概要

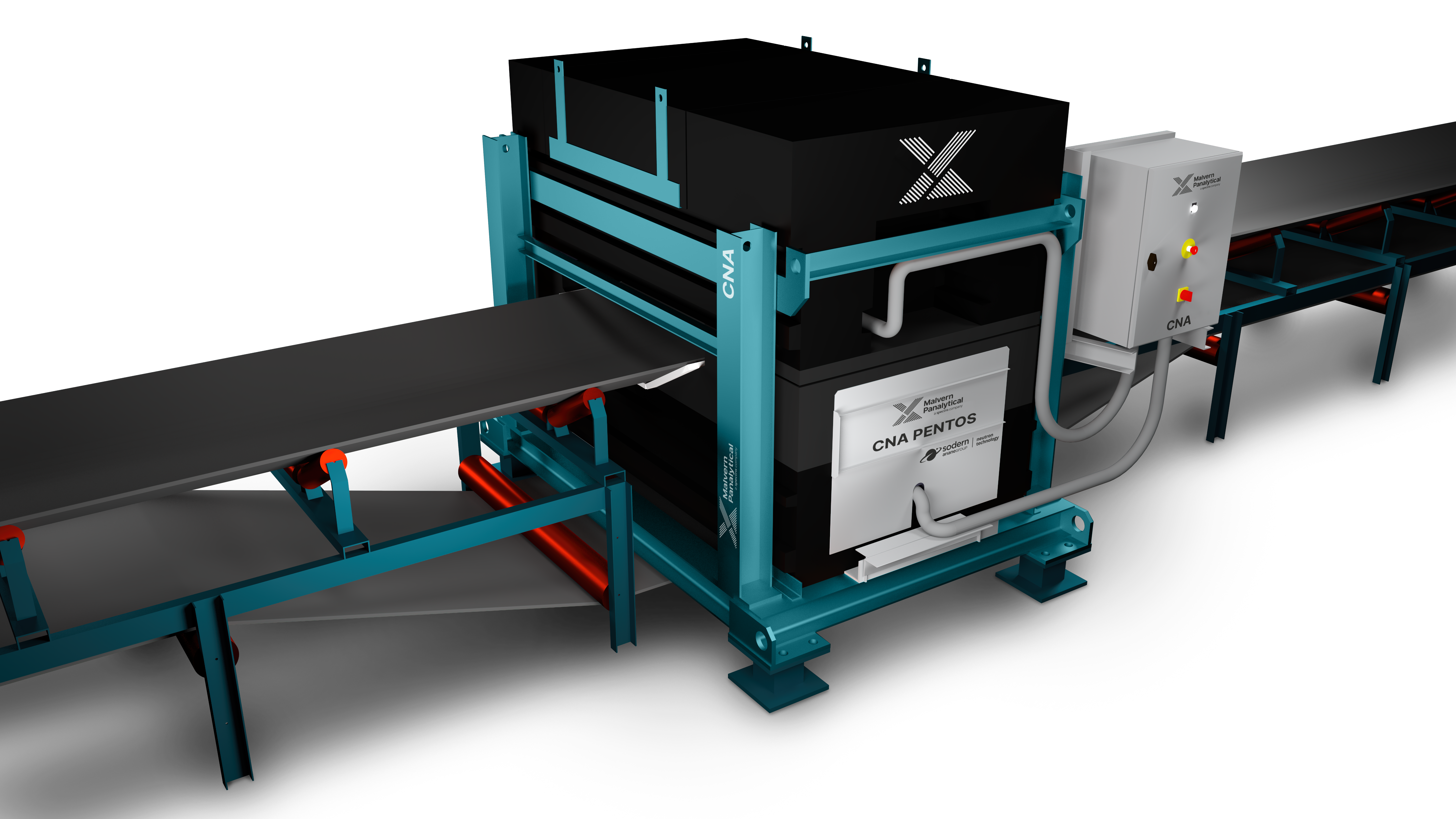

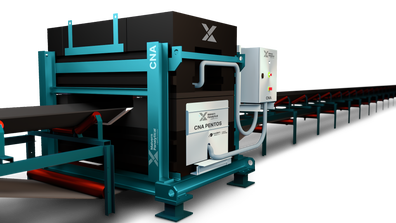

CNA Pentosは、世界で最も先進的なオンライン元素分析装置の第5世代の製品です。前の世代の製品と同様に、パルス高速熱中性子放射化(PFTNA)というSodern中性子技術をベースにしています。

PentosはCNAの最新リリースであり、SodernおよびMalvern Panalyticalのたゆみない製品改善の取り組みを反映しています。

- CNA Manager –新しいユーザーインターフェース

- ルト負荷の柔軟性

- キャリブレーションの柔軟性

- 信頼性の向上

- 検出器設計の改善

- 性子束調節の改善

- メンテナンスツールの強化

CNAを選ぶ理由

CNA Pentosは、大量の原料を高頻度で元素分析する機能を提供します。

最終結果は安定しており、ターゲットのキルン組成が得られ、残りのプロセス全体で効率と安定性が向上します。

費用のかかるサンプリング装置や検査室のスタッフを必要とすることなくリアルタイムでのプロセス制御を行うことができます。

機能

-

電気的オン/オフが可能な中性子源

-

自動放射線防護システム(ARPS)

-

モジュール式設計により、設置時のダウンタイムを最小限に抑制

-

直接リンク診断プログラムを内蔵し、最適な動作と稼働時間を実現

-

中性子出力が一定であるため、費用と手間のかかる定期的なオンサイトキャリブレーションが不要

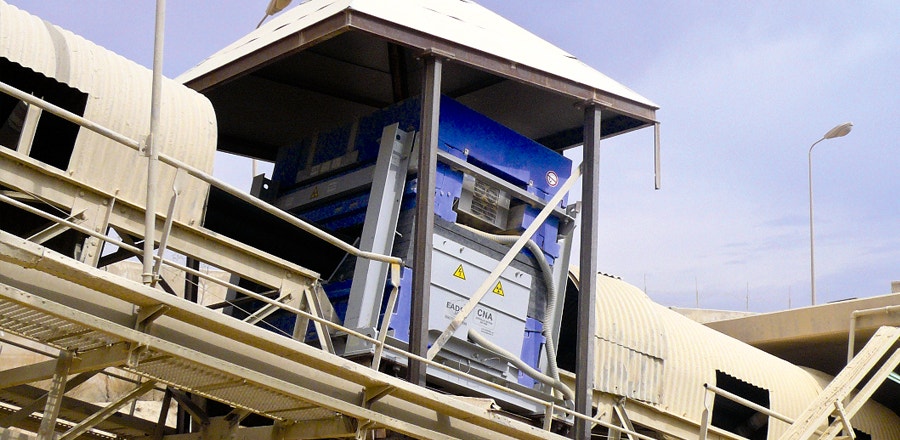

アプリケーション

-

- 採石場の管理

-

採石場にCNA Pentosを設置すると、備蓄に回される原料を迅速に分析することで、低グレードの原料を効果的に活用することができます。 これにより採石場の寿命が大幅に延びます。

- 備蓄の最適化

-

CNA Pentosを備蓄上前に設置すると、鉱石の品質目標が満たされ、元素組成のばらつきが低減され、回収時の補正が最小限ですみます。

- 原料混合物の制御

-

CNA Pentosを使用すると、原料混合物の元素組成を1分間隔で測定します。 これにより、ミル搬送の遅延なしで混合比を即座に補正できます。 最終的に、ターゲットを満たす安定した原料混合物を供給して、安定した炉運転が可能になり、燃費を低減し、耐火寿命が延びます。

- コスト削減の機会

-

- 炉運転の改善

- ラボのコストと準備作業を低減

- 研削効率を向上させながら、研削にかかるエネルギーコストを低減

- 炉の耐火寿命を延長

- 添加剤の使用を低減

- 採石場の寿命を延長

PFTNAの利点

CNA Pentosクロスベルト分析装置は、パルス高速熱中性子放射化(PFTNA)分析を使用して原材料の化学的性質を迅速に判定するため、リアルタイムプロセス制御が可能になります。

CNAは、中性子を使用して材料に「照射」することで、ベルト上原料の元素組成を分析し、きわめて代表的なデータを提供します。

パルス励起により、サンプルから高品質の時間分解されたガンマ線スペクトルを生成します。 これにより、S/N比が大幅に改善され、高い精度と確度が得られます。