. The key factors which need to be considered include the degree of roasting, with longer roasting times yielding a stronger taste, and the particle size of the ground material. The particle size must be controlled in order to ensure that the desired flavor is achieved during brewing within a reasonable time period. If the particle size is too large then brewing may take many minutes. Milling to a finer particle size increases the overall particle surface area, leading to more rapid extraction of any flavor components. However, the extraction of bitter components during brewing becomes more likely. Very fine grinds also pack together more closely, giving a greater water resistance in the coffee machine. This causes the pressure required to push water through the grind during brewing to increase, again affecting the final taste.

The particle size of coffee has traditionally been measured using sieve-based methods. Although sieving has provided a means of differentiating between different grinds, it is both laborious and does not provide an accurate assessment of the amount of fine particles produced during milling. This lack of ability to resolve changes in the fine fraction limits the capacity of the technique to help control the quality of the final product.

|

Given the limitations of sieving, laser diffraction has become widely accepted for ground coffee analysis. Laser diffraction systems, such as the Mastersizer 3000, are extremely easy to set up and methods can be automated to provide robust results without constant user intervention. The measurements are also rapid, providing full size distributions in a few seconds. The technique is therefore well suited to the requirements of production and quality control.

|

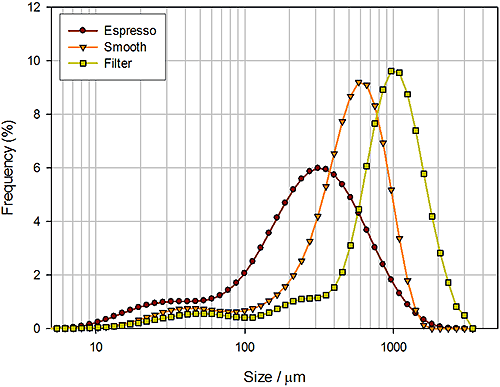

The link between particle size and taste can be shown by comparing the particle size distributions of different pre-ground coffee products. In figure 1, the size distributions for Filter, Smooth Roast and Espresso coffees are compared. Characterization of each sample was carried out using the Mastersizer 3000 equipped with the Aero S dry powder dispersion unit. The wide dynamic range of the Mastersizer system enables very large particles to be detected (up to 3.5mm in size) as well as allowing the content of very fine particles to be assessed. The results show that the Espresso product contains a significant fine fraction, which yields its characteristic bitter taste. As the particle size of the coffee increases, the taste produced becomes smoother.

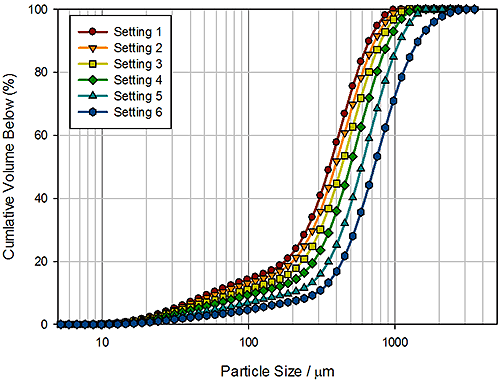

Figure 2 shows how the particle size distribution of coffee ground using an electric grinder changes as a function of the grinder gap setting. In this case, lower numbered settings related to a smaller grinder gap whereas higher settings related to a larger grinder gap. The results obtained show the ability of the Mastersizer 3000 system to track the changes in particle size as the grinder settings are adjusted. The particle size deceases as the gap size is reduced, with a significant proportion of fines being observed at the smallest setting. These fines would be expected to yield a coffee which brews rapidly but produces a bitter taste, such as an Espresso coffee. The coarse grind produced for larger gap sizes would be more suitable for use as a filter coffee.

|

|

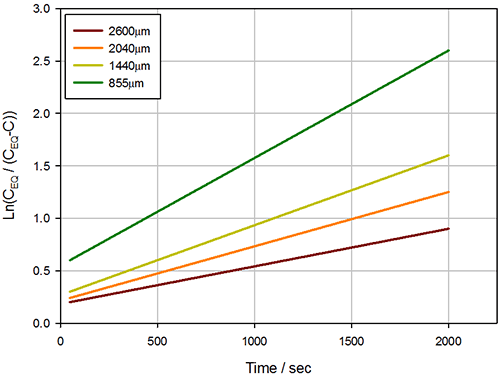

The link between particle size, brewing time and taste development can also be shown experimentally. Smith et al. [1] used a spectroscopic technique to monitor how the infusion of soluble coffee compounds into hot water changes according to the size of the coffee particles. The results obtained are shown in figure 3 and confirm that reducing the particle size significantly increases the rate of infusion. The increase observed is not linear with respect to the decrease in particle size. This is because the process of infusion is dependent on the surface area of the coffee within the suspension, which itself increases according to the square of the particle diameter.

The particle size of ground coffee is an extremely important parameter in determining the final characteristics of the brewed product. Care needs to be taken during grinding to ensure that the resulting particle size matches the required taste profile for the product being made. The Mastersizer 3000 laser diffraction system provides a robust method for monitoring the particle size of coffee which, in turn, can enable better control of grinding processes and improved product consistency.

[1] A. J. Smith and D. L. Thomas, "The Infusion of Coffee Solubles Into Water: Effect of Particle Size and Temperature", ExemplarChem 2003