Viscosity measurement and applications

Viscosity is an important property of fluids that describes a liquid's resistance to flow and is related to the internal friction within the fluid.

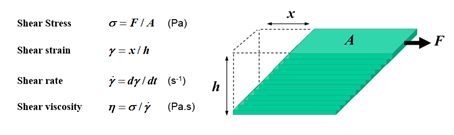

The most common type of flow behavior is shear flow where layers of fluid move relative to each other in response to a shearing force. This external force takes the form of a shear stress which is defined as the force acting over a unit area of fluid and results in a velocity gradient across the thickness of the sample termed the shear rate.

The shear viscosity or dynamic viscosity related to this process is given by the ratio of the shear stress to the shear rate as illustrated below:

Many simple fluids are classed as Newtonian meaning their viscosity is independent of the amount of shear applied. Examples would be water and simple hydrocarbons.

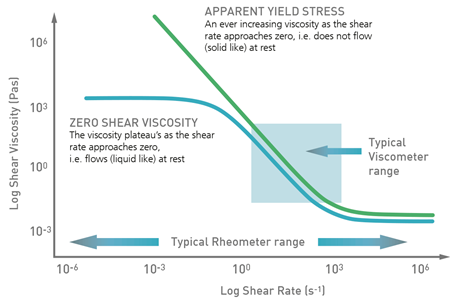

As fluid complexity increases, for example by the inclusion of bubbles, droplets, particles or polymers, fluids may take on more complex behavior and show a non-Newtonian response, where viscosity depends on the amount of applied shear. These types of fluids are generally called structured fluids or complex fluids.

Such non-Newtonian behavior is common for many industrial and commercial products including toothpaste, mayonnaise, paints, cosmetics and cements, which are generally shear thinning fluids, where viscosity decreases with increasing shear rate, although shear thickening can occur in some very structured fluids.

For most products, the viscosity is required to be high at low shear rates to prevent sedimentation or slumping, but to thin down at higher shear rates to facilitate application or processing. Hence a single viscosity measurement is not sufficient to describe the viscosity of such materials and the viscosity should be measured over a range of shear rates or stresses, or at least at a shear rate relevant for the process or application of interest.

Non-Newtonian fluids may also show other phenomena such as yield stress, thixotropy and viscoelasticity that can have a major impact on material behavior and product performance.

Other viscosity parameters which are related to dispersions are the relative viscosity, specific viscosity and intrinsic viscosity, which can give a measure of the solute or dispersed phase contribution to the viscosity of a solution or dispersion.

These parameters are most easily determined using a differential viscometer.