Make mining more predictable, sustainable and agile

Improve uptime and lower costs with real-time predictive monitoring

Making mining more predictable, sustainable and agile. Download the leaflet

Download the leafletImprove uptime and lower costs with real-time predictive monitoring

Understanding the changing properties of material streams can save hundreds of thousands of dollars per month. Real-time analysis can help you avoid unnecessary processing of low-grade ore, while ‘data fusion’ from multiple sensors can enable faster, more accurate prediction of changes in process performance that might result in downtime or inefficiency.

Malvern Panalytical will help you benefit from mining automation, by supplying equipment for real-time monitoring, as well as custom-built automated laboratories. This will allow you to move towards a future of ‘intelligent mining’ – a future in which you can manage your operational costs, improve ore extraction methods, streamline distribution, increase worker productivity, and minimize risks to health & safety.

Real-time information on the composition and quality of ores, concentrates, tailings, liquors and wastewater is necessary to react fast to changes in composition and quality, and avoid process equipment downtime.

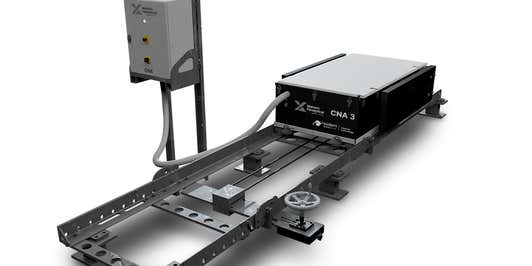

We offer equipment that will enable you to monitor particle size, elemental and mineralogical composition and moisture, either directly in the mine or close to process equipment. We’ll also work with you to develop predictive models based on information from multiple sensors, which will help you maximize productivity, and optimize energy and water consumption.

The mining industry is increasingly seeing a shift from traditional laboratories to automated systems, as a result of the need to enhance sample throughput, and to combine information from multiple sensors, while addressing health & safety requirements.

Our dedicated team of process-automation experts are ready to help you implement laboratory automation in your mining operation; installed in a container, laboratory or directly in a process environment. We’ll work with you to design and deliver a solution that precisely fits your requirements for sampling method, sample preparation processes, sensor type, system backups, uptime, sample throughput and data output. Discover our solutions.