Overview

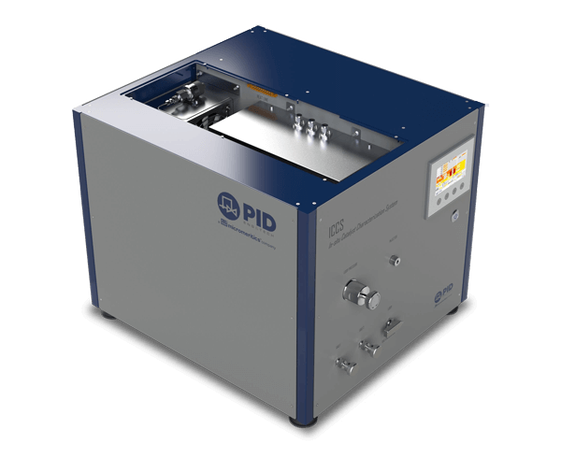

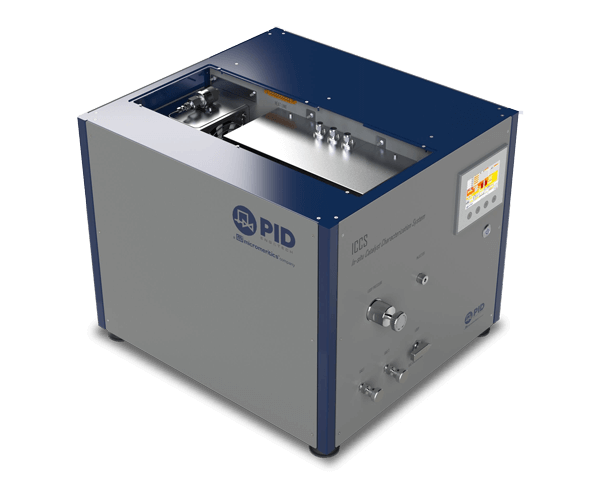

The Micromeritics ICCS in-situ Catalyst Characterization System is an advanced catalyst characterization tool that allows the user to study the impact of a reaction on critical parameters such as number of active sites, under precisely controlled, process-representative conditions.

A standalone accessory designed to complement any dynamic laboratory reactor system, such as the Micromeritics Flow Reactor, the ICCS adds two new capabilities: Temperature Programmed Analyses (TPx) and Pulse Chemisorption.

These well-known and time-tested techniques may now be performed on a fresh catalyst and then repeated on a used catalyst without removing the material from the reactor. This enables a detailed comparison of the catalyst, notably the number of active sites, before and after use. Users benefit from obtaining both temperature-programmed analyses and pulse chemisorption data for the same aliquot of sample used for reaction studies.

Performing these analyses in-situ virtually eliminates the possibility of contamination from atmospheric gases and moisture which may damage the active catalyst and compromise data integrity.

PID became part of Micromeritics in 2018, integrating its patented technologies, including ICCS, into the portfolio. In 2025, Micromeritics and PID joined Malvern Panalytical, bringing these exceptional instruments into the groups' materials characterization solutions.

Features and benefits

-

Two high-performance mass flow controllers for precise, fully automated gas flow control to enable TPx and pulse chemisorption analyses

-

Fully contained in-situ testing to allow multiple characterizations of the same catalyst using the same sample

-

A high precision Thermal Conductivity Detector (TCD) to monitor changes in the concentration of gases flowing into and out of the sample reactor in real-time

-

Touch screen, intuitive software and graphical interface for straightforward, streamlined operation and easy visualization and manipulation of alarms, commands and control parameters

-

Temperature-controlled stainless steel flow path for inert and stable operating environment and reduced potential for condensation; two internal temperature control zones may be operated independently

-

Internal cold trap with additional temperature control zone for removal of condensable fluids (e.g., water produced during reduction of oxides)

-

An ultra low volume flow path to minimize peak broadening and significantly enhance peak resolution

-

Corrosion-resistant detector filaments for durable compatibility with most commonly utilized TPx and pulse chemisorption gases

-

Interactive peak editor package to enable researchers to conveniently convert data to information; adjusting peak boundaries is just point and click

Operating principle

The typical operation of the ICCS begins with the loading of the catalyst into the reactor system. The catalyst may then be characterized by the temperature programmed methods:

- Temperature programmed reduction (TPR) is commonly used for supported metal catalysts

- Temperature programmed desorption (TPD) may be the best choice for acidic or basic catalysts

The TPx is often followed by pulse chemisorption to determine the number of active sites. This use of TPx and pulse titration provides a description of the fresh (unused) catalyst under representative conditions (notably at elevated pressure).

After performing this initial characterization, a user may then proceed with reaction studies on the exact same sample without adding any additional catalyst or transporting the catalyst to a different device.

Upon deactivation or simply after a prolonged period of testing, the used catalyst may then be analyzed in the same way as the fresh material employing TPx and pulse chemisorption under identical conditions. This strategy provides a method for comparing the key characteristics of the catalyst such as number of active sites, before and after use, without removing the catalyst from the reactor.