Next-level fusion: Meet all-new FORJ. Find out more

Find out moreImprove recovery rates and process efficiency from exploration to mineral processing

Explore the world of Iron, Base metals, Bauxite, Clay, Coal, Industrial Minerals and Precious Metals in 3D. Interact with our virtual mining world by clicking here and see where and how our world-leading instruments, services and expertise will help you gather, develop, and produce materials with greater precision and shorter lead times than ever.

The shift towards lower grade ore deposits, sustainable energy and volatile market conditions pushes the mining industry towards predictive, sustainable and agile analytical solutions to improve safety, increase operational efficiency and develop new services and business models.

Our mining customers value Malvern Panalytical’s complete offerings of smart technologies. More than 50 years of experience in creating value for all different segments of the mining industry are essential to developing tailored solutions for an optimal and efficient prediction during all steps of your mining process - from mineral exploration to the analysis of final products.

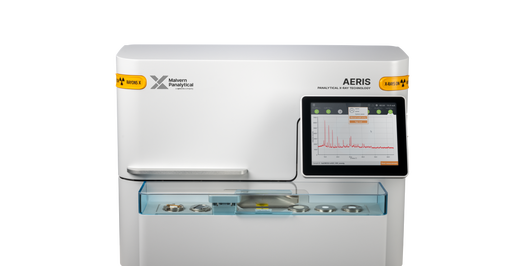

Either direct analysis in the field, on-line sensors to predict ore grades, laboratory equipment or complete automation solutions, our specialists develop together with you the optimal solution tailored to your specific needs.

The focus of the mining industry is shifting towards potential new resources in remote areas as a result of decreasing ore grades. Remote sensing technology is an effective and widely established analytical method for geology and mineral exploration and has proven extremely beneficial by providing access to dangerous or previously inaccessible mineral deposits. Aerial imagery acquired from hyperspectral and multispectral imaging sensors is applied to geological surveys, alteration zones mapping, and geomorphology applications. Important aspects of these studies are supported by collecting ground truthing data with portable spectrometers. Data from highly portable field instruments is compatible with popular image analysis software, allowing the creation of spectral libraries tailored to a specific application.

Portable mineralogical and elemental analyzers enable exploration geologists to safely obtain immediate information in the field or mine and to define geological boundaries in real-time. Rock chip and core analysis directly on the drilling rig allows on-the-spot decisions for optimal grade block definition, mine planning and efficient use of your drilling budget.

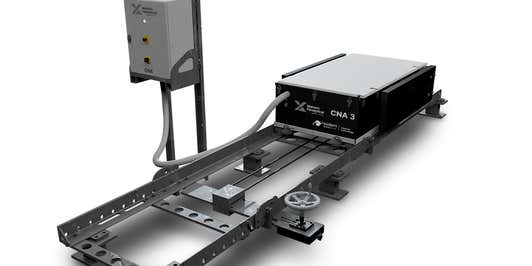

Malvern Panalytical’s cross-belt analyzers allow direct and safe detection of ore variations as well as fast counteractions on changing ore composition. Early and accurate ore blending and sorting saves millions during downstream processing. It ensures a homogenous output towards the beneficiation plant and avoids the processing of low grade ore or waste.

Our solutions can be employed for continuous, non-contact monitoring of elemental and mineralogical composition as well as the prediction of process relevant parameters in a large range of mining applications such as iron, bauxite, copper, nickel or coal.

Reducing the cost of mineral extraction and energy consumption, milling your product to the correct grade size and frequent monitoring of the mineralogical and elemental composition are areas where we can partner with mining companies during ore processing. Tailored to the specific need of your process we offer real-time monitoring equipment as well as bespoke laboratory automation solutions. Together with our customers, we develop predictive models ensuring fast counteractions to enable constant and optimal mineral processing conditions.

Reuse, recycling and recovery of mine rejects is an important factor for operating a mining business in a sustainable way and to protect against the environmental impact of mining. Dedicated analytical solutions for elemental analysis, particle size and shape characterization, monitoring zeta potential and characterization of clay minerals can help to reduce the negative effects of mining on the environment.