Empyrean range

Multipurpose X-ray diffractometers

Analysis of thin films, surfaces and interfaces

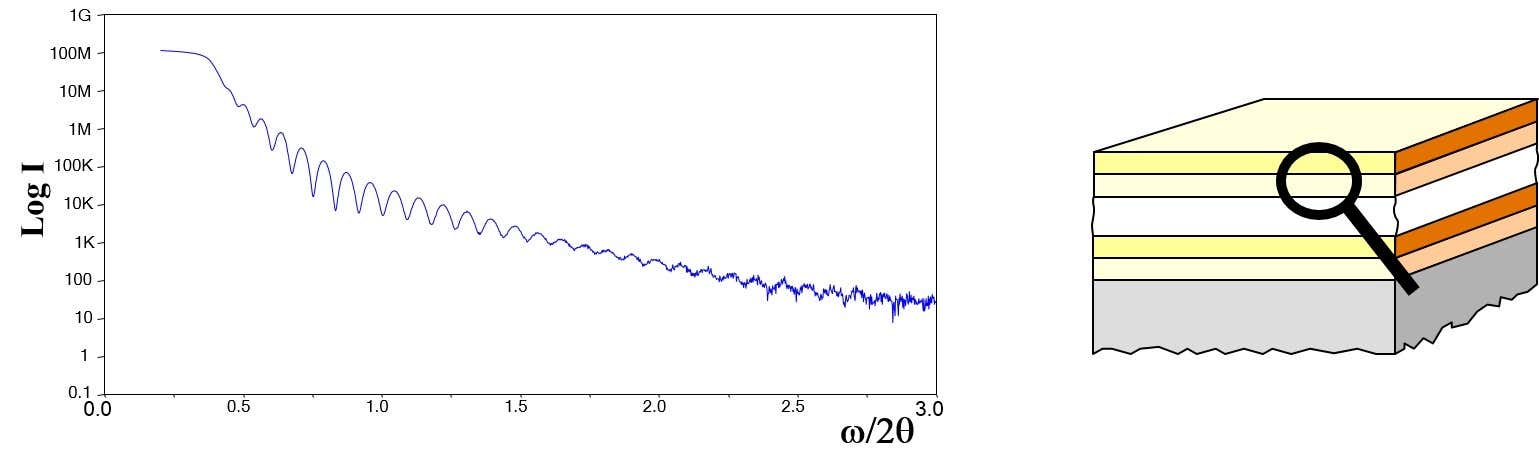

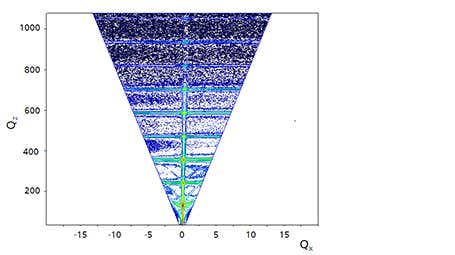

X-ray reflectometry (XRR) is an analytical technique for investigating thin layered structures, surfaces and interfaces using the effect of total external reflection of X-rays.

Reflectometry is used to characterize single and multi-layer structures and coatings in magnetic, semiconducting and optical materials, among others.

In reflectivity experiments, the X-ray reflection of a sample is measured around the critical angle. This occurs around grazing incidence angles.

Below the critical angle of total external reflection, X-rays penetrate only a few nanometers into the sample. Above this angle the penetration depth increases rapidly. At every interface where the electron density changes, a part of the X-ray beam is reflected. The interference of these partially reflected X-ray beams creates the oscillation pattern observed in reflectivity experiments.

From these reflectivity curves, layer parameters such as thickness and density, interface and surface roughness can be determined, regardless of the crystallinity of each layer (single crystal, polycrystalline or amorphous).

Multipurpose X-ray diffractometers

Reflectometry experiments can be performed on Malvern Panalytical's Empyrean systems.

Reflectometry data can be analyzed with a choice of automatic fitting procedures implemented in the Reflectivity software package. Part of Malvern Panalytical's XRD software range, Reflectivity, uses the XRDML data format. By allowing automatic fitting of simulated to experimental specular X-ray reflectivity curves, Reflectivity makes reflectometry, formerly the preserve of highly professional users, available to routine users.

Download the brochure: Semiconductor wafers - Crystalline quality