Overview

The Micromeritics Flow Reactor system is a benchtop turn-key flow reactor that provides:

A full range of process conditions

- Reaction conditions up to 1000 °C and 200 bar including patented wide-range control valves with stable control resolution to 0.1 bar

- Up to 6 gas and 2 liquid feed streams

- Continuously measured gas or liquid output streams with ultra-low dead volume including patented liquid/gas or liquid/liquid gas separators

A system that is quick to deploy and simple to use

- Automated software for completely unattended operation

- Integrated safety systems featuring alarms, fail-safes, and automated response to undesired conditions

- Benchtop system that allows testing catalyst samples from a few milligrams to several grams

De-risk your scale-up and shorten your development schedule with the Flow Reactor system that matches your process.

Features

-

Thermostated environmental chamber provides a stable isothermal process zone to eliminate condensation of vapors and provide long-term process stability.

-

Interchangeable reactors enable processes up to 1000 °C and 200 bar in materials that are suitable for a wide variety of reaction chemistries and low bed volume, simplifying the transition from bench- to flow reactor.

-

Independently-controlled reactor furnaces (FR-100: single, FR-200: dual) provide stable, uniform temperature control up to 1000 °C.

-

Liquid feed can be controlled through HPLC or syringe pumps for precise input flow control.

-

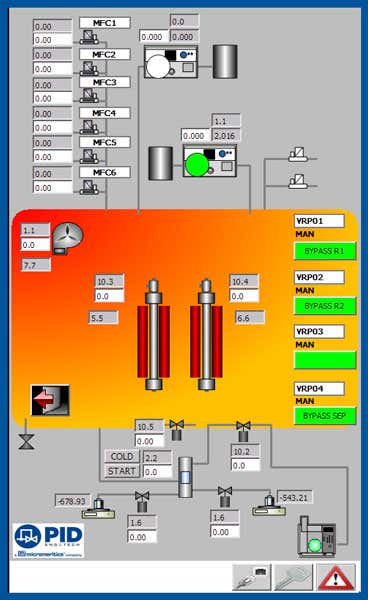

Touchscreen: the large full-color touchscreen provides a simple, real-time status display and modification of system settings.

-

Six gas inlets: Up to six gas inlets with precision mass flow controllers provide complete flexibility and control of process inputs.

-

Patented liquid-gas and liquid-gas separators provide effective product separation, less than 1 cc dead volume, and continuous output flow without accumulation (US Pat 7,895,891 B2).

-

Automatic six port valves for different flow paths such as reactor bypass or upflow/downflow operation.

-

Patented pressure-control valve provides stable control with a unique combination of wide dynamic range, high resolution, and ultra-low dead volume for any stream type. Features include ambient to 200 bar, 0.1 bar control resolution, and gas, liquid, or multiphase streams.

System configurations

The FR-200 includes all the capabilities of the FR-100 with two independently-controlled reactors. Three available configurations of the FR-200 enable reactor flows of increasing complexity to mimic even the most intricate reactor process flows.

-

- FR-200 Duo

-

- Both reactors in series with final liquid/gas separation

- Both reactors in series with intermediate liquid/gas separation

- Single reactor in flow (1 or 2)

- Both reactors bypass

- FR-200 Twin

-

- Both reactors in series (R1 and R2)

- One reactor in flow (R1 or R2) while the other regenerates

- One reactor in flow (regeneration) while the other is bypassed

- One reactor in flow while the other is bypassed

- Both reactors bypassed

- FR-200 Parallel

-

- Both reactors in parallel

- Both reactors in parallel and L/G Sep 1 in bypass

- Both reactors in series

- Both reactors in series and L/G Sep bypassed

- One reactor in bypass while other is in flow

- Analysis of the raw material 1 or 2

- Both reactors bypassed

- Multi-catalyst reactors (MR)

-

Automated 4 or 8 independent, parallel lab reactors in one unit

Due to its high throughput testing capabilities, the versatile computer-controlled Micromeritics Multi Catalyst Reactor (MR) series enables scientists to accelerate catalyst research: The Micromeritics MR 4 or MR 8 evaluation units provide capabilities to investigate 120 kinetic data points per week. Researchers can comprehensively measure the activity and selectivity of heterogeneous catalysts for screening and kinetic studies.

The automated MR 4 and MR 8 provide operational flexibility for determining optimal reaction conditions and understanding operational challenges for a wide range of applications. Due to the units’ high level of flexibility and gas or optional liquids feeding systems, the MR 4 or MR 8 can be configured to individual application needs: reaction and regeneration, for example, can be carried in-situ and at consecutive stages thanks to the precise temperature-control and feeding system.

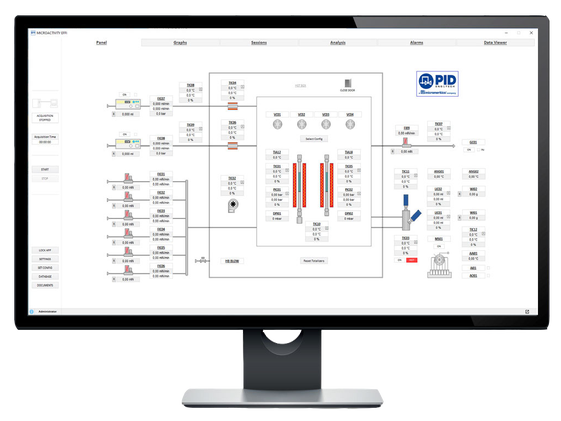

The Micromeritics MR 4 or MR 8 are easily integrated with a range of analytics including chromatography and spectroscopy and are operated or monitored via a user-friendly software that makes experimental study definitions easy.

Catalyst testing rates of 120 kinetic data points a week

Save time and resources during screening. Key Features:

- Fully automated modular system optimized for catalyst screening and providing reliable test studies

- Configurable to individual application needs ensures a high level of flexibility

- Flow reactor design accommodates both, extrudates and powders

- Inert reactor chamber made of quartz to avoid undesirable side reactions

- Gas and optional liquids feeding systems allow the MR-4 and MR-8 to be used for a wide range of applications

- Easily integrated with a range of analytics including chromatography and spectroscopy

- User-friendly software for defining experimental studies and continuous monitoring of the system

The high-productivity catalyst evaluation units are available in multiple configurations:

- Micromeritics Multi Catalyst Reactor MR 4 and MR 8: Fully automated, computer-controlled catalyst evaluation unit with 4 or 8 micro reactors for highly flexible screening studies

- Additional configurations are available on request: The number of reactors can be customized to your catalyst screening studies along with independent individual reactor control for kinetic studies and process design

MR 4 and MR 8 multi-catalyst reactors support the following studies

- Automated catalyst evaluation

- Parallel reaction screening

- Reaction kinetics

- Hydrogenation

- Reforming

- Hydrocarbon upgrading

- Catalytic conversion

- Methane activation

- Liquids derived from biomass, plastic, or tire valorization

- Selective oxidation and partial oxidation

- Custom reactor engineering

-

Want to move beyond the capabilities of the Flow Reactor series? The Micromeritics custom reactor engineering team has more than 25 years of experience developing high-performance custom reactors and small-scale pilot plots.

- Custom mini pilot plants

- Up to 50 g typical catalyst capacity

- Automated 24/7 operation

- Pre-designed modular components reduce construction time and cost

Example Processes

- Hydrotreating/reforming/cracking

- Biofuel production

- Exhaust/emission studies

- Gasification and pyrolysis

- Super-critical extraction

Flow reactor designs

Want to learn more about our solutions for major industrial processes?

Download our Flow Reactor Designs brochure to find out more about utilizing the Micromeritics Flow Reactor for a range of applications.

Applications

Liquid hydrocarbons & wax: liquid fuels and other chemical products can be produced from syngas via the well-known and catalytic chemical process called Fischer Tropsch (FT) synthesis.

Synthesis / decomposition: the Haber-Bosch process is an artificial nitrogen fixation process and is the main industrial procedure for the production of ammonia today.

One route to produce methanol is characterized by the addition of carbon dioxide to hydrogen.

Steam and dry: Steam methane reforming (SMR) is a process in which natural gas is heated with steam to produce a mixture of carbon monoxide and hydrogen used in organic synthesis.

Methane production: the Sabatier Process produces methane and water from a reaction of hydrogen with carbon dioxide at elevated temperatures.

Hydrogenation is a chemical reaction between hydrogen and another compound, usually in the presence of a catalyst.