Hot news in research

New analytical methods for new research applications

New analytical methods for new research applications

Every day, researchers take steps into the unknown to discover more about the physical and natural world. Universities and research institutes, in particular, continually research to gain new knowledge.

At Malvern Panalytical, we love research just as much! Our scientists come here to help advance instruments and methods that turn research into knowledge and beyond. Sometimes, these instruments play a role in your lab – so we aim to make them user-friendly and even automated. Sometimes, measurements made with our instruments provide unique insight into established or emerging research fields. And sometimes, we develop techniques or equipment beyond established analytical methods. Over 150 of our full-time scientists across the world teach, study, and share how our analytical research solutions can be applied to established and newly emerging fields. From time to time, they also engage in joint publications with researchers.

Here, you’ll find some of these newest joint publications, as well as updates on our solutions in a research context. In the research theme pages, you’ll also find application notes providing an entry-level report on how our analytical solutions are used to gain knowledge in each research field. These application notes are the summaries of large bodies of work that often have a full publication behind them. Enjoy exploring!

Looking for support in an area that we haven’t covered? Don’t hesitate to reach out to us!

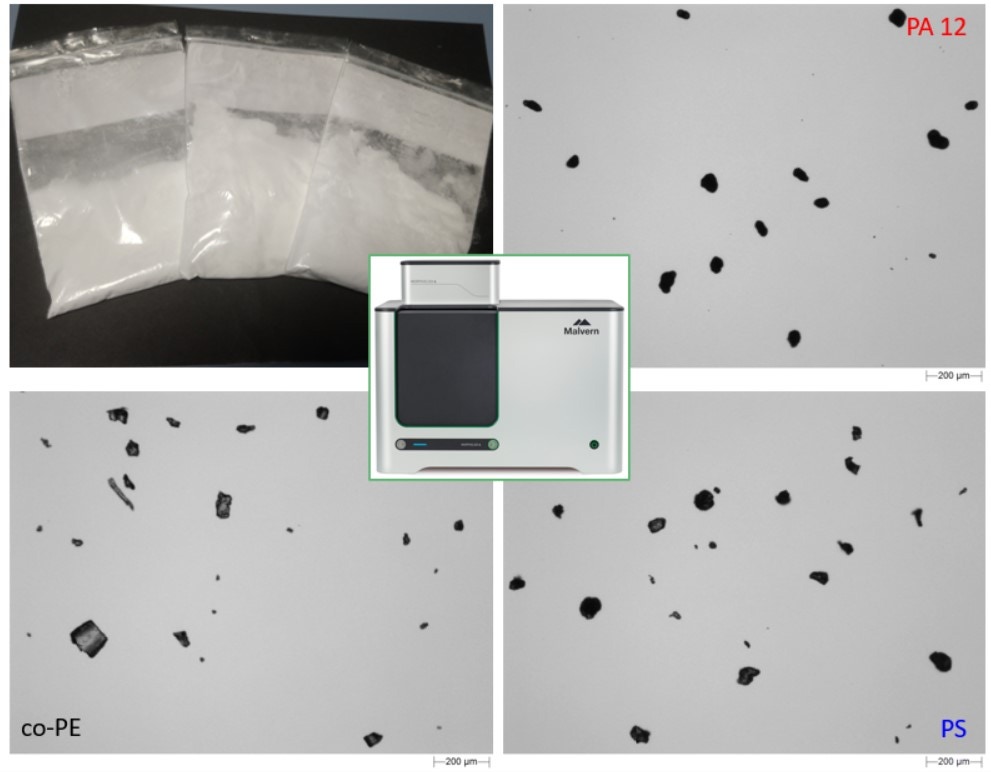

This work has been published in Additive Manufacturing Volume 47, November 2021, 102361, and was a result of our collaboration with Dr. Candice Majewski at the University of Sheffield in the UK. The Morphologi 4 was used to investigate the morphology of different polymers used in High Speed Sintering (HSS), a powder bed fusion Additive Manufacturing (AM) technology. The particle size and shape information obtained using automated image analysis can help to explain behaviors such as powder flow and packing. This analysis formed part of a larger study looking into what properties affect powder wettability/part color in the HSS process, as this can be linked to the mechanical properties of the final part. Through comprehensive characterization, more can be learned about how to optimize powders for these processes.

Interested in this application? You can find out more here:

Read the application note here.

Catalytic inks are the key component when balancing cost, performance, and durability of proton exchange membrane fuel cells (PEMFC’s). Particle size and dispersion critically impact the behavior of the ink and resulting performance of the electrode layers, affecting important parameters such as ink viscosity, ionomer distribution and morphology, catalyst utilization, interaction between the catalyst and ionomer, and the homogeneity and continuity of the electrode layer.

X-ray diffraction (XRD), laser diffraction (LD), and dynamic light scattering (DLS) are three characterization techniques each probing a different size regime and, when combined, can provide a comprehensive overview of the particles in the catalytic ink mixture.

Look out for our blog on Fuel cell on our Materials Talks portal on 25th March and our Webinar coming in April.

Want more information on this application, or to share your publication in this field? Contact us today!

Metal Organic Frameworks (MOFs) are a huge research area, so we’re excited that our research techniques can play a part. Our instruments can be used for detailed crystallographic analysis using X-ray diffraction to track changes under different operating conditions in real time. Or they can be used for physical characterization of manufactured MOF materials, in applications including:

At Malvern Panalytical, a dedicated focus group researches and compiles information on solutions for Metal Organic Frameworks (MOF). For instance, you may have seen our recent webinar: Characterization of Metal Organic Frameworks: The building of robust structures. If you missed it, you can watch it on-demand via this link.

A new webinar called "Advanced in-situ experiments on Metal Organic Frameworks" is coming soon - click here to register!

You can also download our MOF brochure here.

![[PN13596_DSC_2023_02_14_15_18_24-1_new_badge.jpg] PN13596_DSC_2023_02_14_15_18_24-1_new_badge.jpg](https://dam.malvernpanalytical.com/1dbe98eb-2ec1-49a3-bbf4-b07c00f31e94/PN13596_DSC_2023_02_14_15_18_24-1_new_badge_Original%20file.jpg)

We are very excited about this next stage in the Aeris evolution. Aeris was always designed to be a product that could evolve, and it is evolving into its own class of system. It is compact yet performs like a traditional floor standing system. Aeris occupies a unique position in the XRD market it is future proof and a good investment for any X-ray lab. On 23rd February we launched the Aeris XRD with its new features. If you missed the live launch, you can see a recording here. The launch was to introduce two new Aeris functionalities: X-ray diffraction in transmission and grazing incidence X-ray diffraction. If you want to know more, look at the new brochure and application notes.

Download the new Aeris brochure: Download brochure

That’s all for this news bulletin.

Got something you’d like us to share on this page? Contact our web team today!