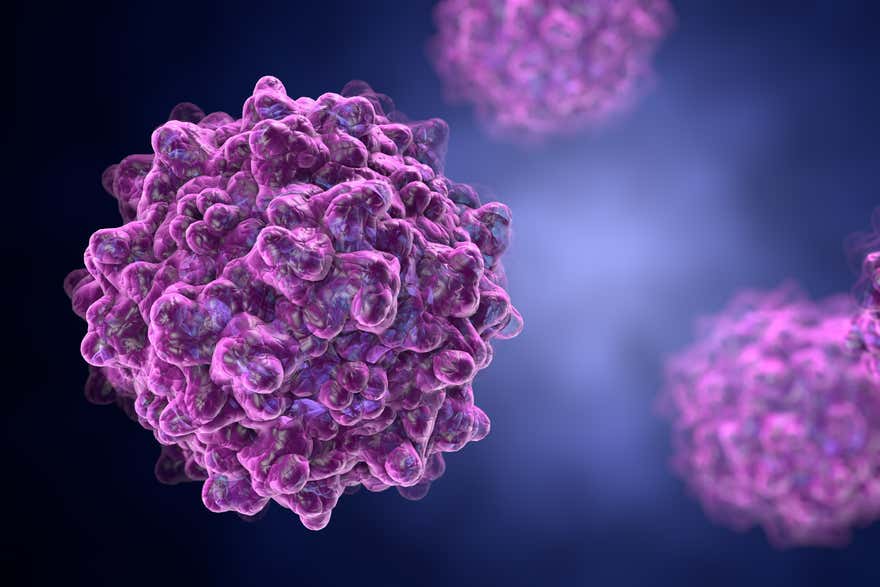

Physical stability of therapeutic proteins in solution

- Products:

- OMNISEC system, MicroCal PEAQ-DSC, MicroCal DSC range, Zetasizer Advance Range, Zetasizer range

- Technology:

- Size Exclusion Chromatography (SEC), Multi-Angle Dynamic Light Scattering (MADLS)

- Industry:

- Academia, Biologics, University, Pharmaceutical