Material characterization solutions for advanced manufacturing processes and materials

Space travel and human prosthetics have one key thing in common: they’re being revolutionized by Advanced Manufacturing techniques such as additive manufacturing, robotics, and automation. But it’s not just the high-end aerospace and medical sectors that are embracing advanced manufacturing approaches. Many industries, including electronics, automotive, pharmaceuticals, construction, energy and consumer goods sectors are embracing the new possibilities that Advanced Manufacturing approaches offer, such as:

But it’s not just the manufacturing processes that are important – the materials employed are critically important also. This is especially so for processes such as Additive Manufacturing or 3D Printing where structures are built ‘layer by layer’. Here traditional materials and material forms are often not optimised for these processes. So, as well as developing and optimizing the process there is a need for novel materials that are process compatible and give the desired product or component properties.

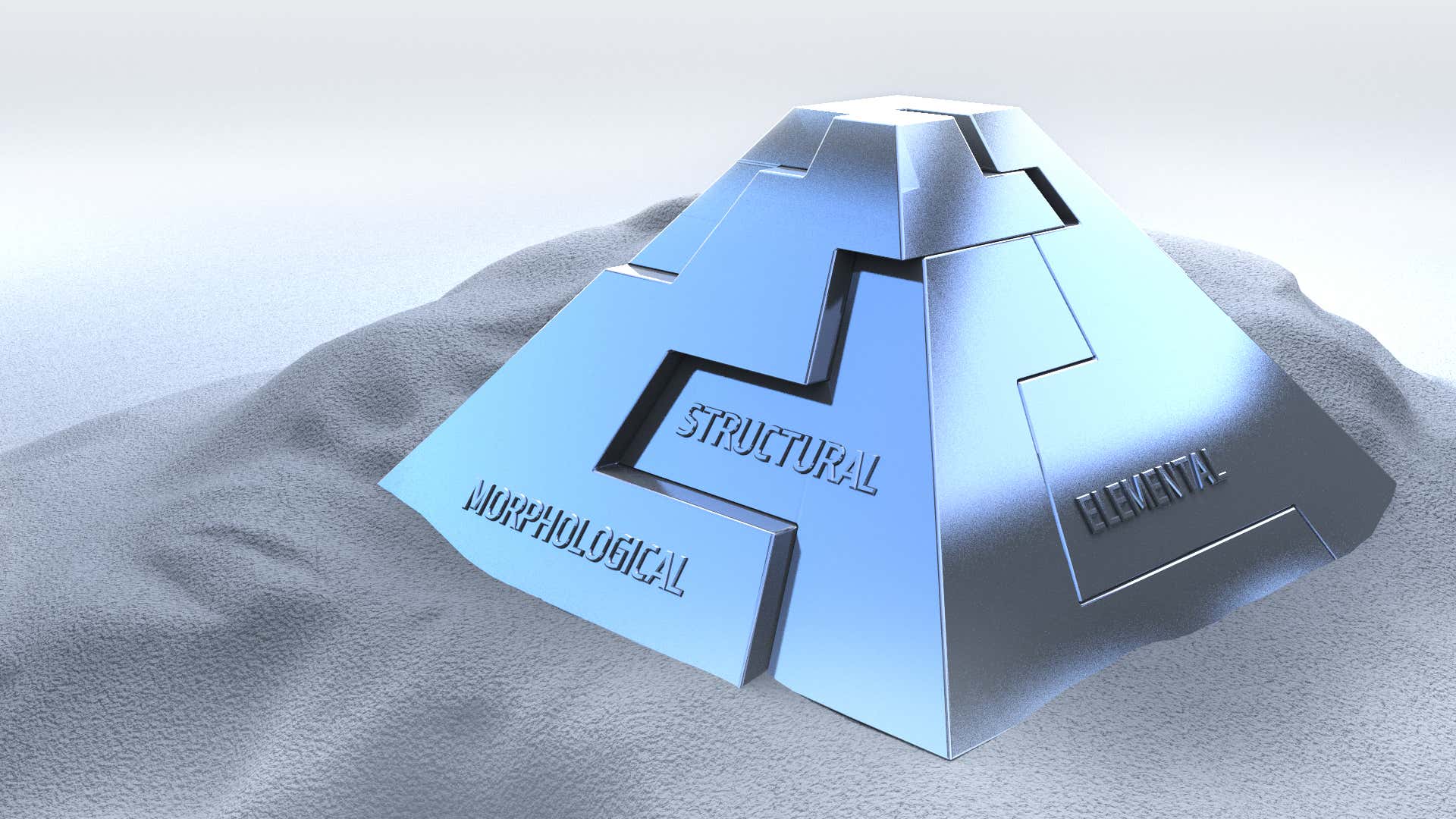

Our material characterization tools for particle size, particle shape, elemental composition, and structural analysis, can help you to develop the next generation materials for Advanced Manufacturing. Our solutions are also used for certifying the quality of your feedstock materials and manufactured products. So, whether you’re working with metals, polymers, composites or ceramics in powder, dispersed or bulk solid form, we have solutions and expertise that can help. Take a look at some of our advanced manufacturing blogs, or explore our pages below.

Our main solutions for particle characterization are the Mastersizer and Morphologi 4, which are benchtop instruments with a high-level of automation. The Mastersizer 3000 uses the technique of laser diffraction to measure particle size distribution and this technique can also be employed on-line using Insitec. Morphologi 4 is an automated imaging system that use a digital camera to capture high-quality 2D images of a dispersed particles and provides particle specific size and shape information.

For elemental analysis we employ the technique of X-ray fluorescence which is available as floor standing (Zetium) and benchtop variants (Epsilon) depending on application requirements. For structural and crystallographic studies X-ray diffraction is our principal solution and is also available as a floor-standing (Empyrean) and benchtop (Aeris) system.

Since introducing the Mastersizer 3000 we have been able to mill to an appropriate particle size to help eliminate issues with the intermediate materials going into a final product

Julie Hart - BASF