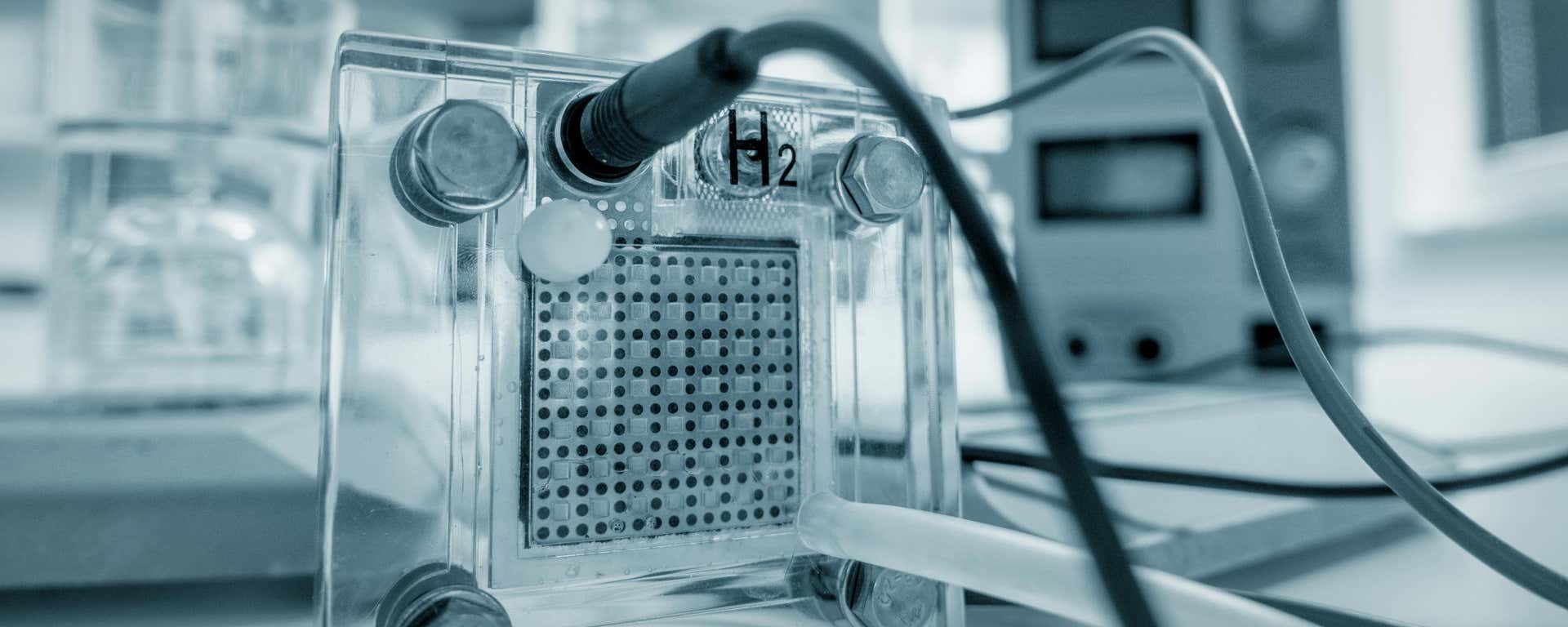

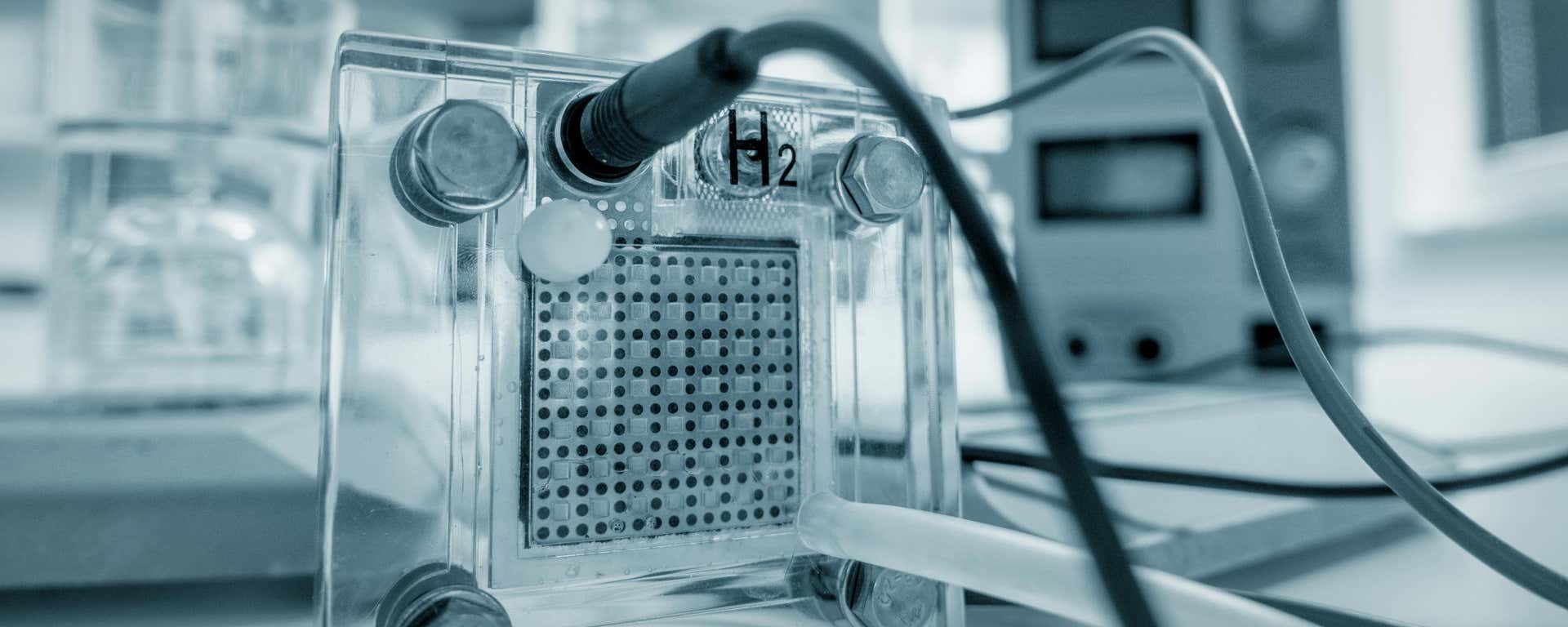

氫催化劑分析

氫可以成為潔淨能源載體,減少各類領域對化石燃料的依賴,並為脫碳提供強大助力:

氫氣支援超過 60% 的高 GHG 排放應用,且其全球碳減量占比預計將於 2050 年前達到 20%,對於淨零碳排放的未來至關重要。

氫催化劑對於提高氫氣生產、儲存與使用的效率方面至關重要。它們的功用遍及多項技術:

氫經濟的關鍵要素包括:

技術:

材料:吸附劑、薄膜、催化劑

測量目標:

技術

氫氣可用以下形式儲存:

材料:吸附劑、催化劑

測量目標:

技術

氫氣具有多種用途:

材料:薄膜、催化劑、吸附劑

測量目標:

體積小但功能強大的攜帶式 XRF 分析儀

高效能氣體吸附