Homogenization

Effective homogenization process monitoring and control.

Effective homogenization process monitoring and control.

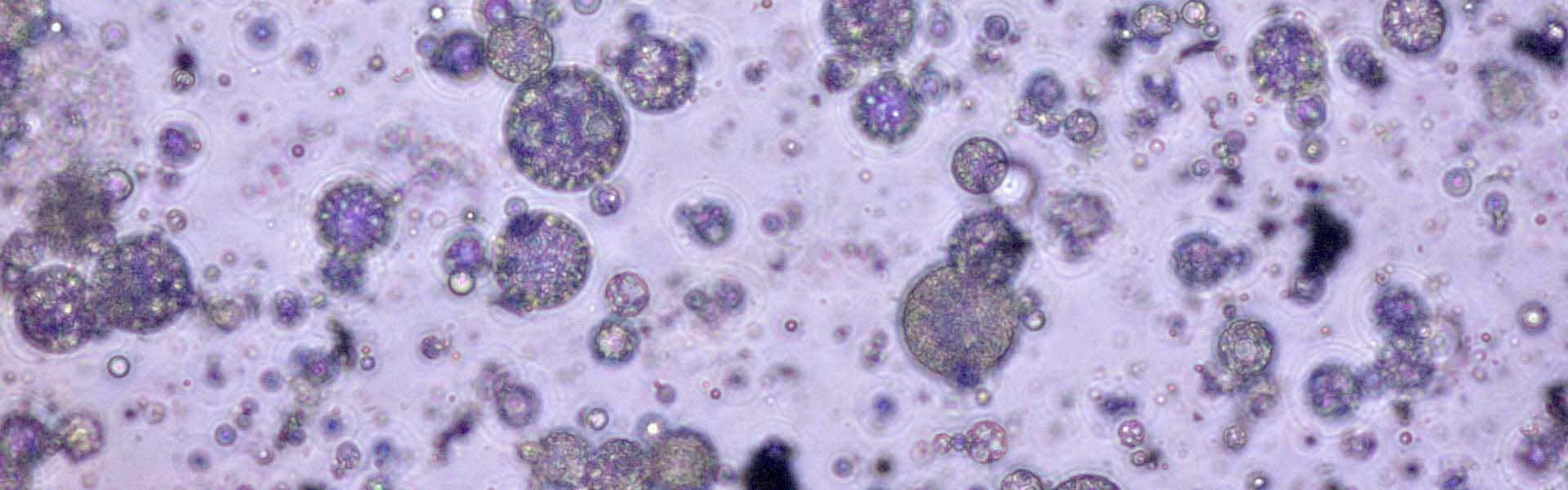

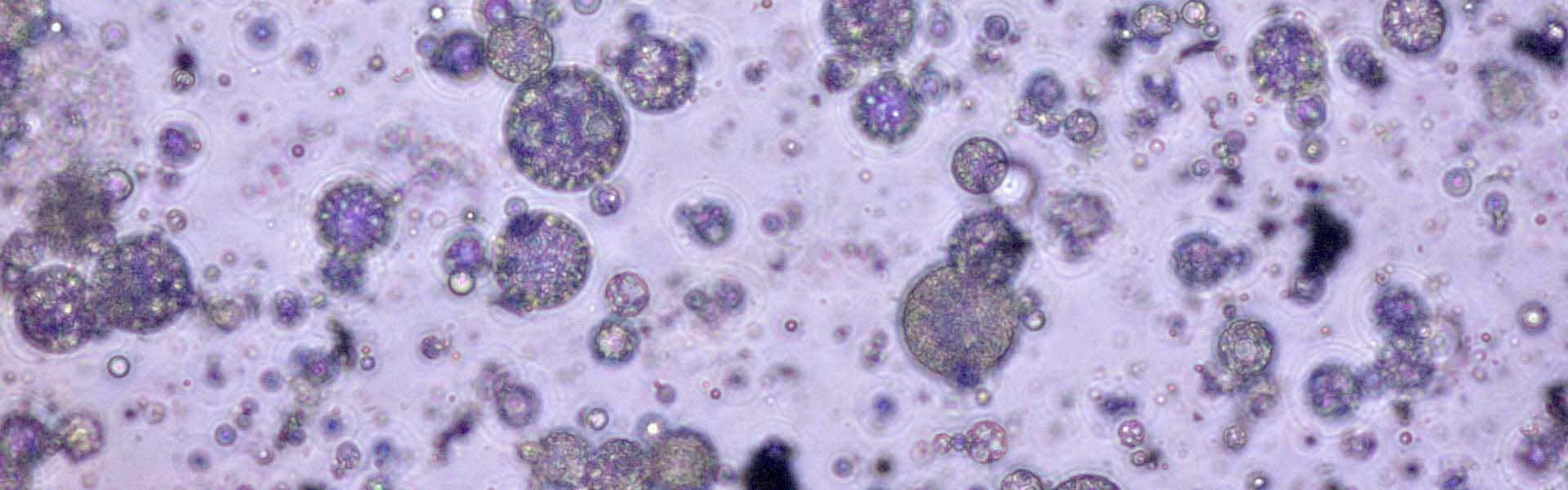

The efficient operation of homogenization and emulsification processes rely on continuous particle size analysis for:

Droplet size is a Critical Quality Attribute (CQA) in emulsion stability and dose content uniformity for pesticides and pharmaceuticals products.

In contrast, the droplet size of oil-in-water emulsions, in areas such as crude oil processing, influences the separation characteristics of these immiscible liquid mixtures and their behavior in hydrocyclones and other key unit operations.

Generally the finer the droplets, the more stable the emulsion. However, producing fine droplets is more energy-intensive. Tightly controlling droplet size, to a specification just fine enough to meet stability targets, is highly effective in minimizing energy consumption.

High shear homogenizers are often chosen for homogenization and emulsification applications. Whatever the equipment or process stream, Malvern Panalytical works with suppliers and customers to bring the process measurement technology expertise required to engineer truly optimal processing solutions.