Overview

The funnel sample feeder enables bulk samples of up to 15g to be loaded directly into the Aero S and Aero M dispersion units, enabling quick and consistent measurements of bulk powders to be achieved using the Mastersizer laser diffraction particle size analyzers as part of routine product quality control testing.

- Simple, effective sample preparation for bulk powder samples

- Decreased time-to-results, supporting routine QC operations

- Analysis of large sample masses, ensuring good sampling and reproducible measurements

- Software verification of the sample feed and dispersion settings aids method standardization and control

- Typical applications include the measurement of large, free flowing materials, such as coffee, as well as cohesive samples, such as calcium carbonate.

How it works

When measuring the particle size and size distribution of bulk materials, dry powder dispersion is advantageous as it enables the analysis of a large mass of powder. This helps when sampling materials which are polydisperse, improving result reproducibility and assisting detection of out-of-specification materials.

The Aero S and Aero M units disperse dry samples by accelerating particles through a venturi using compressed air. Dispersion efficiency is controlled by the changing the applied air pressure and the sample feed rate.

Mechanisms of dry powder dispersion

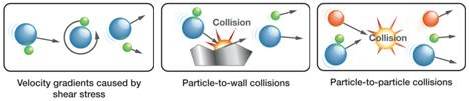

Dry powder dispersion is achieved through the shearing of agglomerates as well as by particle-particle collisions and particle-wall collisions. This ensures that agglomerated materials are dispersed to a primary particle size prior to measurement using the Mastersizer 3000 or Mastersizer 3000E laser diffraction particle size analysis system. The energy associated with each dispersion mechanism is user-controlled by setting the air pressure drop across the venturi, enabling dispersion to be achieved without particle break-up.

Management of the sample feed rate into the venturi is required to ensure that reproducible dispersion is achieved. The funnel sample feeder includes a vibrating tray which directs the flow of the powder sample into the venturi. Control of the vibration amplitude, coupled with adjustments to the funnel feeder configuration, enables reproducible sample flow to be achieved, even for polydisperse or cohesive materials.

Specification

| Size range | 0.1 - 3500µm*† |

|---|---|

| Maximum sample mass measured | 15g* |

| Dispersion pressure range | 0 - 4 bar |

| Pressure setting precision | +/- 0.1 bar |

| Pressure setting accuracy | +/- 0.03 bar |

| Feed rate range | 0 - 58ms-2 (expressed as 0-100%) |

| Feed rate precision | 2% FS |

| Materials in contact with sample | 316 stainless

|

| Maximum particle size | 3500 µm† |

| Minimum time between measurements | less than 60 sec * |

| Dimensions (W, D, H) | 180mm x 260mm x 380mm |

| Weight | 10.5kg |

| Power Supply | Supplied via the Mastersizer optical unit |

| Notes | * Sample dependent.

† Relates to the use of the unit with the Mastersizer 3000. Upper particle size limit is 1000µm when used with the Aero M on the Mastersizer 3000E. Note: Magnetic materials cannot be measured using the funnel sample feeder as the feeder includes magnetic components |