The removal of Natural Organic Matter (NOM) via coagulation and sedimentation processes is an essential initial step in water treatment, but one that is challenging for water utilities across the world. Recent trials at Severn Trent’s Tittesworth Water Treatment Works (WTW), a 40 Mld plant located in Leek (Staffordshire, UK) have demonstrated the ability of online zeta potential measurements to provide a reliable lead measure for monitoring and controlling clarification performance and to support a new approach to coagulation optimization. Evidence suggests that the technology and approach works well irrespective of water source or clarification system, providing that NOM removal is being affected via charge neutralization.

Adopting zeta potential as the lead measure of performance is straight-forward and generates easy to understand data that can be used to reduce water quality risk, decrease chemical usage costs and improve operating efficiency. Furthermore, experience indicates that online zeta potential measurement will provide a secure platform for fully automated process control – a long term industry goal.

Authors: Emma Sharp (Water Treatment and Quality Lead)1; Joanne Claronino (Senior Process Engineer)1; Kieron Maher (Innovation Manager Technical Team)1 Alon Vaisman (Product Development Manager, Process Systems)2

1Severn Trent Water, 2Malvern Instruments

Severn Trent, a leading UK water company, has been investigating the ability of zeta potential measurements to enhance coagulation control for close to a decade. This white paper looks how the company is using the Zetasizer Nano, off- and online, to reduce operational risk and coagulant costs, and establish a robust platform for automated clarification control.

The removal of Natural Organic Matter (NOM) via coagulation and sedimentation processes is an essential initial step in water treatment, but one that is challenging for water utilities across the world. Recent trials at Severn Trent’s Tittesworth Water Treatment Works (WTW), a 40 Mld plant located in Leek (Staffordshire, UK) have demonstrated the ability of online zeta potential measurements to provide a reliable lead measure for monitoring and controlling clarification performance and to support a new approach to coagulation optimization. Evidence suggests that the technology and approach works well irrespective of water source or clarification system, providing that NOM removal is being affected via charge neutralization.

Adopting zeta potential as the lead measure of performance is straight-forward and generates easy to understand data that can be used to reduce water quality risk, decrease chemical usage costs and improve operating efficiency. Furthermore, experience indicates that online zeta potential measurement will provide a secure platform for fully automated process control – a long term industry goal.

The removal of NOM is one of the main challenges facing water utilities in both the UK and the US. Changes in land management practice and increased carbon loss from solids (potentially attributable to climate change) mean that a greater amount of accumulated organics is now routinely flushed into the aquatic environment during increased surface run-off events such as snowmelt or heavy rainfall. NOM removal is traditionally promoted using trivalent coagulants to encourage the formation of flocculated material and aid separation. This has long proven a successful strategy but operational problems are now being reported during periods of elevated organic levels in the water. Such problems include the formation of fragile flocs, increased particulate carryover onto downstream processes and increased disinfection by-product (DBP) formation, as a direct result of inadequate NOM removal [1,2].

Like many WTWs, Tittesworth physically removes NOM by conventional coagulation, utilizing positively charged ferric salts to neutralize the negative charge on the NOM and promote flocculation. The resulting flocs are separated by dissolved air flotation. Operational goals associated with the efficient removal of NOM in this step of the process are to:

Severn Trent has historically used jar tests, a traditional industry technique, to monitor flocculation performance at its WTWs across the UK. The jar test is a manual procedure that can take up to 30 minutes to perform depending on the method adopted. It involves dosing an extracted water sample with a concentration of coagulant and then assessing floc formation, under standard conditions. This analysis provides a relative indication of plant performance but is highly subjective, and associated with a significant time delay – between sample taking and receipt of results. Furthermore, practicalities dictate that jar testing is not carried out sufficiently often to detect rapid changes in raw water quality and the technique offers little information about how to change chemical addition to optimize the coagulation process following a poor result. Jar testing is also limited in terms of how closely it mimics true process conditions, which can inhibit the relevance of the resulting data.

The time taken to make measurements and the inherent variability of the data mean that use of the jar test tends to be associated with relatively coarse indication of process performance. This uncertainty leads to a tendency to overdose, “to err on the side of caution” with the hope of maintaining stable operation, in the event of a sudden change in water composition. Considering the cost of flocculants this approach is unsatisfactory and, in fact, overdosing can reverse the surface charge, building a cationic charge on the particle surface that re-stabilizes contaminants in the water. As a leader in the industry, Severn Trent began to investigate replacement analyses for the jar test a number of years ago, with the aim of identifying a more informative and reliable technique, that ultimately would provide a more secure foundation for plant control and future automation.

Introducing zeta potential: a reliable indicator of dispersion stabilityMeasurements of zeta potential are commonly used to assess the stability of a wide variety of colloidal systems. Zeta potential is a measure of the magnitude of electrostatic or charge repulsion at the boundary layer surrounding a particle and is one of the fundamental parameters known to affect a system’s stability. Two layers of ions surround particles within a solution, the tightly bound inner Stern layer and the outer diffuse layer, where ions are less firmly associated. Within the diffuse layer there is a notional boundary called the slipping plane beyond which the particle exerts little influence. Charge at the slipping plane is referred to as the zeta potential.

Zeta potential therefore quantifies the balance of repulsive and attractive forces that the particles experience as they approach one another. At a zeta potential near to zero, these forces are low and the system is unstable, highly prone to aggregation. A pronounced negative or positive zeta potential (+/-30 mV), on the other hand, is indicative of an electrostatically stable system that will resist particle aggregation. |

Severn Trent’s evaluation of zeta potential as a metric for clarification control began in 2007 with a series of bench-scale experiments. These were conducted to rigorously investigate the link between clarified water quality, as quantified by turbidity measurements, and zeta potential, and included repeated analyses of water derived from a number of geographies. This work suggested a universal relationship between zeta potential and clarification performance that held for all water sources. Zeta potentials in the range -10 mV to + 3mV were consistently associated with good performance in the charge neutralization process suggesting that controlling zeta potential in this range would ensure effective operation. This can be achieved either by altering coagulant dosage levels or by modifying pH, which affects the charge on the coagulant, and consequently its impact.

This early work also demonstrated the attractive practicalities of performing zeta potential measurements using a laser based technology. The advanced, automated analytical system deployed for zeta potential measurement (Zetasizer Nano, Malvern Instruments), delivers accurate results, consistent from operator to operator, in under 5 minutes.

In summary it was therefore concluded that Zeta potential measurement offered the opportunity to improve plant control by developing clear operational guidelines based on information provided by timely, user independent measurements.

Introducing the Zetasizer WT: a plant solution for online zeta potential measurementThe Zetasizer WT combines Malvern’s industry leading electrophoretic light scattering technology with two decades of expertise with in-process measurements to deliver a dedicated online zeta potential analyzer for water treatment plants. The result is a fully automated system that enables highly reliable zeta potential measurements for the efficient monitoring and control of flocculation processes.

Zeta potential is measured using the technique of ELS. An electric field is applied across a sample and particles migrate towards the electrode of opposite charge at a velocity proportional to the magnitude of their zeta potential. The velocity at which the particle moves is measured using the technique of laser Doppler anemometry. The frequency shift, or phase shift, of an incident laser beam caused by the moving particles is measured to determine particle mobility. This is converted into zeta potential values, using the known viscosity of the dispersant, by applying Smoluchowski or Huckle theories [3]. |

In 2009, following a successful trial at Bamford WTW, Tittesworth WTW began to use zeta potential measurements of the coagulant dosed water entering the flocculator to control the process.

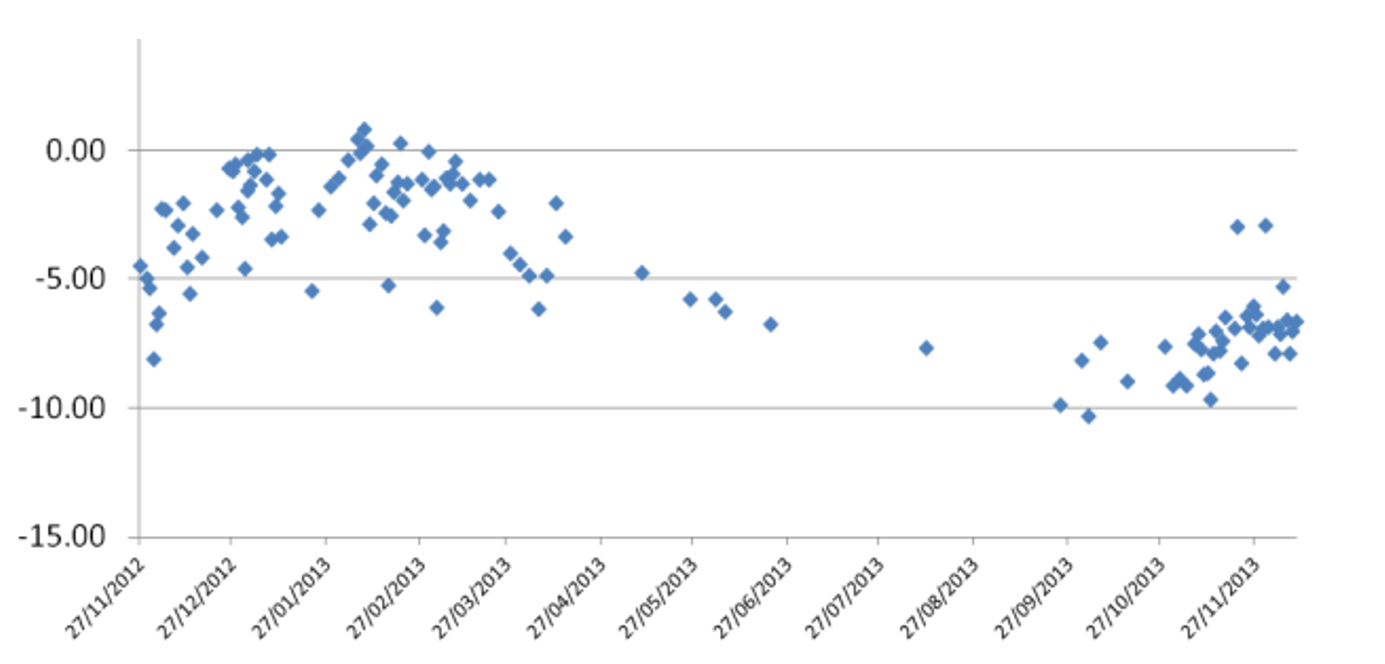

Figure 1: Early trials with zeta potential measurement highlighted opportunities for both chemical savings and risk reduction

This trial demonstrated clearly that monitoring and responding to zeta potential measurements offered a significant opportunity to improve process operation. At certain times in the trial (see figure 1) the zeta potential of the dosed water was close to the +3mV boundary of the preferred operating range suggesting excessive charge neutralization, the addition of more positively charged coagulant than actually required. Here, then there was opportunity to reduce chemical costs.

On the other hand, at other periods, zeta potential drifted close to the -10 mV boundary of acceptability. This indicated that coagulant addition rates had drifted too low for the current water quality, leaving the plant vulnerable to a further change in raw water properties that could swing operation out of the preferred range. At these times higher coagulant dosage levels would provide a more secure buffer against further changes in raw water quality, thereby reducing risk.

This trial clearly demonstrated the ability of zeta potential to provide a lead measure for clarification control; however, at this point in time measurements were still conducted in the lab. Moving zeta potential measurements online was the next logical step.

Building on established expertise for implementing analytical techniques within the process environment Malvern revealed the first online Zetasizer Nano in 2010, demonstrating its robustness and reliability via collaborative trials at Aurora Water in the US [4]. The results confirmed that online zeta potential analysis could offer further improvements, over lab-based measurement, in terms of rapid, real time data acquisition and the ability to detect and alarm process changes, while at the same time reducing reliance on manual analysis.

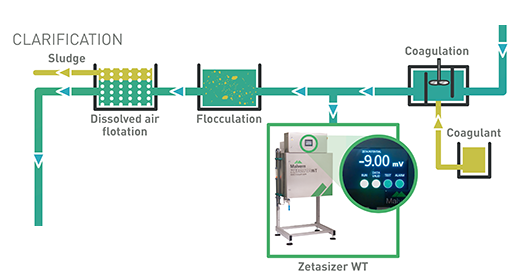

A Zetasizer WT was installed in Tittesworth in 2014, integrating the fully automated online analyzer and dedicated sampling system into the water purification process as shown in Figure 3. Water from the inlet to the flocculator is pumped into the sampling loop of the analyzer at a controlled flow rate and directed to a header tank, which ensures a constant supply of sample. The sampling system was optimized as part of the plant trial to maximize robustness while at the same time reducing maintenance requirements. Samples are drawn in for analysis at a user specified frequency and results are sent directly to the SCADA plant control system. Post measurement, samples are disposed of to open waste. The inclusion of a mixing area between coagulant injection and sample source ensures that a well-mixed, representative sample is fed to the analyzer, which is essential for the measurement of relevant data.

Figure 3: Integration of online Zeta Potential analyser into the water purification system

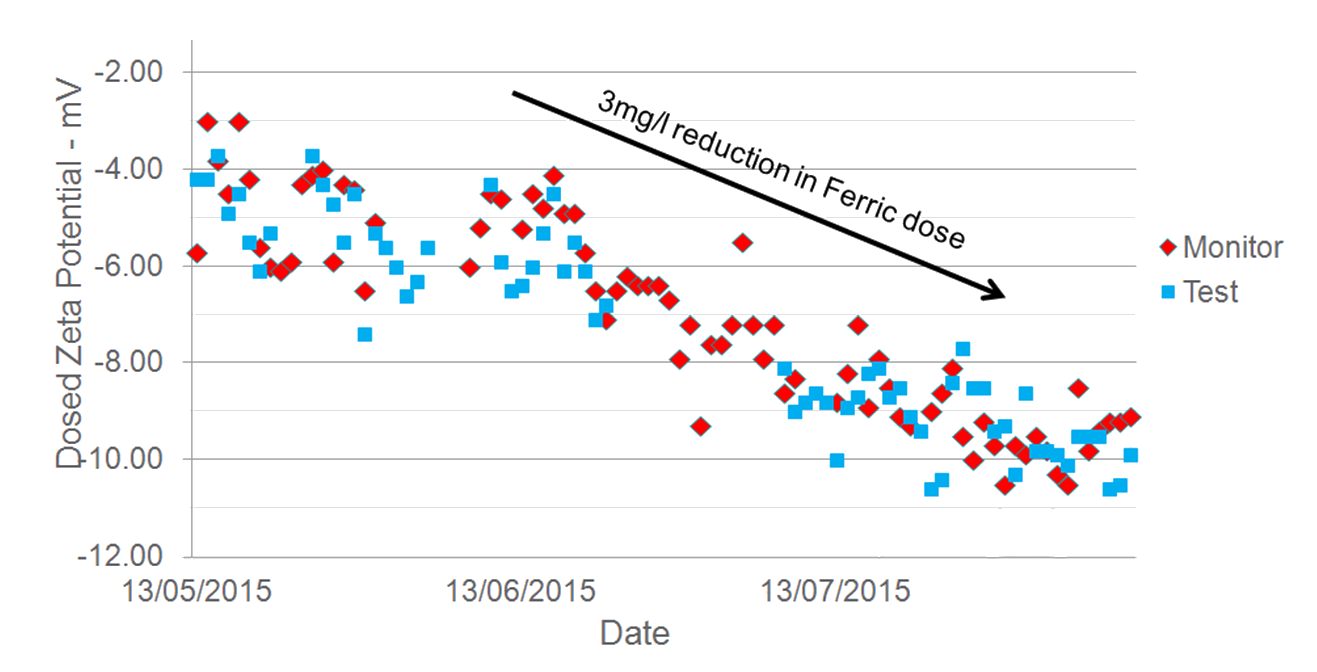

Online implementation reduces the risk of sampling errors and measurement variability, while at the same time making it practical to measure at a much higher frequency. Tittesworth continued to run the laboratory-based Zetasizer Nano system in tandem throughout the trial to compare off- and online data. Figure 4 demonstrates the ability of the online solution to deliver continuous zeta potential measurements to the same precision as lab analyses over a prolonged period of operation confirming the effectiveness of the online system.

As the trial progressed confidence in the online analyzer and the associated control strategy grew to the extent that over the three month trial the operational team were able to push closer to the boundaries of acceptable operation defined by zeta potential values and steadily reduce the amount of coagulant used (see figure 4). Running at increasingly negative zeta potentials, down to around -10 mV, has delivered a reduction of 3mg/L Fe in dosage levels, a saving of around 20%, with no impact on plant performance.

Figure 4: The accuracy and frequency of online measurement (Monitor – red) provides the confidence to optimize/reduce coagulant dosage. Lab data – Test – is shown in blue

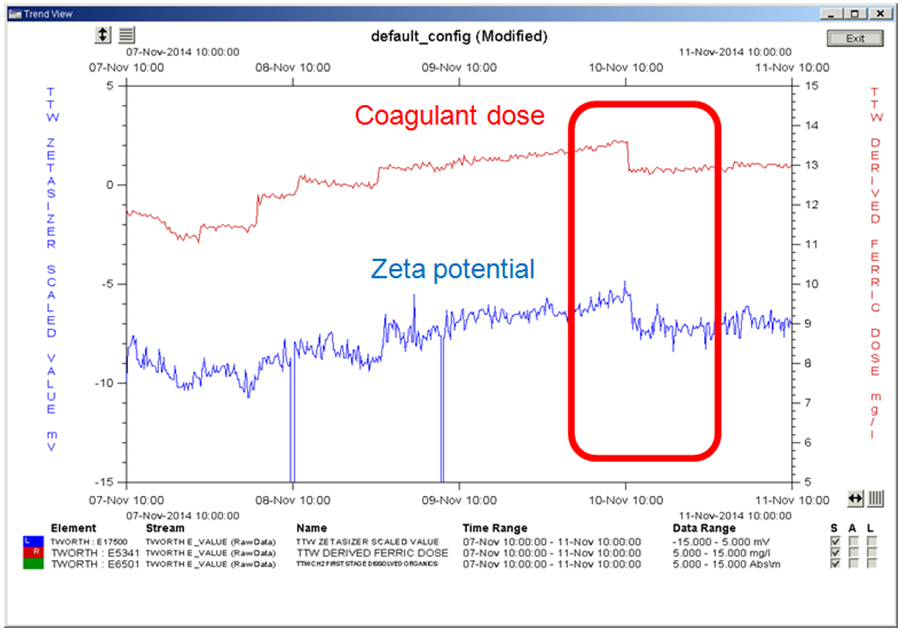

The online analyzer has been enthusiastically received by plant operators because of its ability to provide a reliable indicator of process performance that is not influenced by changes in water chemistry. They now control the plant with reference to a clear set of guidelines, allowing informed, balanced decision making, which can be supported remotely, if necessary, as a result of easy access to the relevant data. The trend data accessible via the SCADA system is particularly valuable for troubleshooting, as is the ability to configure alarms to ensure any issues are detected and resolved prior to impacting downstream performance. These features make online measurement considerably more informative than offline analysis, the frequency of measurement giving a sharp response which is easily linked to process changes, intentional or otherwise. For example, figure 5 shows zeta potential closely tracking coagulant dosage during a trial period, and the marked shift in zeta potential triggered by a decrease in chemical dosage rate (highlighted by the red ring).

Figure 5: Zeta potential measurements responsively track the impact of changes in coagulant dosage providing a secure basis for clarification control

Severn Trent’s extensive trials of zeta potential have securely established its ability to enhance coagulation control, and there are now plans to install more Zetasizer WT units at a number of upland source water WTW that, like Tittesworth, deploy charge neutralization processes for NOM removal.

A defining benefit of using zeta potential for coagulation monitoring is that measurements are independent of water chemistry and provide a reliable indication of plant performance that can be used to develop clear and precise guidelines for control. Online measurements have been shown to be in close agreement with lab-generated data but offer the major advantages of continuous monitoring, trend data (remotely accessible if required) and associated alarms, and minimal manual input. These features support a swift and effective response to changing plant conditions, such as fluctuations in raw water quality, reducing the risk of an excursion in water quality or downstream operational issues. This is particualrly important as the levels of NOM in raw water rise.

At Tittesworth WTW the confidence engendered by operation with online zeta potential measurements has led to a reduction in coagulant usage of around 20%. This is in close agreement with savings made by other users of the technology [4] and suggests that payback times for its implementation are likely to be in the order of two years, depending on baseline performance. However, reducing chemical usage has additional benefits, particularly as the demand for, and price of, Ferric based coagulants increases due to tighter phosphorous consents in wastewater. Using less chemicals also has the added benefit of reducing the volume of wastewater and sludge to be treated.

These trials suggest that over the longer term online zeta potential measurement holds promise for more complete automation of the clarification step. The guidelines for optimizing coagulation conditions based on zeta potential readings are so clear and concise that they could be relatively easily developed into algorithms for continuous automated control. A fully automated, universally applicable, coagulant control system that works irrespective of water source, for all systems operating charge neutralisation, and that does not require recalibration when source water conditions change, now appears to be in reach. This would transform operating practice within the water industry enabling smarter, more efficient operation and the more robust control of risk.

[1] E. Sharp et al. ‘Seasonal variations in natural organic matter and its impact on coagulation in water treatment’ Science of the Total Environment, Vol 363, Issues 1 – 3, June 2006 pp183 – 194.

[2] E. Sharp et al. ‘Impact of fractional character on the coagulation of NOM’ Colloids and Surfaces A Physicochem. Eng. Aspects, 286 (2006) 104-111

[3] Zeta potential in 30 minutes – Malvern Instruments technical note

[4] B. Fulbright et al. ‘How good is online zeta potential measurement in water treatment?’, Water/Waste Processing magazine, August 2014