Selective laser sintering (SLS) is an additive manufacturing technique that uses a laser to selectively sinter powdered material (typically nylon or polyamide) to create a solid 3-dimensional structure. SLS has the potential to produce serial parts with high quality and high mechanical properties. Although the technique has been noted to have high potential for many years, there remain some challenges facing this approach.

One of these challenges is cost. The main contributor to the high cost of building serial parts using SLS is the high cost of polyamide 12.[1] This is compounded by the fact that less than 30 % of the powder employed in the process is used to build the part. Coupling this with the high cost of polyamide/nylon 12 (PA12) drives the need to reuse the material multiple times. On paper this makes sense but in practice, it is not always that straightforward as the material is prone to aging during the build process which can limit its reuse.[2]

Material aging takes place when the powder is exposed to temperatures near the melting point of the polymer, changing the materials thermal and physical properties. To minimize these effects and to compensate for the material used in prior builds the reused powder (part cake) is blended with virgin powder, although achieving consistency can be difficult.[3] In some cases, the aging process can prove beneficial, such as sintered parts having increased mechanical properties.

To better control or to deal with aging, the mechanism responsible for the material changing must be firstly understood and this has been the focus of Prof. Katrin Wudy’s research during her time at Friedrich-Alexander-Universität (FAU) Erlangen-Nürnberg in Germany. Prof. Wudy was recently appointed as Professor for Laser-based Additive Manufacturing at the Technical University of Munich (TUM).

Prof. Wudy has used Malvern Panalytical multi-detection GPC system to investigate the influence of processing time and temperature on molecular changes and thermal properties of polyamide 12 in selective laser sintering. Multi-detection gel permeation chromatography (GPC) combines refractive index (RI), right and low angle light scattering detectors (RALS and LALS) and a differential viscometer, to give detailed information absolute molecular weight and molecular structure. This has proved crucial to better understand the aging of SLS PA12 in Prof. Wudy’s work.

For the following investigations an unmodified virgin polyamide 12 powder type PA 2200 from the supplier EOS GmbH, Germany was used. SLS experiments were carried out at a commercial SLS system Sinterstation 2000 from the supplier DTM Corp. and at a research selective laser sintering (SLS) system, which was build-up for the Collaborative Research Center 814 – Additive Manufacturing homed at the Friedrich-Alexander-Universität Erlangen-Nürnberg.

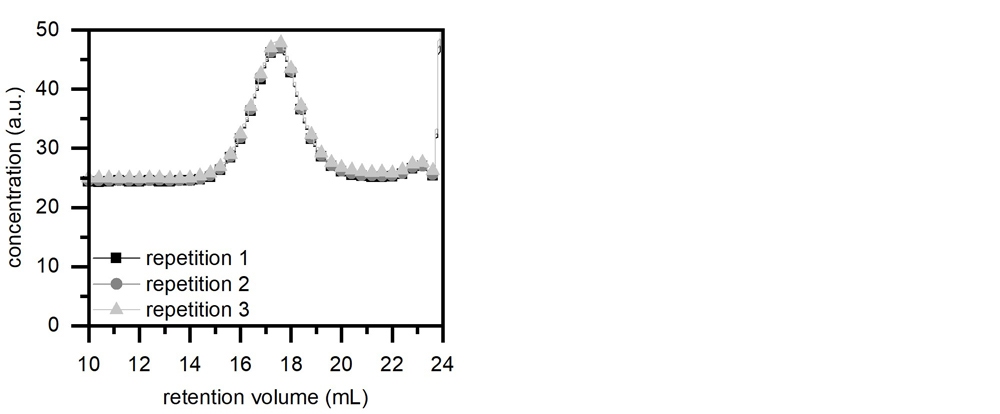

Firstly, the reproducibility of the aging was tested when the process variables were held constant. Presented below in figure 1 are the overlaid RI and RALS chromatograms of the build repeats. The chromatogram and calculated results illustrated the aging was consistent between building processes.

Figure 1. The RI(concentration) and RALS (light scattering signal 90°) chromatograms from the analysis of samples taken from three equivalent builds).[4]

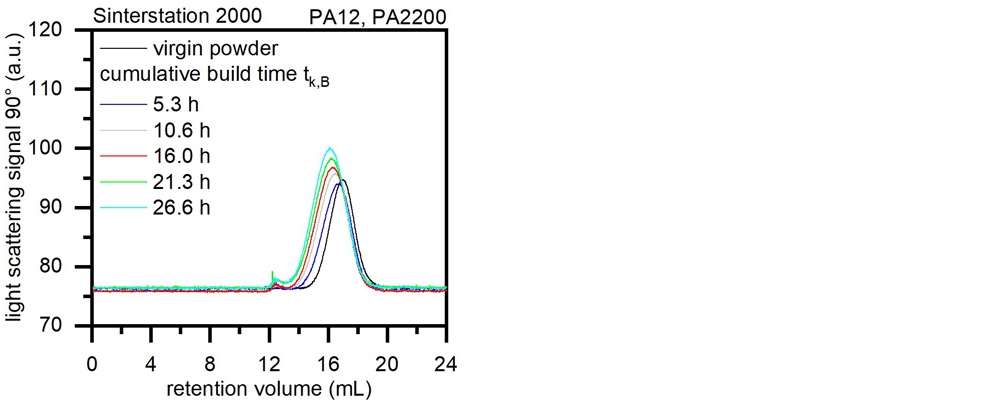

Figure 2 shows the chromatograms for samples measured after different cumulative build times and shows that the length of time the material is exposed to elevated temperatures has a direct influence on the growth of the PA12’s molecular weight. This is visualized by the polymer eluting at earlier retention volumes with increasing build time (figure 2).

Figure 2. Overlay of the RALS chromatograms produced from the analysis of samples from various cumulative build times (cumulative build time is the sum of the build time over a given number of build cycles, and hence the maximum length of time material has been exposed the build environment).[4]

The intensity of the light scattering signal is proportional to molecular weight. As such the light scattering detectors can detect low levels of high molecular weight material present in the samples, as seen in figure 2 eluting between 12 and 14 mL. In figure 2, this allowed for the detection of high molecular weight components at very low concentrations in the PA12 powder at the cumulative build times of 10.6, 16.0, 21.3 and 26.6 h.

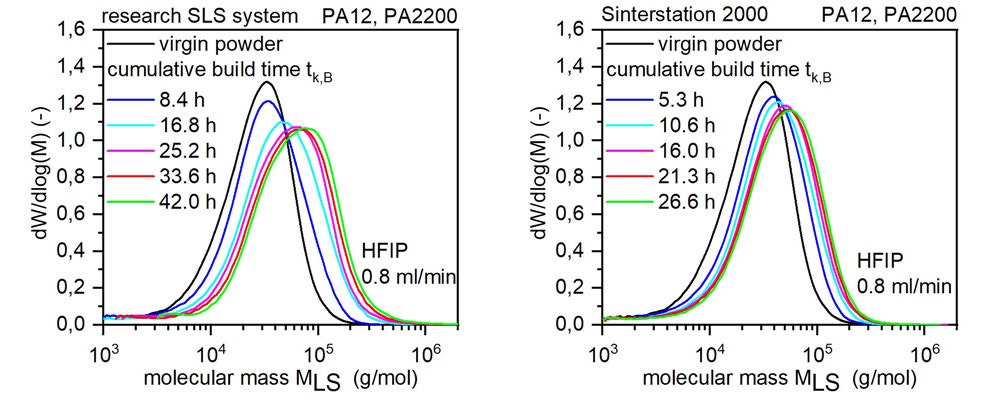

Processing the data shown in figure 2 as well as data acquired from the research SLS system at the FAU showed that in addition to the change in retention volume the molecular weight distribution also shifted toward the high molecular weight (figure 3).

Figure 3. Influence of the cumulative build time on the molecular weight distribution of polyamide 12. Left: Sinterstation 2000, Right: Research SLS system.[4]

The different effects of the two SLS systems become obvious, as each shift is greater in the research SLS system (figure 3). This is thought to be largely due to each build process being longer for the research SLS system. Between the systems, the molecular weight results correlate strongly to the cumulative build time rather than the number of cycles. In Table 1, the resulting weight average molecular weights, and dispersities (Mw/Mn) are shown. The dispersity fluctuates minimally between 2.2 and 2.6 with no correlation to build time, this range of values is not far from the theorized value for a polycondensation reaction (Schulz-Flory distribution (Mw/Mn = 2)).[4]

| SLS system | Temperature (°C) | Cumulative build time (h) | Average molecular weight MW (g/mol) | Mw/Mn |

|---|---|---|---|---|

| n/a | - | 0 | 32,900 | 2.2 |

| Sinterstation 2000 | 172 | 5.3 | 42,300 | 2.4 |

| 172 | 10.6 | 49,400 | 2.5 | |

| 172 | 16.0 | 53,700 | 2.5 | |

| 172 | 21.3 | 57,200 | 2.5 | |

| 172 | 26.6 | 61,100 | 2.3 | |

| Research SLS system | 172 | 8.4 | 49,700 | 2.2 |

| 172 | 16.8 | 58,600 | 2.6 | |

| 172 | 25.2 | 67,900 | 2.5 | |

| 172 | 33.6 | 77,000 | 2.4 | |

| 172 | 42.0 | 85,700 | 2.4 |

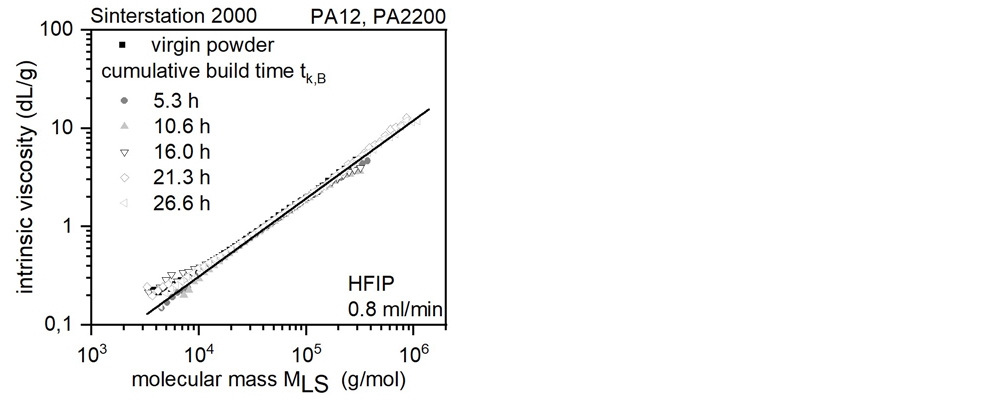

One of the true powers of the multi-detection GPC is to produce Mark-Houwink plots in a single measurement by combining the information from three detector types RI, light scattering and viscometer. The Mark-Houwink plot shows intrinsic viscosity (measured by the viscometer detector) as a function of molecular weight (measured by the light scattering detector). Through the Mark-Houwink plot, different structures can be easily identified. A study of figure 4 below reveals the mechanism of how the PA12 grows in molecular weight under the LS build environment. As each of the samples representing the various cumulative build times extends further to higher molecular weights, they remain along the same flat line illustrating that the polymer chains increase in molecular weight linearly. Constructing these Mark-Houwink plots proved crucial in proving the mechanism to be solid-state polycondensation.

Figure 4. Mark-Houwink structural plot for different cumulative build times.[4]

By analyzing the PA12 by triple detection GPC not only was Prof. Wudy able to illustrate the major influence of cumulative build time on the aging in terms of molecular weight increase but also using it to produce Mark-Houwink plots and show the growth was linear, not crosslinking or branching. Detailed information on the measurement methodology, on the powder preparation and on the building process layout as well as further results can be found in [Wudy, K., & Drummer, D. (2019). Aging effects of polyamide 12 in selective laser sintering: Molecular weight distribution and thermal properties. Additive Manufacturing, 25, 1-9]

[1] Schmid, Manfred. Selektives Lasersintern (SLS) mit Kunststoffen: Technologie, Prozesse und Werkstoffe. Carl Hanser Verlag GmbH Co KG, 2015.

[2] A. Wegner, C. Mielicki, T. Grimm, B. Gronhoff, G. Witt, J. Wortberg, Polym. Eng. Sci., 54 (2014), p. 1540

[3] K. Dotchev, W. Yusoff Rapid Prototyp. J., 15 (2009), p. 192

[4] Wudy, K., & Drummer, D. (2019). Aging effects of polyamide 12 in selective laser sintering: Molecular weight distribution and thermal properties. Additive Manufacturing, 25, 1-9