Overview

The Micromeritics HPVA II (High-Pressure Volumetric Analyzer) uses the static volumetric method to obtain high-pressure adsorption and desorption isotherms utilizing gases such as hydrogen, methane, and carbon dioxide.

Analyze a variety of materials, including MOFs, zeolites and microporous carbons using just a few milligrams of sample.

Obtain a better understanding of applications such as hydrogen storage, carbon dioxide sequestration, fuel cells and batteries, and hydrocarbon traps.

Features

The Micromeritics HPVA II offers four methods of sample temperature control:

- Refrigerated/heated recirculation vessel (customer provides temperature control bath)

- Four-liter, stainless-steel dewar for liquid cryogen

- Furnace allows for experiments ranging up to 500 °C

- Cryostat can precisely control sample temperatures from ambient conditions to 30 K

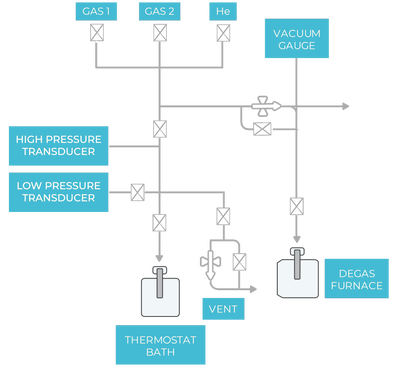

System schematic

-

Manifold: all the valves in the manifold are pneumatically operated, high-pressure valves with Kel-F® seats. Valve tubing is constructed with heavy wall, 316L stainless steel and is attached via a VCR connection or welded. The temperature of the insulated manifold region is stabilized using a heater controlled by an adjustable PID controller.

-

Pressure transducers: two transducers are used to precisely measure the system pressure. A 1000-torr transducer is used to accurately monitor pressures below 1 atmosphere and is protected from high pressure with an isolation valve and a cracking valve that relieves to the vent.

-

Servo valves: the servo valves are used to automatically regulate the flow of gas in the manifold to the vent and vacuum.

-

Vacuum system: consists of a mechanical pump and internal Pirani vacuum gauge. User can provide their own pump or purchase the high-vacuum turbo pump package.

Why HPVA II?

- Dual free-space measurement for accurate isotherm data

- Free space can be measured or entered

- Correction for non-ideality of analysis gas using NIST REFPROP compressibility factors calculated from multiple equations of state

- Reports provided as interactive spreadsheets

- Isotherm and weight percentage plots created automatically

- Tables of raw data used for report calculations

- Real-time charts for Pressure vs. Time and Temperature vs. Time

- Gas mixtures with up to three components can be used

- Kinetic data provided for rate of adsorpotion calculations

- Langmuir equation used to model Type I isotherms

- High-precision, solid-state design high-pressure transducer provides a reading accuracy of ±0.04% full scale with a stablility of ±0.1%

- Low-pressure pressure transducer provides a reading accuracy of ±0.15% of value

- System can attain a maximum pressure of 200 bar

- Hydrogen gas sensor automatically shuts down the system should a hydrogen leak occur

- BET surface area, Langmuir surface area, and total pore volume calculations included

Applications

Evaluating the quantity of carbon dioxide that can be adsorbed by carbons and other materials is important in the ongoing study of carbon dioxide sequestration. High pressures obtained with the HPVA II can simulate the underground conditions of sites where CO2 is to be injected.

Configuring the HPVA II with a chiller/heater bath allows the user to evaluate the CO2 uptake at a range of stable temperatures, providing data that can be used to calculate heats of adsorption.

These isotherms are typically analyzed up to approximately 50 bar at near ambient temperatures due to CO2 condensation at higher pressures.

Determining the hydrogen storage capacity of materials such as porous carbons and metal-organic frameworks (MOFs) is pivotal in the modern demand for clean energy sources.

These materials are ideally suited for storage because they allow you to safely adsorb and desorb the hydrogen. Stored adsorbed hydrogen in MOFs has a higher energy density by volume than gaseous hydrogen and does not require the cryogenic temperatures needed to maintain hydrogen in a liquid state.

The HPVA II software provides a weight percentage plot that illustrates the amount of gas adsorbed at a given pressure as a function of the sample mass − the standard method for reviewing a sample’s hydrogen storage capacity.

Porous coal samples from underground beds can be analyzed with the HPVA II to determine their methane capacity at high pressures. This allows the user to find the methane adsorption and desorption properties of the underground coal beds, which is useful in determining approximate amounts of hydrocarbons available in coal-bed reserves.

Kinetic data from the experiments can also show the rate of metane adsorption and desorption on these porous carbon samples at specific pressures and temperatures.

High-pressure methane can be dosed onto shale samples to generate adsorption and desorption isotherms. This provides the methane capacity of the shale at specific pressures and temperatures.

The adsorption isotherm can be used to calculate the Langmuir surface area and volume of the shale. The Langmuir surface area is the surface area of the shale, assuming that the adsorbate gas forms a single layer of molecules. The Langmuir volume is the uptake of methane at infinite pressure − the maximum possible volume of methane that can be adsorbed to the surface of the sample.