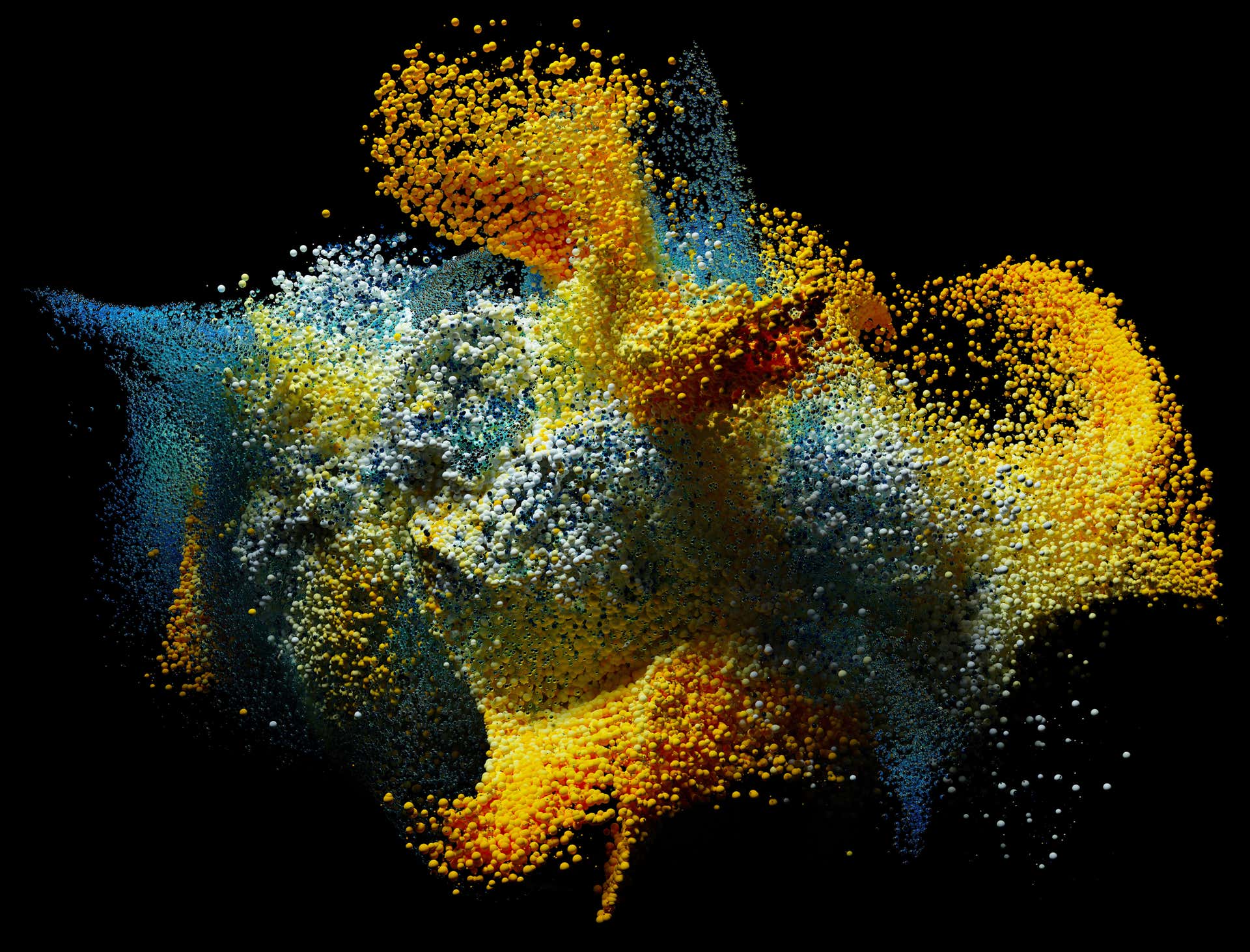

FT4 powder rheometer

Analyze powder flow properties and powder behaviour

Measuring the rheological properties of materials using a rheometer

Rheology is defined as the study of the flow and deformation of matter, which describes the interrelation between force, deformation and time.

A rheometer is a device used to measure the rheological properties of materials.

Unlike a viscometer, which can only measure the viscosity of a fluid under a limited range of conditions, a rheometer is capable of measuring the viscosity and elasticity of non-Newtonian materials under a wide range of conditions.

Some of the most important properties that can be measured using a rheometer include:

Rheometers can also process relevant parameters such as die swell and melt fracture.

How does it work?

A powder sample is subjected to controlled flow or consolidation within a test chamber to evaluate its dynamic, shear, and bulk properties. By measuring resistance to movement under varying conditions, data on flowability, cohesion, and compressibility are obtained. The applied stresses and resulting behaviors simulate real-world processing environments, helping to optimize handling, transport, and formulation performance.

The FT4 powder rheometer measures powder flow resistance uniquely, using a precision blade that rotates and moves downward, creating a controlled flow pattern. The resistance experienced by the blade reflects how easily the particles move relative to one another, indicating bulk flow properties.

What is it useful for?

How does it work?

A sample is forced to extrude through a barrel or die of well-defined dimensions under high pressure. The pressure drop across the barrel or die is measured to give pressure-flow rate data for the fluid, from which viscosity is calculated. Temperature and shear rate can be closely controlled to simulate the processing environment of interest

What is it useful for?

Analyze powder flow properties and powder behaviour

The FT4 measures powder flow resistance using a precision blade that rotates and moves downward, creating a controlled flow pattern. The resistance experienced by the blade reflects how easily the particles move relative to one another, indicating bulk flow properties.

Key features: