Overview

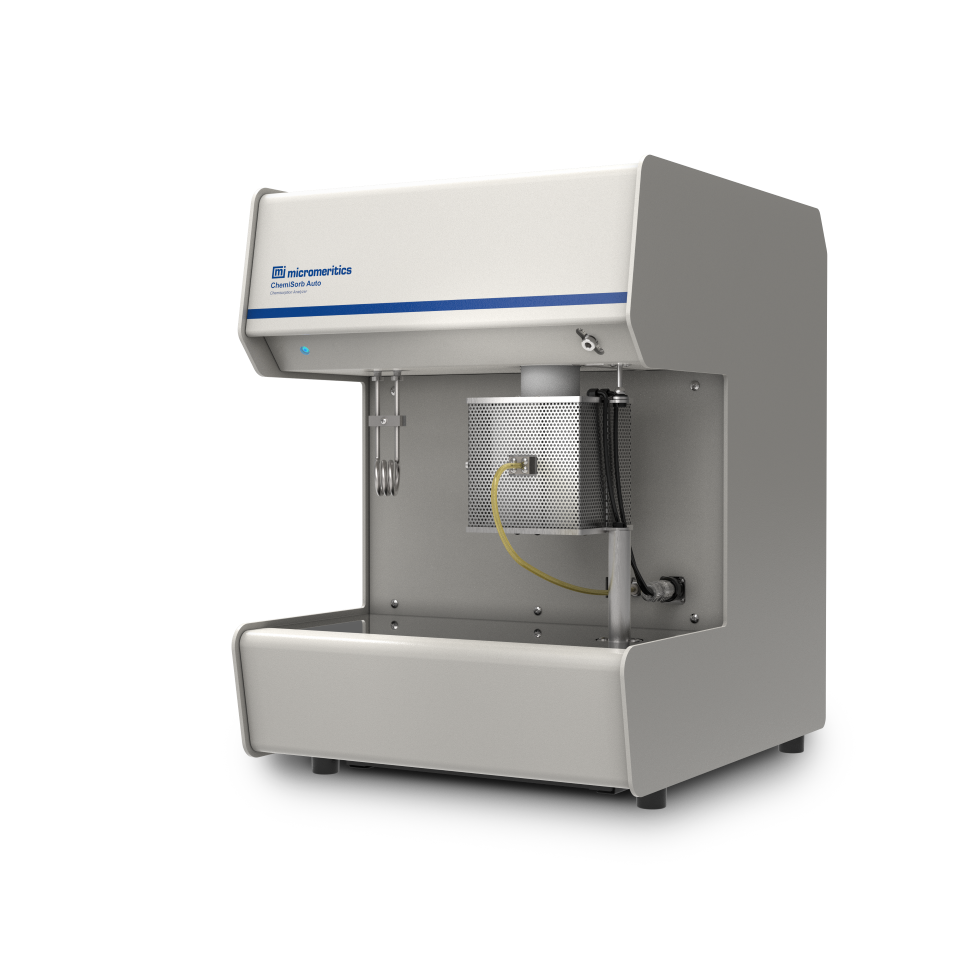

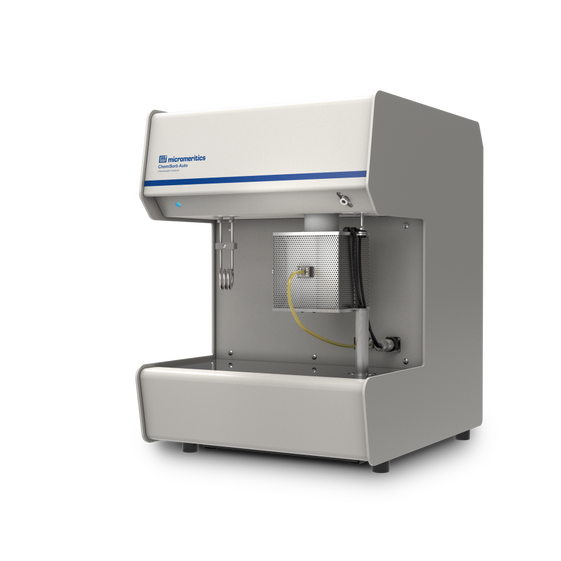

The Micromeritics ChemiSorb Auto is a compact, fully automated chemisorption analyzer designed to deliver high-precision, repeatable results for heterogeneous catalysts.

Whether you're conducting temperature-programmed experiments or pulse chemisorption analyses, the ChemiSorb Auto offers reliable performance, affordable access, and unmatched ease of use – all in a benchtop footprint.

Features

-

Patented blending valve: allows precise gas blending and multi-point automatic gas calibrations

-

Loop pressure measurement: exact quantities of gas dosed to the sample are known, ensuring repeatability within +/- 1%

-

8 total gas inlets: four each for carrier and loop gases fed to the system with two high-precision mass flow controllers

-

Optional cryocooler: enables the start of an analysis at sub-ambient temperature, down to -100°C

-

Minimal internal gas volume: assures high resolution, fast detector response, and reduces error when calculating gas volumes

-

Highly sensitive linear thermal conductivity detector (TCD): assures the calibration volume remains constant over the full range of peak amplitudes so the area under the peak is directly proportional to the volume of gas reacted

-

Forced air cooling: cools the furnace temperature rapidly down to near ambient (500°C to 50°C in 30 minutes), reducing analysis time and increasing throughput

-

Dynamic clamshell furnace: provides temperature control up to 1000°C and controlled heating rates from 1-50°C at a linear rate with minimal temperature overshoot

Key applications

Hydrocracking catalysts typically composed of metal sulfides (nickel, tungsten, cobalt, and molybdenum) are used for processing feeds containing polycyclic aromatics that are not suitable for typical catalytic cracking processes.

The water gas shift reaction is an important element in the hydrogen lifecycle and the push toward net zero technologies. The combination of catalysts, often copper-zinc-alumina and iron-chromium, are characterized by TPR and pulse chemisorption maximize activity.

Fischer–Tropsch synthesis converts syngas into sustainable fuels, with cobalt and iron catalysts playing a key role. Chemisorption and TPR techniques help optimize metal dispersion and reducibility, directly enhancing catalytic performance.

Catalysts containing platinum, rhenium, tin, etc. on silica, alumina, or silica alumina are used for the production of hydrogen, aromatics, and olefins.

Catalysts such as small-pore zeolites (mordenite and ZSM-5) containing noble metals (typically platinum) are used to convert linear paraffins to branched paraffins.

Manganese, cobalt, bismuth, iron, copper, and silver catalysts used for the gas-phase oxidation of ammonia, methane, ethylene, and propylene are characterized using: Temperature-programmed oxidation and desorption, heat of desorption & dissociation of oxygen.

Catalysts like palladium, nickel, and platinum rely on chemisorption to activate hydrogen and substrate molecules, with techniques like pulse chemisorption and TPR used to fine-tune activity and selectivity.

Acid catalysts such as zeolites are used to convert large hydrocarbons to gasoline and diesel fuel. The characterization of these materials includes: Ammonia chemisorption and temperature-programmed desorption.