Precious Metal Testing

Reduce cut-off grades and increase recovery for gold, silver and platinum group metals (PGM)

Comprehensive turnkey solutions for elemental analysis of all Rare Earth Elements (REEs). Download now

Download nowReduce cut-off grades and increase recovery for gold, silver and platinum group metals (PGM)

Precious metals are simply rare, naturally occurring metallic elements. They have high economic value because of their rarity, aesthetic qualities, and usefulness in industrial applications. Precious metals play a pivotal role in the mining industry, serving as coveted resources with diverse applications across various sectors. There are several precious metals. These are the most commonly known:

There are other precious metals found in the platinum group metals (PGM) of the periodic table, namely palladium (Pd) and rhodium (Rh). The mining of these precious metals demands intricate extraction techniques and often occurs alongside other valuable minerals, driving innovation and technological advancement in the mining sector.

Several analytical techniques are used throughout the precious metals mining process to obtain different types of measurements:

Malvern Panalytical offers instruments that meet the industry’s analytical needs at all stages of the precious metals mining process. The following explains how our precious metal analyzer instruments apply the above technologies to specific mining activities:

Taken together, Malvern Panalytical instruments deliver the insight needed to extract the maximum value from all stages of precious metals mining. The comprehensive suite of technologies in our instrument family provides a 360° analysis of the entire process, meaning that your instruments not only tell you what is going on, but achieve goals as diverse as making processes more efficient, reinforcing sustainable practices, increasing profits, and informing strategic decisions.

Easy elemental monitoring for activated carbon

Precious metals analysis poses several challenges due to their unique properties and applications. The greatest challenge in the precious metals mining industry is to produce consistently high-grade concentrates at maximum recovery rates. Ensuring the accuracy and reliability of measurements is crucial, especially considering the high value and economic significance of precious metals. The grade of a concentrate is directly related to the process conditions, mineralized block, gold distribution, and diluents such as sulfides, graphite, clays, and organic matter. Overall, overcoming these challenges in precious metals analysis requires a combination of advanced instrumentation, rigorous methodologies, and expertise in analytical techniques.

Malvern Panalytical provides analytical solutions for monitoring geological, mineralogical, and metallurgical parameters. These can be used to optimize grade block definition and mine planning, including the profitability of precious metal mining operations. Our experts can tailor system designs in conjunction with industry specialists of all kinds.

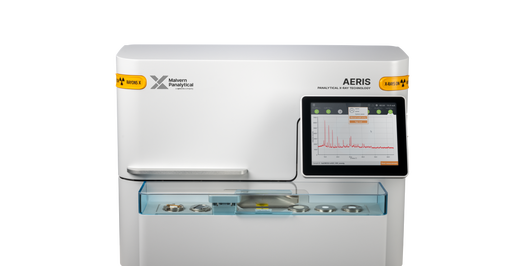

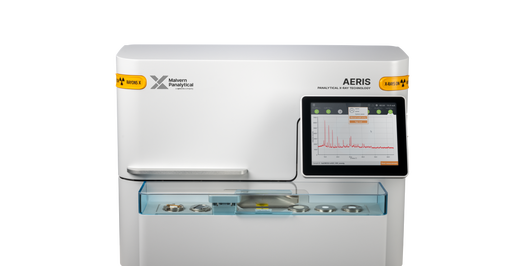

With ore deposits becoming increasingly depleted in high-grade mineral content, mining operations are compelled to process larger volumes of lower-grade material to maintain production levels. XRF technology offers a rapid and non-destructive solution by providing elemental analysis of ore samples, enabling miners to swiftly assess the presence and distribution of precious metals such as gold, silver, platinum, and palladium. Malvern Panalytical benchtop X-ray fluorescence spectrometers can detect gold concentrations as low as 1.5 parts per million in loose powders within 10 minutes.

Meanwhile, NIR spectroscopy offers insights into mineral composition and alteration, aiding in the identification of valuable minerals and gangue minerals. Malvern Panalytical offers portable precious metal analyzers that enable exploration geologists to safely and immediately obtain information in the field or mine, such as identifying precious metal-bearing mineralogical domains and predicting optimal processing conditions.

Our solutions based on near-infrared (NIR) spectroscopy deliver results at the touch of a button. They can also track geochemical conditions using the Al-OH scalar or the Illite Spectral Maturity (ISM) scalar, an indicator of a deposit’s thermal maturity.

By integrating these advanced analytical techniques into exploration workflows, mining companies can optimize resource allocation, streamline processing strategies, and mitigate risks associated with declining ore grades and complex mineralogy, ultimately enhancing efficiency and profitability in the precious mineral industry.

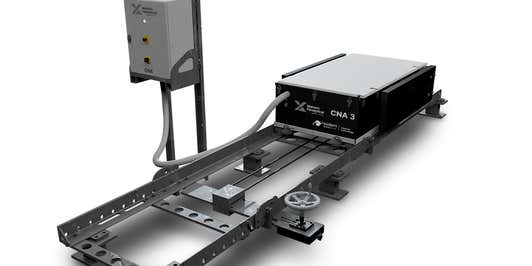

Consistent ore quality is essential for processing precious metals minerals in the concentrator. As the ore passes along a conveyor belt, real-time elemental monitoring sorts the ore based on proxy minerals.

Real-time elemental monitoring of ore as it moves along a conveyor belt allows precious metal ores to be sorted based on proxy minerals. Different ore grades can be blended into a consistent feed. A mine can effectively increase the capacity of its concentrator by eliminating the low-grade ore feed.

Many older gold tailing facilities have attracted the interest of mining companies because the tailings retain impressive mineral values, raising the possibility of reprocessing the tailings to generate additional revenue. Tailings dams also provide opportunities for environmental remediation. Malvern Panalytical’s CNA instrument family range provides the tools to monitor the composition of tailings and residues on-line, helping companies to make reprocessing more efficient.

Ore streams can be modified depending on the outcome desired of the separation and concentration stages. To modify the ore stream, an on-line elemental analyzer is used to identify mineralogical domains and monitor mineral composition at each step of the process. The mix of reactants and reagents can then be adjusted based on the mineral composition. When the process is running optimally, recovery rates are increased and costs of energy and consumables are reduced.

X-ray diffraction is an easy, fast, and reliable tool for precious metal testing and quantifying mineral content – even of complex ores. Our industrial diffractometers are designed to operate in harsh industrial environments with dust protection and temperature control features.

The instruments can also be automated for autonomous operation in difficult environments. Need advice? Specialists in the Malvern Panalytical Process Automation Solutions (PAS) group can explore tailor-made automation solutions to meet your needs.

Malvern Panalytical not only offers solutions for mineral quantification but also provides comprehensive support throughout the mining value chain. For example, we provide statistical tools that enable the direct prediction of process parameters, facilitating short feedback loops to enhance plant operations.

Have something more specific in mind? Our dedicated specialists have expertise in digital solutions and process optimization to design a bespoke solution.

Preg-robbing occurs in gold extraction. It occurs when certain minerals and ore components have a strong affinity for gold cyanide complexes, absorbing the gold and making it unavailable for extraction. Preg-robbing materials include carbonaceous materials, organic matter, and other minerals. It is a well-known challenge in the flotation and leaching of precious metal ores.

The Malvern Panalytical Zetasizer and Zetium instruments can monitor the mineral and elemental composition as well as zeta potential. Processors can take immediate corrective action to prevent preg-robbing and increase precious metal recoveries.

Increase your process efficiency and recovery rate

A common activity in precious metal ore processing is the analysis of the Au concentrations absorbed on the surface of activated carbon. This is a critical measure of the efficiency of carbon in pulp (CIP) and carbon in leach (CIL) processes.

Operators can significantly improve plant efficiency by measuring the gold in the stripping solution, quickly and easily determining when the solution is depleted of gold. Our benchtop XRF solutions provide a simple, low-cost, and at-line analytical technique for monitoring the elemental composition of such solutions. Non-technical operators can obtain results in minutes without the need for special sample preparation, sample conditioning, or technical expertise.

Charge make-up refers to the composition of the raw materials processed in refineries and smelters. To achieve the most efficient refining and smelting process, the charge make-up needs to be perfected for each gold deposit. This requires detailed knowledge of each deposit’s mineral composition.

One important component is the iron that is bound in the minerals magnetite (Fe3O4) and hematite (Fe2O3), which require different amounts of reactant to compensate. Whereas elemental analysis previously could only determine the concentration of the total iron content, X-ray diffraction can now easily determine the amounts of both phases. With this knowledge, furnace conditions can be optimized, resulting in huge energy savings.

Continuous slag analysis using our XRD solutions significantly improves the effectiveness of the melt by monitoring crystalline phases and amorphous content. In addition, gold ingots can be traced back to their crucible and casting mold by identifying the unique silicon carbide and graphite markings on the ingot surface. This provides traceability and control in the ingot production process.

All gold recovery processes generate waste material that must be disposed of safely. The primary considerations for safe disposal are environmental regulations, health and safety regulations, and permitting requirements. Taken together, these regulations prevent pollution of the environment, protect workers and communities, and ensure that disposal takes place in an orderly fashion.

As a result, rejects of precious metal mining must be carefully monitored to avoid legal issues and ensure sustainable mining. Our dedicated analytical solutions ensure safe waste management in accordance with international standards and regulations by:

Our mining customers value Malvern Panalytical’s complete range of smart technologies. From mineral exploration to final product analysis, we have over 50 years of experience in developing tailored solutions for all stages of your mining process.

We have the infrastructure and expertise to support the entire mining value chain, from exploration and extraction, to processing, waste management, and shipping. Leverage the expertise of our dedicated scientists and engineers in our Application Competence Centers. Or, if you are looking to automate your processes, our Process Automation Solutions (PAS) group and digital group can support your goals.

Developing and customizing solutions with our customers is second nature to us. When the hard work is done, our specialists are still there to help. Digital features such as Smart Manager and My Customer Support Portal centralize information and enable remote monitoring capabilities, so proactive maintenance stays proactive, and extra support is quickly available if needed.