FlowPrep

The Micromeritics FlowPrep lets you choose the most suitable gas, temperature, and flow rate for your application and sample material.

Looking for more information?

To request a quote, more information or download a brochure select an option below.

Surface area and pore volume are important physical properties that influence the quality and utility of many materials and products. It is critical that these characteristics are precisely determined and controlled. Similarly, an understanding of surface area and pore volume is often key in understanding the formation, structure, and potential application of many natural materials.

The Micromeritics’ Gemini surface area analyzer rapidly and reliably produces accurate and repeatable surface area and pore volume results. Low cost, speed, simplicity of use, reliability, and ruggedness have earned the Gemini a place in laboratories worldwide as an essential tool in research and quality control environments.

Superior data presentation capabilities

Gemini analyzers can be operated from a keypad by way of embedded software or from a computer using the more-powerful and versatile Gemini Windows optional software.

The embedded software includes:

The easy-to-use Gemini Windows 7 interface enhances the capabilities to plan, launch, and control the analysis. You can collect, organize, archive and reduce raw data, and store standardized sample information and analysis conditions for easy access during later applications. Finished reports may be generated to screen, paper, or to files in various formats. Features include cut-and-paste graphics and tables, scalable-and-editable graphs, and customizable report formats. Using computer control, you can operate up to four Gemini analyzers simultaneously from a single computer.

Gemini Windows® Features

Gemini Windows software provides additional features not included with the embedded software. Features such as:

Confirm™ software is available with the Gemini, which addresses the many requirements specified by 21 CFR Part 11 validation, security, audit trails, reporting, and more.

Windows software with all Micromeritics’ gas adsorption instruments contains the following reports:

Isotherm Reports

Isotherm modeling and surface area

Standard isotherm models

Classic models for mesopore volume, area, and distribution

Classic models for micropore distribution

Density Functional Theory for pore size modeling

Density Functional Theory for surface energy

* BJH and Dollimore-Heal require the Gemini VII 2390t to take full advantage of pore size reports based upon the desorption isotherm

The Gemini VII 2390a model is ideal for rapid and accurate surface area determinations by single-point and multipoint BET and Langmuir methods. In addition, it provides standard methods for total micropore volume using the t-plot method. This model features the ability to determine the statistical thickness surface area (STSA) of carbon blacks (refer to ASTM D6556, ISO/DIS 18852.2, or ISO/CD 4652-2/3).

The Gemini VII 2390p model provides additional precision with the addition of a saturation pressure (Po) tube that allows the system to monitor the saturation pressure of the adsorptive on a continuous basis during an analysis using a dedicated pressure transducer. This design feature permits a rapid measurement of the adsorption isotherm to near-saturation, as well as the determination of pore size distribution.

The Gemini VII 2390t model has all of the facilities of the 2390p with the addition of a larger dewar and longer sample tubes for extended analysis times. This provides the additional capability to measure the complete adsorption-desorption isotherm and perform pore size distribution measurements by BJH or DH using up to 1000 data points.

| Surface area | From 0.1 m², total; From 0.01 m²/g, specific |

|---|---|

| Pore Volume | 4 x 10-6 cm³/g |

| Pressure measurement range | 0 to 950 mm Hg |

|---|---|

| P/Po resolution | <10-4 |

| Relative pressure range | 0 to 1.0 P/Po (adsorption only) |

| Pressure resolution | <0.1 mmHg |

| Accuracy and linearity (transducer manufacturer’s specification) | Better than ± 0.5% Full Scale |

| Temperature | 10 to 35 °C (50 to 96 °F) operating; 0 to 50 °C (32 to 122 °F) non-operating |

|---|---|

| Humidity | 20% to 80% relative, non-condensing |

| Adsorbate | Optimized for nitrogen in a liquid nitrogen sample bath; Gemini may be used with non-corrosive adsorbate gases having vapor pressures at both room and bath temperatures that are acceptably high relative to the resolution of the 1000-mmHg pressure transducer. Typically, oxygen, argon, carbon dioxide, butane, methane, and other light hydrocarbons will produce useful data above absolute pressures of a few mmHg. Helium inlet also provided. |

|---|

| Vacuum system | Vacuum source achieving 20 x 10-3 mmHg (or better) at the instrument inlet; having a device to reduce oil vapor backstreaming is recommended. The system must have an anti-suckback valve to prevent oil from being admitted into the Gemini should there be a power failure. |

|---|

| Standard tube | Gemini VII 2390a and 2390p: 0.95 cm (3/8 in.) outside diameter by 15.5 cm (6.1 in) with 6.5 cm³ of volume. Sample capacity is approximately 2.0 cm³

Gemini VII 2390t: 0.95 cm (3/8 in) outside diameter by 20.5 cm (8.1 in.) with 8.9 cm³ of volume. Sample capacity is approximately 2.0 cm³ |

|---|---|

| Dewar | ~ 8 hours; Gemini VII 2390a and 2390p

~ 24 hours; Gemini VII 2390t |

| Voltage | 85 to 265 VAC |

|---|---|

| Frequency | 50/60 Hz |

| Power | 150 VA, operating, max. plus vacuum pump |

| Height | 59 cm (23 in); Gemini VII 2390a and 2390p; 74 cm (29 in); Gemini VII 2390t |

|---|---|

| Width | 40 cm (16 in) |

| Depth | 51 cm (20 in) |

| Weight | 32 kg (70 lbs); Gemini VII 2390a and 2390p; 35 kg (78 lbs); Gemini VII 2390t |

External sample preparation is recommended to provide optimal analysis throughput and quality of measurement. All basic sample preparation systems are designed with six independent stations so samples can be prepared as they become available, so preparation does not limit analytical throughput.

The Micromeritics FlowPrep lets you choose the most suitable gas, temperature, and flow rate for your application and sample material.

The Micromeritics VacPrep features six degassing stations, and a choice of vacuum or gas flow preparation on each of the six stations.

Specifically developed for conveniently filling Dewars for gas adsorption instruments, but also can be used for other cryogen applications.

The clear advantages of the Gemini’s capabilities come from its unique and innovative design. The Gemini system is both reliable and accurate, with an easy-to-use operating system including intuitive reporting.

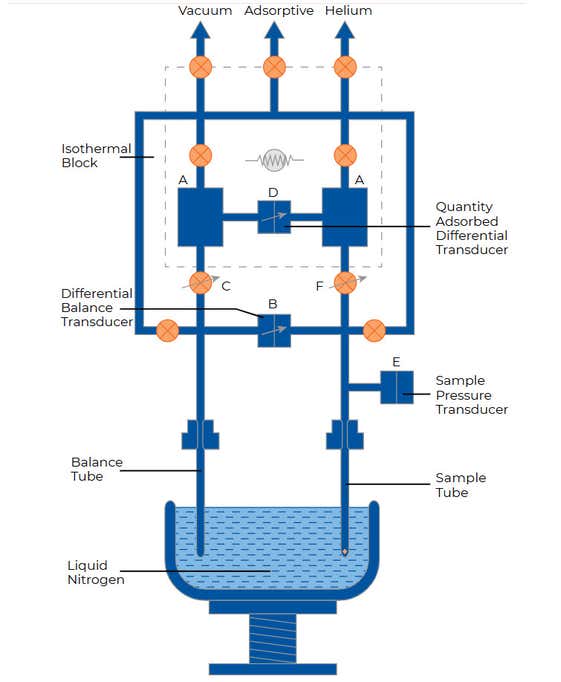

Gemini utilizes a unique adaptive rate dosing algorithm and is a special case of the static volumetric technique. Speed and sensitivity are unsurpassed by other static volumetric instruments.

Micromeritics invented the balance tube design, which negates freespace errors introduced by thermal gradient variations or by initial mismeasurement of free space. The Gemini permits low surface area measurements without requiring krypton and the use of a servo valve controls the rate of gas flow into the sample tube to accurately attain target pressures without pressure overshoot.

The sample controls the rate at which the gas is delivered thus accelerating delivery of the analysis gas. This results in a surface area analyzer that is as fast as the physics of adsorption allows. How-to videos provide on-screen instruction on instrument operation reducing training time for new users. Easy-to- follow installation videos and system verification tests ensure optimum performance and reliability.

Three choices of software control:

Version number:

Please contact support for the latest software version.

Low cost, fast, easy-to-use surface area and pore volume analyzer. Find out why the Gemini is an essential research tool in quality control laboratories worldwide.