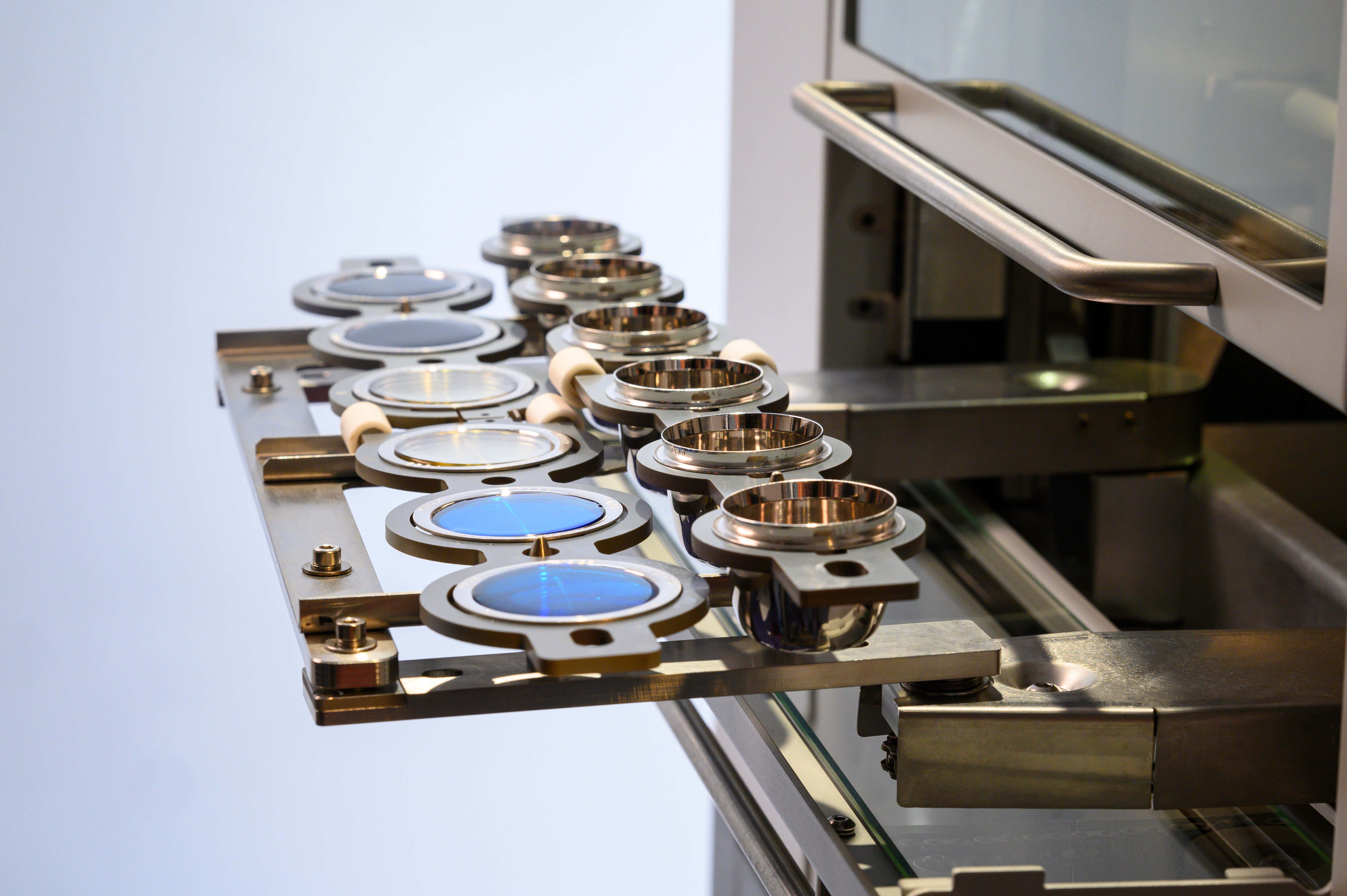

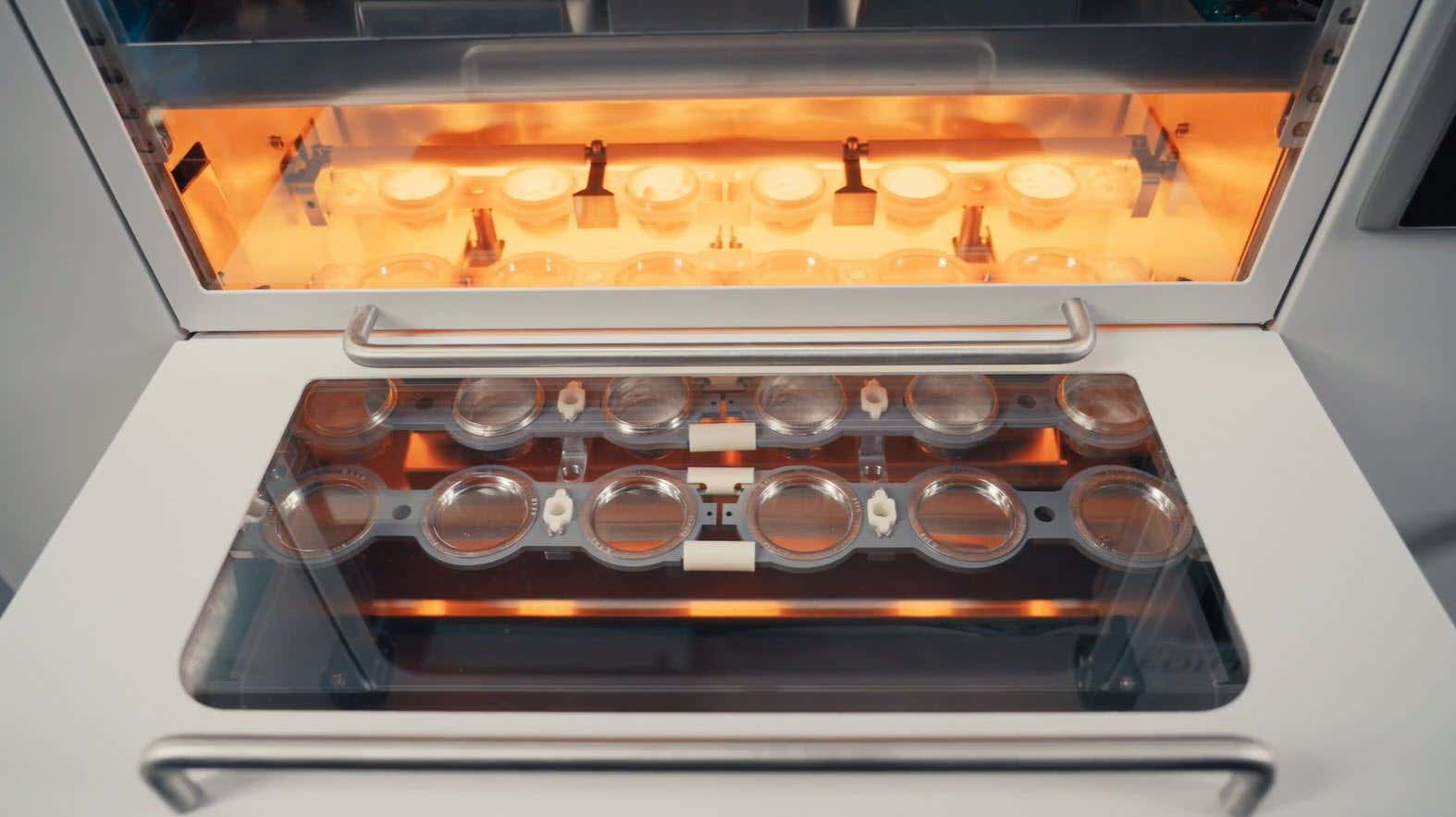

Tray loader

Upgrade your sample preparation with optional features

With the Tray Loader, FORJ™ helps maximize your productivity – allowing you to load up to 12 samples at a time and enabling a fusion cycle to start without the presence of an operator.

The result? No time wasted in the heating chamber, up to 25% productivity increase and significantly lower operation time.