Micromeritics TriStar II Plus

High throughput BET surface area analyzer

Unlock material insights with precise gas adsorption analysis

Gas adsorption is a fundamental process where gas molecules adhere to the surface of solid materials. This phenomenon is pivotal in various scientific and industrial applications, including material science, catalysis, and environmental technology.

Gas adsorption can be broadly classified into two distinct types: physisorption and chemisorption, each driven by unique interaction mechanisms. These processes provide critical insights into material properties, enabling scientists and engineers to analyze surface area, porosity, and catalytic behavior.

Micromeritics gas adsorption analyzers are ideal for characterizing materials' surface area and pore structure. These instruments measure the amount of gas adsorbed under controlled pressure and temperature conditions, providing detailed insights into material porosity, pore size distribution, and specific surface area. Such data is essential for industries like pharmaceuticals, battery materials, and adsorbent development.

For chemisorption studies, Micromeritics chemisorption analyzers are engineered to evaluate the chemical reactivity and active surface sites of materials. These systems measure the strength and quantity of gas-surface interactions, helping to characterize catalysts, monitor surface reactions, and optimize catalyst performance in processes like hydrogenation, cracking, and reforming. This capability is invaluable in catalysis research and process development for energy and chemical industries.

Micromeritics' advanced technology ensures reproducible results and robust data, empowering researchers to fully understand and optimize material properties for their specific applications.

The Brunauer-Emmett-Teller (BET) theory is a widely adopted method for measuring the specific surface area of materials. Typically, nitrogen gas (N₂) is used as the adsorbate due to its favorable interaction with most surfaces. By analyzing the amount of gas adsorbed at various pressures, the BET equation facilitates the calculation of the material's surface area.

![[Gas adsorption - bet surface area diagram.jpg] Gas adsorption - bet surface area diagram.jpg](https://dam.malvernpanalytical.com/68a33efb-2875-43f8-9f37-b26e00a51333/Gas%20adsorption%20-%20bet%20surface%20area%20diagram_Original%20file.jpg)

|

![[Gas adsorption - bet surface area diagram - linearised graph.jpg] Gas adsorption - bet surface area diagram - linearised graph.jpg](https://dam.malvernpanalytical.com/daba6e91-d18f-44fb-ac92-b26e00a51180/Gas%20adsorption%20-%20bet%20surface%20area%20diagram%20-%20linearised%20graph_Original%20file.jpg)

|

| The BET surface area of a material is calculated from the monolayer capacity which is the volume of the first single layer of gas molecules or atoms adsorbed on the surface. | The BET equation is linearized to conveniently calculate the monolayer capacity from the slope and y-intercept of the BET transform plot, which must achieve a sufficiently high correlation coefficient for a valid BET calculation, which is typically 0.999. |

Gas adsorption enables characterization and structural analysis of material porosity. As gas pressure increases, pores within the material begin to fill. This process starts with smaller pores and progresses to larger ones until all are saturated. Overall, gas adsorption is applicable to pores ranging from ~0.35 nm to ~400 nm in diameter. Once details of the isotherm curve are accurately expressed as a series of pressure vs quantity adsorbed, a number of different methods (theories or models) can be applied to determine the pore size distribution.

| Classification | Size | Typical Calculation Models |

|---|---|---|

| Micropore | <2 nm | Density Functional Theory (DFT) M-P Method Dubinin Plots (D-R, D-A) Horvath Kawazoe (H-K) t-plot (total micropore area) |

| Mesopore | 2-50 nm | Barrett, Joyner, and Halenda (BJH) Density Functional Theory (DFT) Dollimore-Heal (DH) |

| Macropore | > 50 nm | Barrett, Joyner, and Halenda (BJH) Density Functional Theory (DFT) Dollimore-Heal (DH) |

| *Special Considerations | >400 nm | For pores exceeding 400 nm, other techniques such as mercury intrusion porosimetry (link to page) are employed. This technique offers insights into larger pores, typically starting from 3 nm up to 1100 µm |

Gas adsorption analysis plays a critical role across diverse industries by providing detailed insights into material properties, enabling the optimization of processes and products. Below are key applications and how they benefit various sectors:

The performance of catalysts is heavily influenced by their surface area, porosity, and active site availability. Gas adsorption techniques, such as chemisorption, allow for the precise characterization of catalyst surfaces, helping researchers evaluate properties like dispersion, metal-support interactions, and adsorption strength. This data is crucial for optimizing reaction efficiencies in processes like chemical synthesis, petroleum refining, and emissions control.

In drug development, the surface area and porosity of pharmaceutical powders directly impact solubility, dissolution rates, and bioavailability. Gas adsorption instruments are used to analyze these properties, ensuring that drug formulations are designed for optimal performance, stability, and delivery. This is particularly important for inhalable drugs and controlled-release formulations.

For energy storage technologies, such as lithium-ion and solid-state batteries, electrode materials with high surface areas and controlled porosity are essential for enhancing charge storage and ion transport. Gas adsorption analysis enables the precise evaluation of these material characteristics, contributing to the development of higher-capacity, longer-lasting, and more efficient batteries.

Gas adsorption is key to studying materials used for pollutant capture and removal, such as activated carbons and zeolites. By analyzing adsorption capacity, pore structure, and gas-solid interactions, researchers can optimize materials for capturing greenhouse gases, volatile organic compounds, and heavy metals. This technology supports cleaner air, water, and sustainable industrial practices.

Gas adsorption analysis is an indispensable tool for advancing material research and innovation across these industries, offering accurate, actionable data for product development and process optimization.

Mercury Intrusion and Capillary Flow

Physisorption and chemisorption are the primary types of gas adsorption. The differences are highlighted in the table below:

| Physisorption (Physical Adsorption) | Chemisorption (Chemical Adsorption) |

|---|---|

| Non-selective | Selective |

| Weak Interactions (van der Waals) | Strong Interactions (chemical bonds) |

| Lower Energy | Higher Energy |

| Reversible | Irreversible & Reversible |

At Malvern Panalytical, we provide advanced solutions for gas adsorption analysis, incorporating Micromeritics’ industry-leading instruments to deliver precise and reliable data for material characterization. These systems are designed to address diverse applications, from basic surface area measurements to in-depth porosity and catalytic analyses.

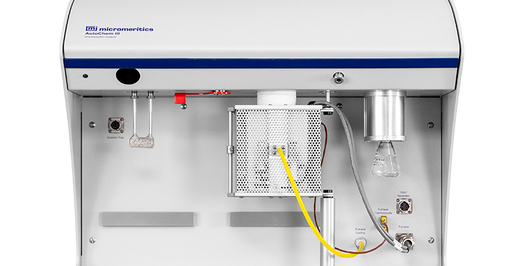

High throughput BET surface area analyzer

The TriStar II Plus is a versatile, three-station instrument ideal for routine surface area and porosity measurements.

It employs the Brunauer-Emmett-Teller (BET) theory to determine specific surface areas, and other gas adsorption models to determine pore size distributions, making it suitable for applications in material science, pharmaceuticals, and adsorbent development.

High performance gas adsorption

The 3Flex instrument is a flexible, multi-station system for high-resolution physisorption and chemisorption measurements.

Its high precision and advanced data analysis capabilities make it ideal for research in catalysis, energy storage, and environmental science.

A catalyst characterization laboratory in a single analytical instrument

Specifically engineered for chemisorption and temperature-programmed analysis studies, the AutoChem III provides detailed insights into catalytic activity, adsorption strength, and reaction mechanisms.

This instrument is essential for optimizing catalyst formulations and evaluating surface reactions under simulated operating conditions.

Rapid and precise surface area analysis

A rapid and cost-effective instrument, the Gemini is designed for surface area and porosity measurements.

Its user-friendly design makes it an excellent choice for quality control environments or routine laboratory use.

Accelerated surface area and porosity

A high-performance gas adsorption analyzer, the ASAP 2020 Plus delivers detailed surface area, porosity, and chemisorption data.

It’s designed for advanced studies requiring comprehensive pore structure characterization or the evaluation of active sites in catalysts.

Surface area and porosimetry system

Instruments such as the ASAP 2460 and ASAP 2425 provide unparalleled resolution for high-throughput analyses of microporous materials.

These are critical for applications like carbon capture, hydrogen storage, and adsorbent development.

With these solutions, we empower researchers and industry professionals to gain deeper insights into material properties, enabling the development of innovative products and efficient processes. Malvern Panalytical’s expertise, combined with Micromeritics’ proven technology, ensures reliable results and outstanding support for your gas adsorption analysis needs.