Fast & reliable through-pore size distribution analysis

Capillary flow porometry, also referred to as gas liquid porometry (GLP), is a technique employed to accurately measure the size and distribution of throughpores within membranes and sheet materials.

This pressure-based method determines the largest throughpore diameter by analyzing gas flow through a liquid-saturated sample, covering a large test area without requiring complex model-fitting or image processing.

Understanding the fundamentals of capillary flow porometry begins with recognizing its basic mechanism. Capillary flow is concerned with the movement of liquid through a porous medium under the influence of capillary forces. These forces are essential to calculating the size of the minimum pore constriction. Unlike methods that rely on indirect estimations or image-based computations, capillary flow porometry directly measures the liquid flow through pores, ensuring straightforward and reliable results.

The analysis begins by completely saturating the sample with a wetting liquid, at which point it’s exposed to a gradually increasing flow of gas. This gradual increase in gas pressure forces the liquid out of the pores. The pressure at which the liquid displacement occurs helps to characterize the pore size; larger pores are emptied at lower pressure, while smaller pores require higher pressure. After all pores are opened and all wetting liquid has been expelled, flow across the un-wetted dry sample is measured.

Optimize the number and size of throughpores in order to better predict and ensure size-based selectivity and mass-transfer rate.

These common choices for filtration media are often characterized by a broad distribution of pore sizes due to their production methods. Steady flow determination of bubble point is especially important due to In-plane porosity and irregular pore shapes.

These materials, often with highly porous structures, are preferred for their thermal, physical, and chemical resistance. It is especially important to measure the three-dimensional porosity in the direction of the intended flow of these materials.

Device safety is enhanced through optimization of the rate of ion transport and physical separation.

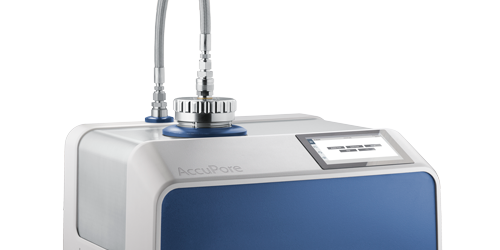

The Micromeritics AccuPore capillary flow porometer includes: