Malvern Instruments manufacture two variants of their Scirocco 2000 dry powder feeder; a standard unit which uses a stainless steel venturi and dispersion assembly and an abrasion-resistant unit where these parts are made of ceramic.

The stainless steel unit is built to handle most applications. It is conductive in nature and is therefore the unit of choice in applications where static charge build-up may be a problem (e.g. when measuring samples such as flour). However, it should not be used for abrasive materials, such as cement, as these may rapidly erode the stainless steel. The ceramic variant has been produced exclusively for these materials.

Ceramic as a material exhibits a high abrasion resistance because of its higher surface hardness compared to stainless steel. This difference in surface properties can change the degree of dispersion or particle break-up experienced at a given pressure using each venturi. The harder ceramic material tends to yield greater agglomerate break-up at a given pressure. Increased particle attrition would also be expected, especially when measuring friable materials such as some pharmaceutical excipients and actives. It is therefore important that the venturi type is chosen to suit the application i.e. ceramic should only be used where abrasive materials are to be measured. It is also important that, once the venturi type has been chosen for a given application, any additional dry powder feeders used to measure the same product should use the same venturi type. This will aid in obtaining good instrument-to-instrument comparability and the transfer of SOPs to other sites within the same company.

If, for any reason, a stainless steel variant is preferred for an application where ceramic has been used in the past, a pressure titration should be performed to establish the correct pressure which will efficiently disperse the sample without giving rise to attrition. Provided that the same procedure has already been conducted for the ceramic venturi version of the dry powder feeder, it will be found that good agreement will be obtained between units even though the pressure recommended for each of the two variants may be different.

Sample Name | Dv10 / mm | Dv50 / mm | Dv90 / mm |

|---|---|---|---|

Averaged ceramic (4 bar) | 2.32 +/-0.08 | 5.47+/- 0.02 | 11.68 +/- 0.03 |

Averaged stainless (4 bar) | 2.77+/-0.02 | 6.86 +/- 0.08 | 14.71 +/- 0.18 |

|

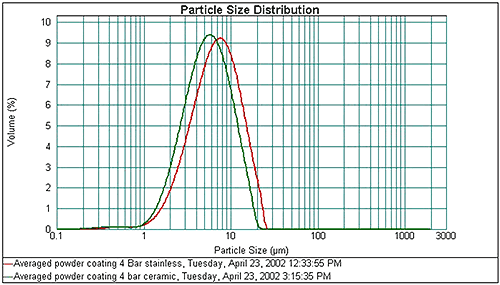

Table 1 provides the average particle size distribution statistics calculated over five repeat measurements for the dispersion of a powder coating sample at 4 bar using both the ceramic and stainless steel venturi. A comparison of the size distributions is given in figure 1. As can be seen, obvious differences exist between the results obtained on each unit. Typically, a measurement reproducibility of better than 2% is achievable using the Scirocco dry powder feeder. The differences observed are greater than this, suggesting that the venturi type is important. The results obtained on the ceramic venturi are shifted to smaller sizes compared to the stainless steel unit, demonstrating the attrition caused by the action of the harder ceramic surface on the sample.

Sample Name | Dv10 / mm | Dv50 / mm | Dv90 / mm |

|---|---|---|---|

Averaged ceramic (3bar) | 2.89 +/-0.02 | 6.82+/- 0.03 | 14.33 +/- 0.10 |

Averaged stainless (4 bar) | 2.77+/-0.02 | 6.86 +/- 0.08 | 14.71 +/- 0.18 |

|

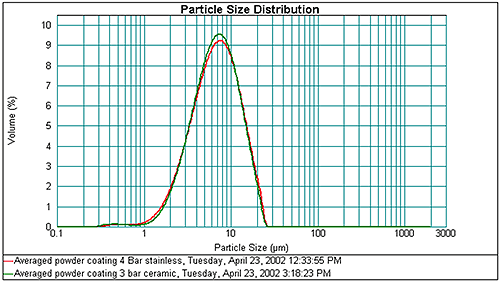

A comparable degree of dispersion can be achieved using each unit by reducing the pressure used for the ceramic venturi measurements to 3 bar. This is clearly shown in table 2. The corresponding size distribution over-plot is given in figure 2. As can be seen, the results obtained are now comparable.

The Scirocco dry powder feeder can be supplied in two different variants; one with a ceramic venturi and one with a stainless steel venturi. Each of these has been designed to meet specific application requirements. The different properties of ceramic and stainless steel do, however, cause each variant to yield slightly different results on the same sample measured at a fixed dispersion pressure. It is therefore important that, once the venturi type has been chosen for an application, any additional dry powder feeders used to measure the same product should use the same venturi type. A pressure titration should be carried out to determine the dispersion pressure required to obtain comparable results on each variant if this is not possible.