X-ray fluorescence spectroscopy & XRF applications

X-ray fluorescence is an analytical technique that can be used to determine the chemical composition of a wide variety of sample types including solids, liquids, slurries and loose powders. XRF is also used to determine the thickness and composition of layers and coatings. It can analyze elements from beryllium (Be) to uranium (U) in concentration ranges from 100 wt% to sub-ppm levels.

XRF is an atomic emission method, similar in this respect to optical emission spectroscopy (OES), ICP and neutron activation analysis (gamma spectroscopy). Such methods measure the wavelength and intensity of ‘light’ (X-rays in this case) emitted by energized atoms in the sample.

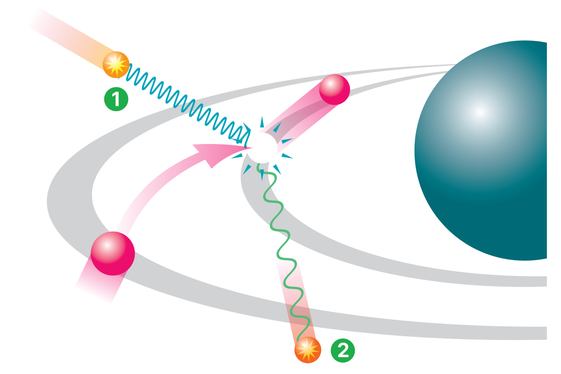

In XRF, irradiation by a primary X-ray beam from an X-ray tube causes the emission of fluorescent X-rays with discrete energies characteristic of the elements present in the sample.

Figure, right: Example of the X-Ray fluorescence (XRF) process: 1) Incoming photon 2) Characteristic photon.

XRF is a versatile analytical technique that finds application across an extensive spectrum of industries and scientific fields. Its adaptability and precision have made it an indispensable tool for understanding and manipulating the elemental composition of materials. From aiding in material identification and quality control in industries to preserving cultural heritage and advancing scientific research, XRF continues to play a pivotal role in enhancing our understanding of the elemental world.

XRF is widely used in quality and process control. Users can quickly get accurate and precise results with limited effort on sample preparation, and it can be readily automated for use in high-throughput industrial environments. XRF's precision and non-destructive nature make it an invaluable tool for quality control in various manufacturing sectors, such as:

XRF plays a pivotal role in materials research and development:

In the pharmaceutical and medical fields, XRF also has diverse applications:

![[Abstract polygonal space low poly dark background with connecting dots and lines. Connection structure.] shutterstock_384539449.jpg](https://dam.malvernpanalytical.com/915fb23a-bfbb-4bd8-ae5b-adea00c201c8/shutterstock_384539449_Original%20file.jpg)

From sample preparation to result reporting, we help you build up your ideal workflow to achieve your elemental analysis needs.

Malvern Panalytical instruments’ have driven XRF innovation in several areas. With the acquisition of SciAps in 2024, including their X-series handheld XRF analyzers and PowerHouse X benchtop systems, we are further enhancing our ability to offer cutting-edge solutions for elemental analysis in both laboratory and field environments. Elemental analysis instruments can be energy-intensive and generate significant waste, but eco-efficient innovation from Malvern Panalytical, including the portable, high-performance capabilities of the SciAps products, has the potential to change this.

We also believe that an instrument should not be complicated to use just because it is powerful, so we have invested in user-friendly features that make method development and data quality management a breeze. Whether in the lab or out in the field, with our XRF instruments you benefit from the optimum combination of technological advancement, thoughtful flexibility, and sustainable performance.

We offer a wide range of X-ray Fluorescence solutions and XRF analyzers for the analysis of elemental composition of a wide range of materials and applications, and comprising both wavelength and energy-dispersive solutions. With the addition of SciAps products, including the X-series and the PowerHouse X, we now provide portable, high-performance options that expand our offerings beyond traditional lab-based systems. These solutions bring advanced elemental analysis capabilities to the field, making them ideal for applications like metal sorting, mining exploration, and compliance screening.

For more information on XRF analyzer prices, read our 'how much does an XRF analyzer cost' page. Or discover our solution portfolio in the table below.

Speed or accuracy? There is often a dilemma with XRF spectrometers between quality data that is still usable and rapid results that are detailed enough. With our premium instruments, the trade-off between performance and speed disappears, thanks to innovative features and thoughtful design across our range.

We also offer innovative form factors for a variety of space requirements. Some of our portable and benchtop instruments have accuracy similar to floor-standing XRF instruments.

The XRF spectrometers of the past often struggled to keep up with the demands of an ambitious laboratory. Each sample method required extensive training, and the instruments often lacked the sample changer capacity for efficient measurement.

With our instruments, you can count on accurate results and high sample throughput, saving your lab valuable time. Fast feedback loops and a variety of monitoring features across our range further enhance your XRF efficiency by streamlining your workload and simplifying maintenance.

There are many ways to analyze elemental composition in quality control – ICP, AAS, and XRF, for example – and each technique has its advantages. But XRF has a particularly high number of advantages compared with other techniques.

Where alternative techniques often require destructive sampling for the analysis to work, XRF is fast and non-destructive. In addition, analysis can be done in air at the production site, and it’s typically more cost-effective than other techniques.

The technology used for the separation (dispersion), identification and intensity measurement of a sample’s X-ray fluorescence spectrum gives rise to two main types of spectrometer: wavelength dispersive (WDXRF) and energy dispersive (EDXRF) systems.

Find out more about these spectrometer types and the technologies behind them here:

We offer a wide range of X-ray Fluorescence solutions and XRF analyzers for the analysis of elemental composition of a wide range of materials and applications, and comprising both wavelength and energy-dispersive solutions.

For more information on XRF analyzer prices, read our how much does an XRF analyzer cost page. Or discover our solution portfolio in the table below.

Our range of XRF software packages can support you to extract the maximum value from your XRF instrumentation. Our commitment to excellence means that our software is continuously evolving. We invest in research and development to stay at the forefront of XRF analysis technology to ensure that you have access to the latest advancements and features.

RevontiumEnergy-dispersive XRF, designed for demanding labs. Economical footprint. 4x speed. No compromise on precision. |

ZetiumHigh end floor-standing WDXRF spectrometers |

Epsilon rangeEDXRF benchtop and on-line spectrometers |

Axios FASTHigh throughput simultaneous WDXRF spectrometer |

2830 ZTAdvanced semiconductor thin film metrology solution |

SciAps X-SeriesThe world’s lightest, smallest, fastest, high precision XRF analyzers |

|

|---|---|---|---|---|---|---|

| Measurement type | ||||||

| Thin film metrology | ||||||

| Elemental analysis | ||||||

| Contaminant detection and analysis | ||||||

| Elemental quantification | ||||||

| Chemical identification | ||||||

| Technology | ||||||

| Wavelength Dispersive X-ray Fluorescence (WDXRF) | ||||||

| Energy Dispersive X-ray Fluorescence (EDXRF) | ||||||

| Elemental range | Na-Am | Be-Am | F-Am | B-Am | B-Am | Mg-U |

| LLD | 0.1 ppm - 100% | 0.1 ppm - 100% | 1 ppm - 100% | 0.1 ppm - 100% | 0.1 ppm - 100% | |

| Resolution (Mn-Ka) | 145 eV | 35eV | 145eV | 35eV | 35eV | 140 eV |

| Sample throughput | Up to 200per 8h day | Up to - 240per 8h day | Up to - 160per 8h day | Up to 480 | up to 25 wafers per hour | |