Overview

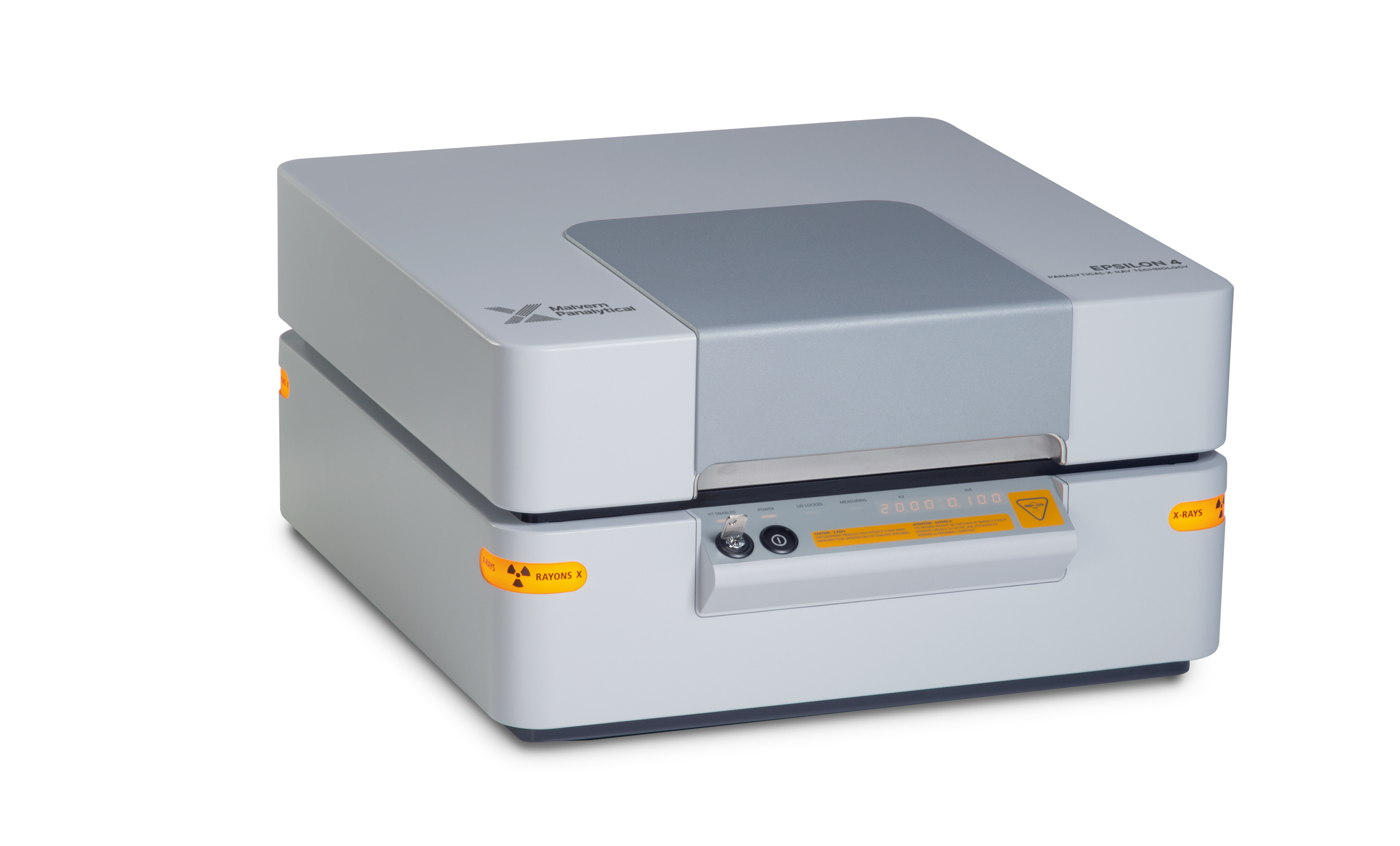

Your customers demand superior consistency of your polymer performance and consumer safety regardless of production location. The Epsilon 4, an energy dispersive X-ray fluorescence (EDXRF) benchtop spectrometer, provides elemental analysis with superior repeatability and accuracy, satisfying your customer’s consistency demands.

Ease-to-use measurement procedures and limited utility requirements enables reproducible analysis close to production lines and across multiple production sites. The Epsilon 4 delivers reliable results for months without recalibration. Guaranteeing your product quality was never easier.

Features

-

The power of benchtop XRF: Combining the latest excitation and detection technologies and smart design, the analytical performance of Epsilon 4 approaches that of more powerful and floor-standing spectrometers. Selective excitation and careful matching of the X-ray tube output to the capabilities of the detection system underlie the system’s outstanding performance.

-

Low running costs: Epsilon 4 does not require the use of expensive acids, gasses and fume hoods, like in ICP and AAS. The only requirement is mains electricity and in some cases the use of helium to boost the sensitivity for light elements in the sample. Also, the individual components in XRF spectrometers are not exposed to friction or heat and therefore last for many years.

-

Fast and sensitive: Fast measurements are achieved by using the latest silicon drift detector technology that produces significantly higher intensities. Unique detector electronics enable a linear count rate capacity to over 1,500,000 cps (at 50% dead time) and a count rate independent resolution typically better than 135 eV for better separation of analytical lines in the spectrum. This allows the Epsilon 4 spectrometer to run at full power and therefore realizes a much higher sample throughput compared to traditional EDXRF benchtop instruments.

-

Non-destructive analysis: Measurements with Epsilon 4 are carried out directly on loose powders or end products, with little to no sample preparation. Since XRF is a non-destructive technique, the sample can also be measured subsequently by other analytical techniques, if required.

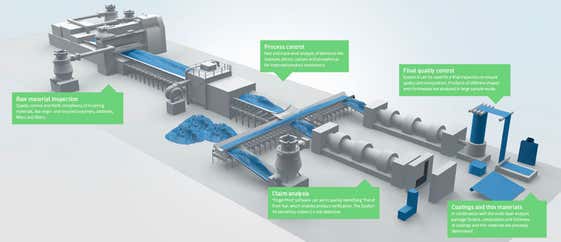

Focus on product quality and consistency

The Epsilon 4 offers its value directly to producers of polymers, plastics and paints. Enable full traceability by fast and direct analysis throughout and close to production processes. Validate the quality of incoming raw materials and analyse the presence of additives, catalyst residues and toxic elements in final products.

Malvern Panalytical unique calibration solutions ADPOL, TOXEL and RoHS supports its users to realize consumer safety and a consistent and high-end product quality and performance.

Unique polymer application solutions

Installation qualification and operation qualification procedures are available for Epsilon 4.

These procedures are instrument verification and validation procedures required by companies to meet good laboratory practice (GLP), good manufacturing practice (GMP) and FDA 21 CFR Part 11 regulations.

Key applications

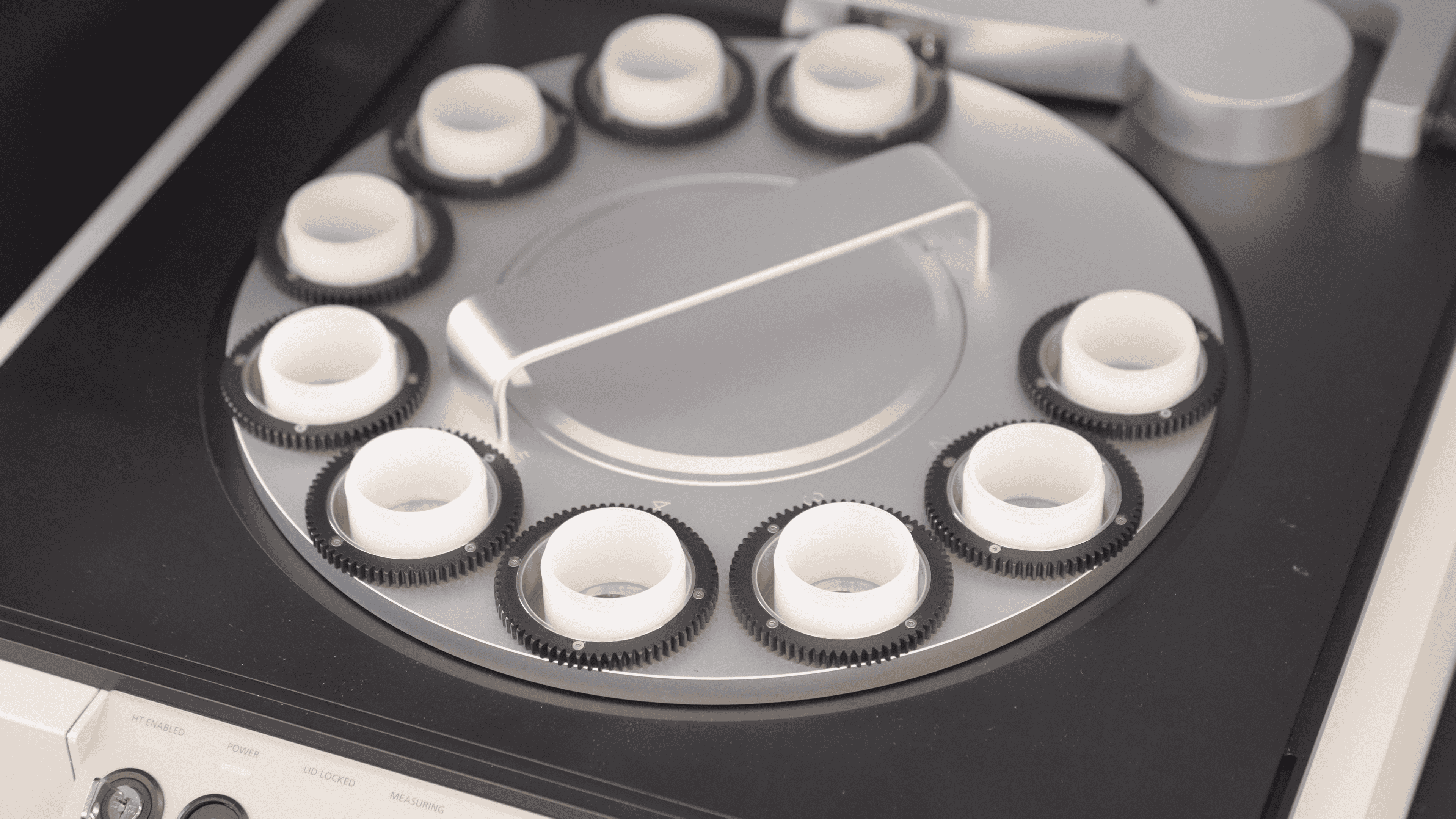

Epsilon 4 spectrometers can handle a large variety of sample types, weighing from a few milligrams to larger bulk samples. Samples can be measured as:

- Solids

- Pressed powders

- Loose powders

- Liquids

- Fused beads

- Slurries

- Granules

- Filters

- Films and coatings

Great tool. Quick analysis, easy-to-use repeatable. Very helpful and competent assistance.

Omar Scaccabarozzi — Analyst