Particle size and size distribution are often important parameters in defining product performance. Measuring these at an early stage in development is therefore of significant benefit to researchers who need to engineer specific product attributes. Here we describe how the Hydro SV can support this requirement.

Particle size and size distribution are often important parameters in defining product performance. Particle size measurement can be used as a tool to predict and control properties such as product stability, uniformity, flowability and appearance, and can also help with understanding the processability of a new material. Measuring particle size at an early stage in development is therefore of significant benefit to researchers who need to engineer specific product attributes.

One of the challenges associated with carrying out particle size distribution measurements during early development is that the amount of material available may be limited. The ability to measure small volume samples is therefore important. However, it is also important to consider how the selected measurement method can be scaled up to handle larger sample quantities during the later stages of development and production. This allows any specifications set at an early stage to be carried forward.

In this application note, we consider the use of the Mastersizer 3000 laser diffraction system as a particle characterisation tool which can be used throughout a product’s development lifecycle. The Mastersizer 3000’s Hydro SV small volume dispersion unit is designed to enable measurements during early stage development, while the larger volume Hydro MV, Hydro EV and Hydro LV dispersion units are designed to measure larger samples as part of product scale-up and manufacturing. Two different materials are considered – a product with a coarse particle size and one with a finer particle size – representing different measurement challenges in terms of sampling and dispersion. We aim to show that specifications developed based on Hydro SV measurements can be transferred to the larger volume dispersion units.

One of the challenges associated with transferring particle size specifications from small to large volume sample measurements relates to control of the process used to select a sample for analysis. This is often the biggest source of measurement variability when measuring coarse materials which contain particles larger than 70-100 µm in size [1]. Once a sampling procedure is selected, the material must then be presented to the laser diffraction measurement system in a way that ensures that the entire size distribution is measured in a representative way. The requires control of the suspension of the sample during measurements.

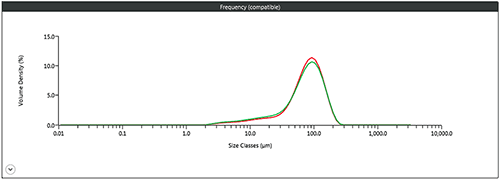

Figure 1 shows the particle size distributions obtained for a coarse material using the Hydro SV (6ml dispersant volume) and the Hydro MV (120ml dispersant volume). The particle size distribution of this material is broad (it extends over greater than one decade in size) and it contains large particles, so sampling must be controlled if similar results are to be obtained at small and large volumes.

|

As can be seen in figure 1, the results produced using each dispersion unit are similar and are consequently directly comparable. This is confirmed in table 1, which shows the median particle size (Dv50), 90th percentile (Dv90) and distribution width (Span) reported using each accessory. Close agreement is shown for these parameters, giving confidence in the accuracy of the results obtained at small volumes.

| Accessory | Mean Dv(50) / µm | Mean Dv(90) / µm | Mean Span |

|---|---|---|---|

| Hydro SV | 77.8 | 147 | 1.6 |

| Hydro MV | 79.8 | 146 | 1.5 |

The data signify that the specifications established at an early R&D stage for this product can be efficiently transferred across to later development or production. This will not only ensure consistent product quality but also aid any trouble shooting which may be required during the scale-up process.

Another challenge associated with particle size measurement is dispersion [2]. This is often the largest source of measurement variability when measuring fine materials which contain colloidal particles (particles less than 20 µm in size). For the Hydro SV, the state of dispersion of the sample must be controlled prior to adding the sample to the unit for measurement, as the unit does not include a sonication probe. In contrast, the Hydro MV provides the ability to sonicate the sample during an automated measurement sequence, providing a greater degree of dispersion control. Transferring specifications between the units during scale up therefore requires the dispersion process to be understood and controlled.

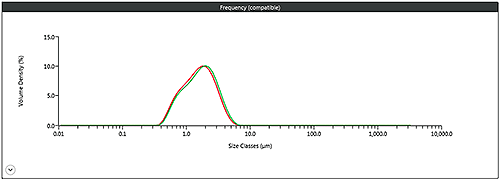

Figure 2 shows a the particle size distributions measured using the Hydro SV and Hydro MV for a typical micronized material. The entire size distribution for this sample is below 20 µm in size, so dispersion needs to be controlled if equivalent results are to be obtained. In the case of the Hydro SV, the sample was dispersed using an external sonication bath prior to the sample being added to the dispersion unit, whereas internal sonication was used with the Hydro MV.

|

As can be seen in figure 2, the results produced using each dispersion unit are similar. The Dv50, Dv90 and Span are also comparable (table 2), suggesting that the dispersion process is under control for both sets of measurements. As with the first case study, this gives confidence that the data obtained using the Hydro SV are representative, and that any specifications derived from this data can be used as the basis for controlling the scale-up process.

| (API) Accessory | Mean Dv (50) (µm) | Mean Dv (90) (µm) | Mean Span |

|---|---|---|---|

| Hydro SV | 1.68 | 3.33 | 1.5 |

| Hydro MV | 1.58 | 3.12 | 1.5 |

Particle size and size distribution are often critical parameters in defining the properties of materials. Measuring these early in the development of a new product is therefore advantageous. The data presented here confirm the ability of Mastersizer 3000 to generate comparable results for different sample sizes using the Hydro SV and Hydro MV dispersion units. The ability to consistently measure small and large volume samples enables laser diffraction to be used in support of the earliest stages of product development, as well as during product scale-up for manufacturing.

[1] WP051214 – Sampling For Particle Size Analysis. This is available from Malvern’s website.

[2] TN130222 - Wet or liquid dispersion method development for laser diffraction particle size distribution measurements. This is available from Malvern’s website.