Coal mining, extraction and beneficiation

Increase combustion efficiency and save on coal processing costs

Comprehensive turnkey solutions for elemental analysis of all Rare Earth Elements (REEs). Download now

Download nowIncrease combustion efficiency and save on coal processing costs

Independent from the use for power plants, steel making or anode production, coal mining and beneficiation must ensure consistent quality of coal under sustainable conditions.

Malvern Panalytical delivers tailored analytical solutions to control ash percentage in coal, to monitoring deleterious elements and moisture and to predict graphitization or calorific value in coal mines and power plants. Either direct analysis in the field, on-line sensors to predict coal grades, laboratory equipment or complete automation solutions, Malvern Panalytcial’s specialist develop together with process engineers, laboratory- and quality managers the optimal solution tailored to your specific needs.

Mines and beneficiation plants benefit directly from quality control and optimization of the coal loadout. Total ash, ash composition, sulphur, moisture content and calorific value are usually front-rank information to increase blending process, combustion efficiency and value of the coal.

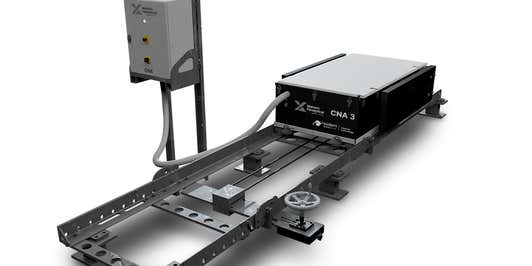

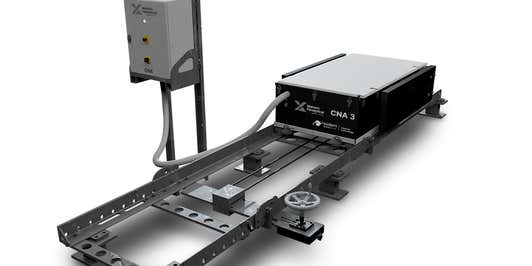

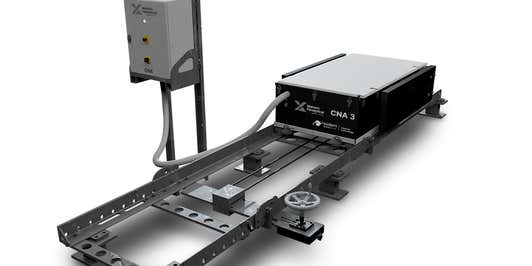

Malvern Panalytical’s solutions for real time monitoring of coal on conveyor belts (elemental and mineralogical) with its fast feedback loops enable fast counteractions on changing coal composition directly in the mine and effective blending. Control of the moisture content on the conveyor belt (NIR) together with accurate monitoring of the composition of coal before shipment guaranties constant quality to avoids penalties.

Beneficiation of coal is only economical if the benefits realized in the power plants are greater than the overall costs for coal beneficiation. Main drivers for optimizing coal feed for power plants are:

This requires accurate monitoring of the moisture, mineral content, particle size, graphitization and calorific value of the coal before, during and after the beneficiation process.

We developed solutions based on laser diffraction for monitoring the particle size of coal in real-time as well as in a laboratory. The mineralogical composition of the mineral matter and/or fly ash can be analysed easily and fast with X-ray diffraction (XRD). In addition to the phase content XRD can also provide information about the degree of the graphitization and crystallite size of coal.

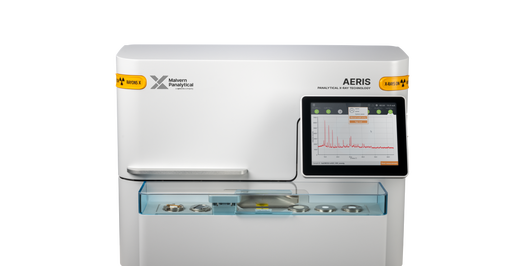

Our benchtop X-ray fluorescence spectrometers for elemental analysis are portable and easy to use in a production environment.

For on-line monitoring directly on the conveyer belt, we offer solutions for:

To save capital and operating costs of power plants, efficient combustion requires constant monitoring of coal feed and ash. The main technical benefits of process control in power plants are:

In addition, real-time sensors for ash monitoring based on near infrared spectroscopy (NIR) enable the prediction of boiler efficiency and fly ash output of power plants. The accurate analysis of the elemental composition of fly-ash in the laboratory with dedicated X-ray fluorescence (XRF) ensures an optimal quality to sell it to the building materials industry.

Environment protection

Sustainability and protection of the environment are the key focus for power plants. Our solutions to controlling toxic emissions through elemental analysis, such as sulphites and other volatile compounds present in the coal, are proven to be the perfect tool to analyse according to international norms and regulations.