Borate fluxes and chemicals

Your first choice to fuse samples for XRF, ICP and AA analysis

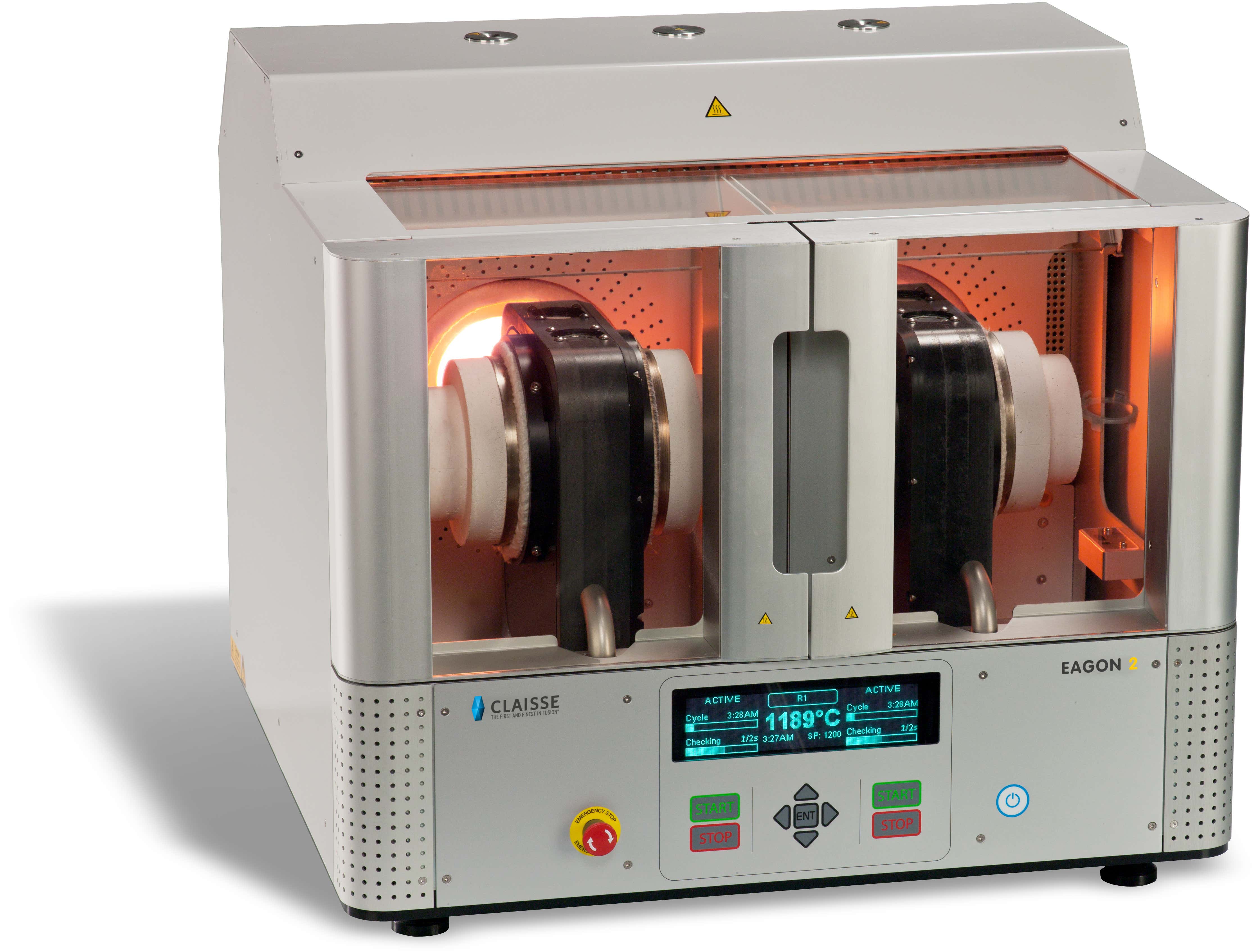

As the one-stop shop in fusion and the world leader in the production of borate fluxes, Claisse develops high-quality chemicals that are easy to use and that ensure no contamination.

Offered in two grades of purity (pure 99.98+% and ultra pure 99.995+%) and available with or without non-wetting agents, our lithium borate fluxes are homogeneous and available in bead format.

Use Claisse lithium borate fluxes to:

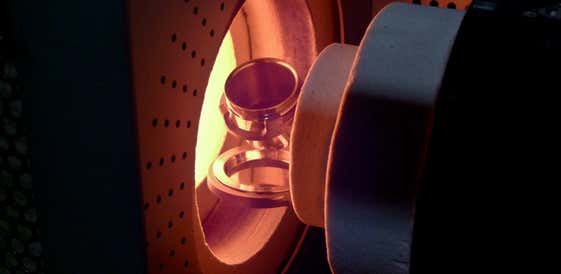

- Avoid crystallization

- Reduce the incidence of glass sticking to the platinumware

- Avoid cracking

Make your life easier, try our pre-weighed or customized borate fluxes.