LN2 Transfer System

Specifically developed for conveniently filling Dewars for gas adsorption instruments, but also can be used for other cryogen applications.

Looking for more information?

To request a quote, more information or download a brochure select an option below.

A powerful combination: Micromeritics is a Malvern Panalytical company

Surface area and porosity are important physical properties that influence the quality and utility of many materials and products. Therefore it is critical that these characteristics be accurately determined and controlled. Similarly, knowledge of surface area and especially porosity are important properties in understanding the formation, structure, and potential application of many natural materials.

The automated Micromeritics ASAP 2425 surface area and porosimetry system is designed to help busy laboratories expand their workflow while providing highly accurate and precise surface area and porosimetry data. High performance, versatile analysis, and sample preparation systems are included in the same instrument.

The Micromeritics ASAP 2460 surface area and porosimetry analyzer incorporates a unique expandable system designed for high performance and high sample throughput. The base ASAP 2460 is a two-port master control unit. For more throughput, additional two-port auxiliary units can be connected to the master unit expanding the system to either a four-port or six-port analyzer.

The automated Micromeritics ASAP 2425 surface area and porosimetry system is designed to help busy laboratories expand their workflow while providing highly accurate and precise surface area and porosimetry data. High performance, versatile analysis, and sample preparation systems are included in the same instrument.

Six independent analysis stations

Sample tube with Isothermal Jacket

Long-life Dewars

Po tube with Isothermal Jacket provides continuous Po reading

Twelve degassing stations

Independently controlled heating mantles

Surface area and porosity play major roles in the purification, processing, blending, tableting, and packaging of pharmaceutical products as well as their useful shelf life, dissolution rate, and bioavailability.

Surface area and porosity affect the curing and bonding of greenware and influence strength, texture, appearance, and density of finished goods. The surface area of glazes and glass frits affects shrinkage, crazing, and crawling.

Knowledge of surface area, total pore volume, and pore size distribution is important for quality control of industrial adsorbents and in the development of separation processes. Surface area and porosity characteristics affect the selectivity of an adsorbent.

Surface area and porosity must be optimized within narrow ranges to accomplish gasoline vapor recovery in automobiles, solvent recovery in painting operations, or pollution controls in waste-water management.

The wear lifetime, traction, and performance of tires are related to the surface area of carbon blacks used in their production.

The active surface area and pore structure of catalysts influence production rates. Limiting the pore size allows only molecules of desired sizes to enter and exit, creating a selective catalyst that will produce primarily the desired product.

The surface area of a pigment or filler influences the gloss, texture, color, color saturation, brightness, solids content, and film adhesion properties. The porosity of a print media coating is important in offset printing where it affects blistering, ink receptivity, and ink holdout.

The burn rate of propellants is a function of surface area. Too high a rate can be dangerous; too low a rate can cause malfunction and inaccuracy.

Controlling the porosity of artificial bone allows it to imitate real bone that the body will accept and allow tissue to be grown around it.

By selecting high surface area material with carefully designed pore networks, manufacturers of super-capacitors can minimize the use of costly raw materials while providing more exposed surface area for storage of charge.

Surface area is often used by cosmetic manufacturers as a predictor of particle size when agglomeration tendencies of the fine powders make analysis with a particle-sizing instrument difficult.

Surface area and porosity of heat shields and insulating materials affect weight and function.

Porosity is important in groundwater hydrology and petroleum exploration because it relates to the quantity of fluid that a structure can contain as well as how much effort will be required to extract it.

Nanotube surface area and microporosity are used to predict the capacity of a material to store hydrogen.

Fuel cell electrodes require high surface area with controlled porosity to produce optimum power density.

| Voltage | 100/115/230 VAC (± 10%) |

|---|---|

| Frequency | 50 or 60 Hz |

| Power | 800 VA, exclusive of vacuum pumps, which are powered separately |

| Temperature | 10 to 30 °C operating,

-10 to 55 °C storage or shipping |

|---|---|

| Humidity | Up to 90% relative (non-condensing) for instrument |

| Analysis | ASAP 2425: 6 sample ports, each with a constantly monitored saturation pressure port

ASAP 2460: 2, 4, or 6 sample ports (for krypton analysis, one sample port is used for dosing), each with a constantly monitored saturation pressure port |

|---|---|

| Degas | ASAP 2425: 12 degas ports, each with independently controlled heating mantle

ASAP 2460: N/A |

| Manifold temperature transducer | Type: Platinum resistance device (RTD) Accuracy: ±0.10 °C by keyboard entry Stability: ±0.10 °C per month |

|---|---|

| Manifold pressure transducer | ASAP 2425

Range: Vacuum to 950 mmHg Operating: 1000 mmHg maximum 10 mmHg added for krypton option, 1 mmHg for micropore option

Resolution:

1000 mmHg Transducer: 0.01 mmHg

10 mmHg Transducer: 0.0001 mm

1 mmHg Transducer: 0.00001 mmAccuracy:

1000 mmHg Transducer: within 0.1% FS

10 mmHg Transducer1: within 0.15% of reading

1 mmHg Transducer2: within within 0.12% of reading

ASAP 2460 Range: 0 to 950 mmHg

Operating: 1000 mmHg maximum 0 to 10 mmHg added for Krypton option

Resolution:

1000-mmHg Transducer: 0.001 mmHg 10-mmHg Transducer1: 0.00001 mmHg

1-mmHg Transducer**: 0.000001 mmHg

Accuracy: 1000-mmHg Transducer: within 0.15% of reading

10-mmHg Transducer1: within 0.15% of reading

1-mmHg Transducer2: within 0.12% of reading

|

| Sample and Po port transducers | Range: 0 to 950 mmHg

Resolution: 0.01 mmHg Accuracy: ±0.1% Full Scale |

| Vacuum control | Type: Thermocouple

Range: 0.001 to 1 mmHg |

| Dimensions (W, D, H) | ASAP 2425: 103 x 51 x 159 cm

ASAP 2460: 38 x 59 x 94 cm |

|---|---|

| Weight | ASAP 2425: 160 kg

ASAP 2460: 54 kg |

| Nitrogen unit | ASAP 2425: 2 oil-based pumps: 1 analysis, 1 degas. 4 pumps (optional): 2 oil-free (1 analysis, 1 degas), 2 high vacuum (1 analysis, 1 degas)

ASAP 2460: Nitrogen: Oil-sealed pump |

|---|---|

| Krypton Unit | ASAP 2425: Oil-based mechanical pump: 5 x 10-3 mmHg ultimate vacuum. Oil-free and high vacuum pump: 3.8 x 10-9 mmHg ultimate vacuum

ASAP 2460: Krypton & enhanced micropore option: High-vacuum pump |

| Capacity | ASAP 2425: 12 degas ports

ASAP 2460: N/A |

|---|---|

| Vacuum control | ASAP 2425: Selectable target pressure controls switchover from restricted to unrestricted evacuation

ASAP 2460: N/A |

| Evacuation rate | ASAP 2425: Selectable evacuation rate from 1.0 to 50.0 mmHg/s

ASAP 2460: N/A |

| Manifold pressure transducer | ASAP 2425:

Range: 0 to 950 mmHg

Resolution: 0.01 mmHg

Accuracy: ±0.1% Full Scale

ASAP 2460: N/A |

| Vacuum transducer | ASAP 2425:

Type: Thermocouple Range: 0.001 to 1 mmHg

ASAP 2460: N/A |

| Titled backfill gas | ASAP 2425: User-selectable at dedicated port, typically nitrogen or helium

ASAP 2460: N/A |

| Temperature control range | ASAP 2425:

Temperature Range: Ambient to 450 °C (Programmable)

Temperature Control: 1 ramp during evacuation phase, 5 additional selectable ramps during heating phase

Selection: Digitally set, 1 °C increments from computer

Accuracy: Deviation less than ±10 °C of set point at the sensing thermocouple embedded in the heating mantle

ASAP 2460: N/A |

Specifically developed for conveniently filling Dewars for gas adsorption instruments, but also can be used for other cryogen applications.

The Micromeritics FlowPrep lets you choose the most suitable gas, temperature, and flow rate for your application and sample material.

The Micromeritics VacPrep features six degassing stations, and a choice of vacuum or gas flow preparation on each of the six stations.

The Micromeritics MicroPrep features a high-quality digital control unit to regulate the heating mantle to the desired set point temperature.

The ASAP 2425 system includes twelve automatically controlled sample preparation ports that operate independently. Samples may be added or removed from degas ports without disturbing the treatment of other samples undergoing preparation.

The sample preparation system is fully automated with controlled heating time profiles. Temperature and ramp rate can be set and monitored individually and controlled from a few degrees above ambient to 450 °C. The temperature hold period may extend past the point when evacuation is completed.

A programmable pressure threshold can suspend the temperature ramp if the outgassing pressure exceeds the limit specified, preventing destructive steaming or other undesired reactions with residual gasses and vapors.

In addition to the standard ASAP 2425 and ASAP 2460, low surface area krypton and micropore models are available.

Low surface area (krypton) model includes the addition of a 10 mmHg transducer and permits accurate measurement of very low surface area materials (< 1 m2 /g).

The micropore model includes the addition of a 1 mmHg transducer which extends the low pressure measurement capabilities and allows enhanced performance for characterizing microporous materials. The transducer also increases pressure resolution in the range necessary for micropore analysis.

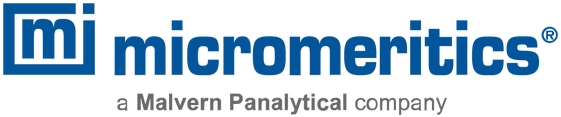

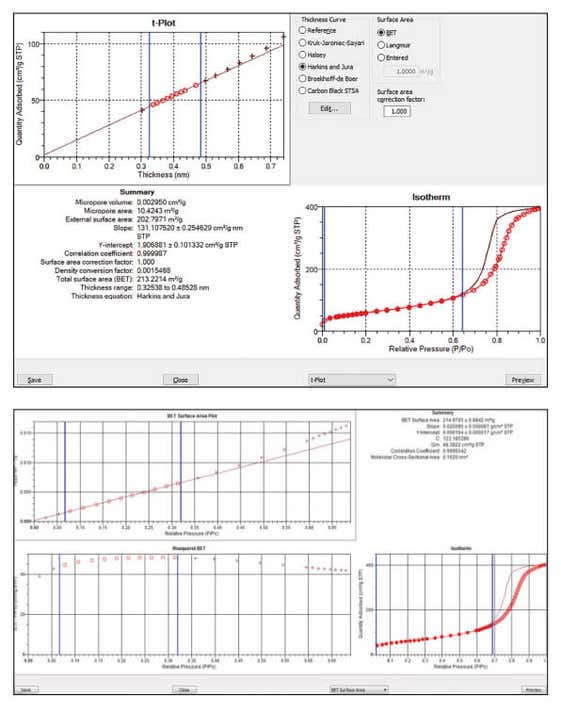

Innovative MicroActive Software

Micromeritics’ innovative MicroActive software allows users to interactively evaluate isotherm data.

Users can easily include or exclude data, fitting the desired range of experimentally acquired data points using interactive, movable calculation bars.

Isotherms can be viewed on either a linear or logarithmic scale.

When appropriate to the analysis performed, Interactive Reports include:

Version number:

Please contact support for the latest software version.

Combining porosimetry and surface area analysis, the ASAP 2425 and 2560 are the ideal match for high capacity requirements.