For quality and process control many elemental analysis techniques are available. ICP, AAS, ICP-MS, ICP-OES and X-ray fluorescence spectroscopy (XRF) are traditional techniques used in many industries. Each of these techniques has a number of advantages and disadvantages giving the analyst the flexibility to choose which technology suits best. When the required limits of quantifications are above 1 ppm (µg/g), or when non-destructive analysis is required, XRF is a very attractive technique that should be considered, especially when analyzing solids, powders, slurries, filters and oils.

Opposed to ICP and AAS, XRF spectroscopy does not require sample dissolution or digestion, therefore allowing for essentially non-destructive analysis. By avoiding the potential for inaccuracies caused by incomplete dissolution and large dilutions, the complete analysis by XRF helps to ensure the accuracy and reliability of results.

Five of the many advantages of XRF are discussed:

1. Simple, fast and safe sample preparation without chemical waste

2. Non-destructive analytical technique

3. Low cost of ownership

4. Analysis at the production site (at-line)

5. No need for daily re-calibration

Measurements by XRF are carried out directly on the solid material (or liquid) with little to no sample preparation. XRF analyzers can work with any type of sample without the need for dilution or digestion and therefore no disposal of chemical waste is necessary. Transferring liquids in wet-chemical methods from one vessel to another can introduce contamination and/or loss of material.

Measuring relatively large sample volumes (100 mg up to 10 grams) results in a more representative characterization of the sample. Also, errors due to sample inhomogeneity are easily minimized by using larger sample volumes. XRF can measure gram quantities without any risk of cross contamination and therefore the error in an XRF result is much smaller.

In benchtop XRF spectrometers the sample is excited using an X-ray tube and the characteristic X-rays from the sample are detected and automatically processed by the software. These low-power X-ray tubes don’t produce an extensive amount of X-ray photons or heat and therefore don’t damage the sample or alter its crystal structure.Irregularly shaped samples that fit into the spectrometer can be analyzed without the need of destructive sample preparation, like crushing and grinding.

The same sample that was analyzed by XRF can later be analyzed using other techniques for further investigation, if necessary.

To continue reading, please login or register for a free account.

For quality and process control many elemental analysis techniques are available. ICP, AAS, ICP-MS, ICP-OES and X-ray fluorescence spectroscopy (XRF) are traditional techniques used in many industries. Each of these techniques has a number of advantages and disadvantages giving the analyst the flexibility to choose which technology suits best. When the required limits of quantifications are above 1 ppm (µg/g), or when non-destructive analysis is required, XRF is a very attractive technique that should be considered, especially when analyzing solids, powders, slurries, filters and oils.

Opposed to ICP and AAS, XRF spectroscopy does not require sample dissolution or digestion, therefore allowing for essentially non-destructive analysis. By avoiding the potential for inaccuracies caused by incomplete dissolution and large dilutions, the complete analysis by XRF helps to ensure the accuracy and reliability of results.

Five of the many advantages of XRF are discussed:

1. Simple, fast and safe sample preparation without chemical waste

2. Non-destructive analytical technique

3. Low cost of ownership

4. Analysis at the production site (at-line)

5. No need for daily re-calibration

Measurements by XRF are carried out directly on the solid material (or liquid) with little to no sample preparation. XRF analyzers can work with any type of sample without the need for dilution or digestion and therefore no disposal of chemical waste is necessary. Transferring liquids in wet-chemical methods from one vessel to another can introduce contamination and/or loss of material.

Measuring relatively large sample volumes (100 mg up to 10 grams) results in a more representative characterization of the sample. Also, errors due to sample inhomogeneity are easily minimized by using larger sample volumes. XRF can measure gram quantities without any risk of cross contamination and therefore the error in an XRF result is much smaller.

In benchtop XRF spectrometers the sample is excited using an X-ray tube and the characteristic X-rays from the sample are detected and automatically processed by the software. These low-power X-ray tubes don’t produce an extensive amount of X-ray photons or heat and therefore don’t damage the sample or alter its crystal structure.Irregularly shaped samples that fit into the spectrometer can be analyzed without the need of destructive sample preparation, like crushing and grinding.

The same sample that was analyzed by XRF can later be analyzed using other techniques for further investigation, if necessary.

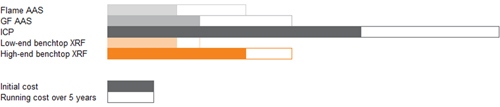

Taking into account the initial costs of instrument and infrastructure, and running costs of gasses, acids, electricity and waste disposal, XRF benchtop spectrometers are far more cost-effective than ICP and AAS. XRF does not require the use of expensive acids, gasses and fume hoods. The only requirement is mains electricity and in some cases the use of helium to boost the sensitivity for light elements in the sample. Also, the individual components in XRF spectrometers are not exposed to friction or heat and therefore last for many years.

For example, the analysis of oils only requires the use of inexpensive disposable liquid cups. Solid samples, like metals, can be measured ‘as is’ with no sample preparation. If that’s not cost-effective!

Since no gasses, liquids, acids and fume hoods are necessary to operate the XRF benchtop spectrometer, the instrument can be placed in the production facility, right next to the production line for at-line process control. The instrument is easy to install and with a short and basic training on the software, the user can operate the instrument with confidence.

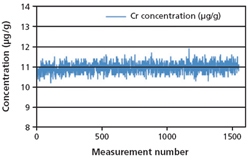

The latest advances in excitation and detection technology make the current generation of XRF benchtop spectrometers very stable. In comparison with ICP and AAS, XRF doesn’t need gasses or liquids to operate. Therefore, changes in the calibrations due to the purity and stability of gasses are not an issue for XRF, making daily re-calibration of the XRF instrument unnecessary.

For XRF spectrometers, gradual instrumental drift over years is easily corrected in the software and does not need a full re-calibration each time the spectrometer is in operation.