Overview

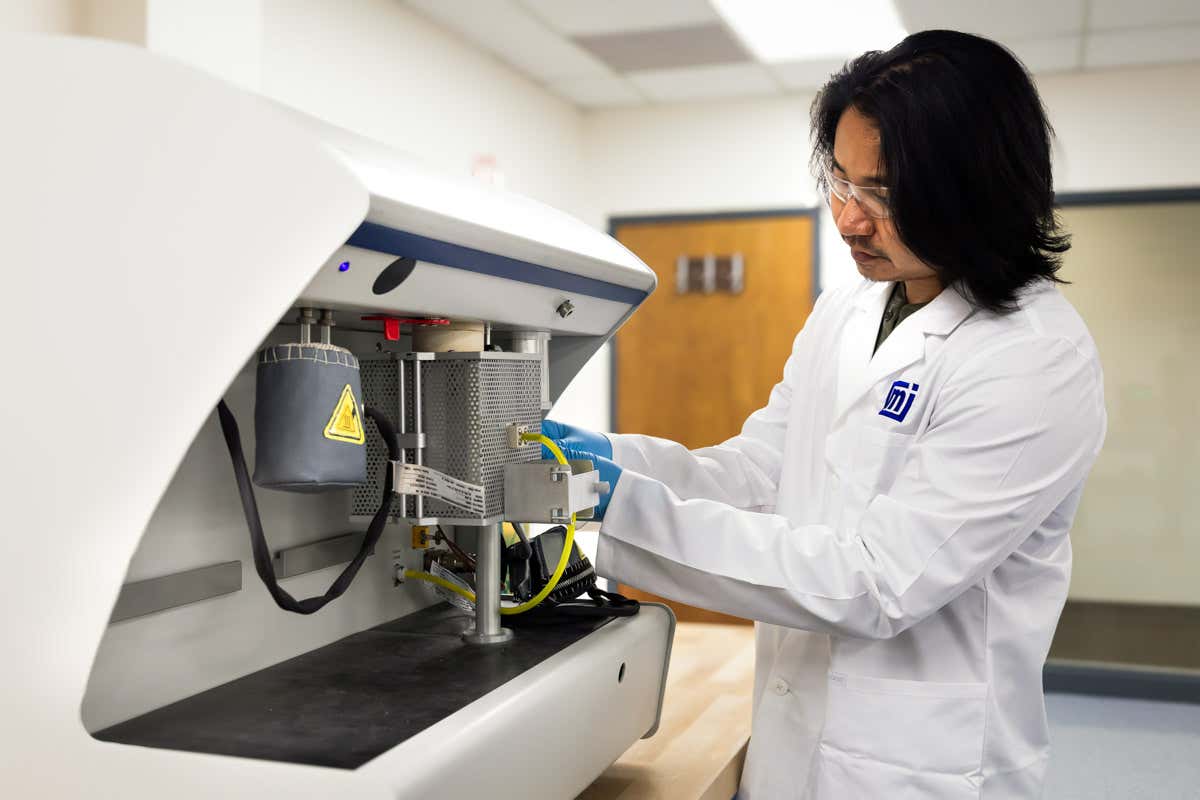

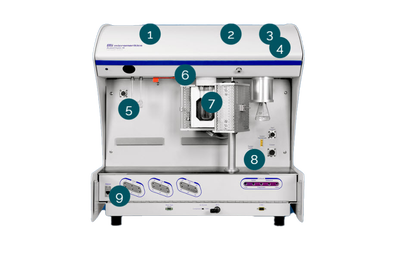

The AutoChem from Micromeritics is the most widely used and highly cited system for catalyst reactivity characterization because it is also the most automated, highly accurate system for chemisorption and temperature-programmed reactions.

The all-new AutoChem III meets and exceeds that performance with a design that will save you hours a day, make the most sensitive, reproducible measurement, and enhance operator safety.

|

|

Features

-

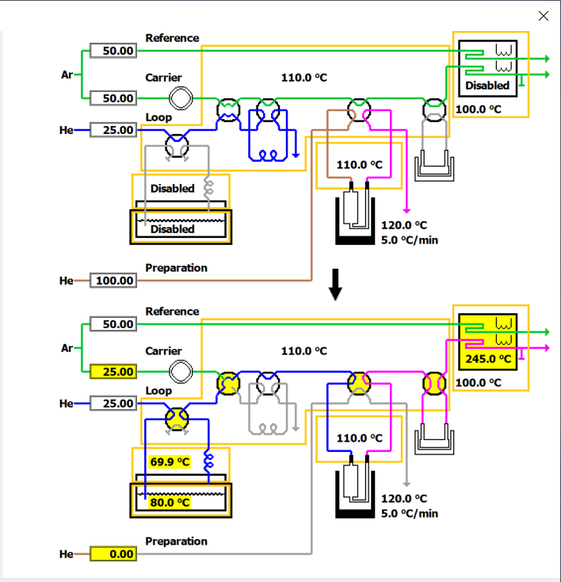

Internal gas temperature control in four separate zones prevents condensation during studies with vapor and improves overall signal stability.

-

The lowest internal gas volume provides the highest peak resolution and minimizes tailing when changing gas stream composition.

-

High sensitivity thermal conductivity detector (TCD) is 2x as sensitive as alternatives so you can measure smaller samples volumes, detect secondary reactions, and have greater confidence in your results.

-

Temperature-controlled corrosion-resistant detector is compatible with corrosive gases and inherently protected from gas leaks that can destroy alternative designs, providing high reliability and long operational life.

-

Exclusive AutoTrap provides superior moisture removal for TPR experiments with a system that is effortless to use and saves hours per day.

-

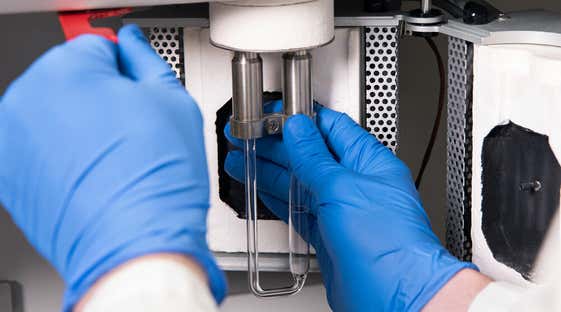

KwikConnect retention system makes sample tube mounting quick, easy, and safe with no threaded connections and half as many separate pieces as traditional designs.

-

Dynamic clamshell furnace provides temperature control up to 1200°C and controlled heating rates from 0.1°C/min to 100°C/min with the lowest available temperature overshoot.

-

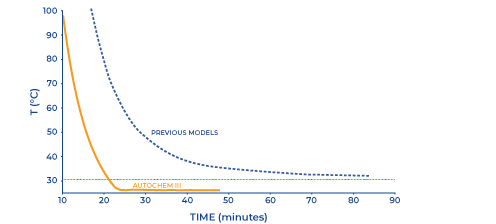

Integrated AutoCool cools the furnace and sample quicker than forced air alone without the use of cryogenic liquids, saving an average of 30 minutes per experiment.

-

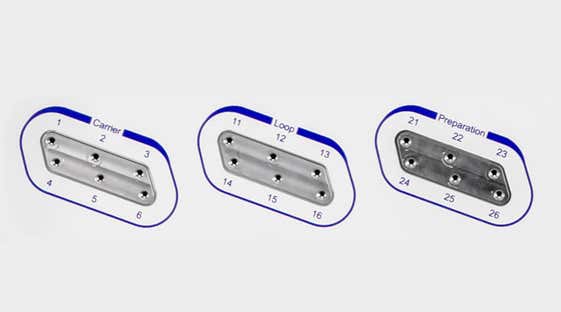

18 total gas inlets - six each for preparation, carrier, and loop gases permit sequential experiments of different types and saves time between experiments.

Applications

-

- Net zero technologies

-

The development of efficient and effective catalysts is necessary to the continued development of CO2 mitigation and the hydrogen economy that will enable a sustainable energy future. The AutoChem III is a useful tool to optimize adsorption and dissociation of H2/O2 on electrolysis electrodes, show whether desorption occurs near reaction conditions, quantify acid or base sites to optimize reactivity and selectivity, and more.

- Fuel cells

-

Platinum-based catalysts including Pt/C, PtRu/C, and PtRuIr/C are often characterized by temperature-programmed reduction to determine the number of oxide phases and pulse chemisorption to calculate: metal surface area, metal dispersion and average crystallite size.

- Partial oxidation

-

Manganese, cobalt, bismuth, iron, copper, and silver catalysts used for the gas-phase oxidation of ammonia, methane, ethylene, and propylene are characterized using temperature-programmed oxidation and desorption, heat of desorption & dissociation of oxygen.

- Catalytic cracking

-

Acid catalysts such as zeolites are used to convert large hydrocarbons to gasoline and diesel fuel. The characterization of these materials includes ammonia chemisorption and temperature-programmed desorption.

- Catalytic reforming

-

Catalysts containing platinum, rhenium, tin, etc. on silica, alumina, or silica alumina are used for the production of hydrogen, aromatics, and olefins.

- Isomerization

-

Catalysts such as small-pore zeolites (mordenite and ZSM-5) containing noble metals (typically platinum) are used to convert linear paraffins to branched paraffins.

- Hydrocracking: Hydrodesulfurization and Hydrodenitrogenation

-

Hydrocracking catalysts typically composed of metal sulfides (nickel, tungsten, cobalt, and molybdenum) are used for processing feeds containing polycyclic aromatics that are not suitable for typical catalytic cracking processes.

- Water gas shift reaction

-

The water-gas shift reaction is an important element in the hydrogen lifecycle and the push toward net-zero technologies. The combination of catalysts, often copper-zinc-alumina and iron-chromia, are characterized by TPR and pulse chemisorption to maximize activity.

System configurations

Mass spec provides a direct probe for the identity and quantity of specific reaction products. This is especially valuable when investigating an unknown reaction, or a reaction that creates multiple products. The single quadrupole mass spec with heated transfer line provides detection of mass fragments up to 200 amu and data collection that is integrated with the operation of the AutoChem III. The AutoChem III also includes a general mass spec communication port for coordination with a lab’s existing mass spec.

Prepare samples for analysis or perform measurements in the presence of pulsed or continuous vapor streams such as water, alcohol, pyridine, aromatic organics, and more.

Begin experiments at temperatures as low as -100 °C with controlled liquid-nitrogen-based cooling.

For reaction chemistries that require particularly aggressive gas compositions, a special version of the AutoChem III is available with enhanced corrosion resistance. Wetted materials are constructed from highly resistant Hastelloy, highly stable perfluoro elastomers, and inert-coated stainless steel to provide the greatest stability under the harshest working conditions