KnowItAll® ID Expert software platform from Wiley

Wiley’s KnowItAll® ID Expert software platform works seamlessly with Malvern Panalytical’s Morphologi software to provide rapid identification of your Raman spectra.

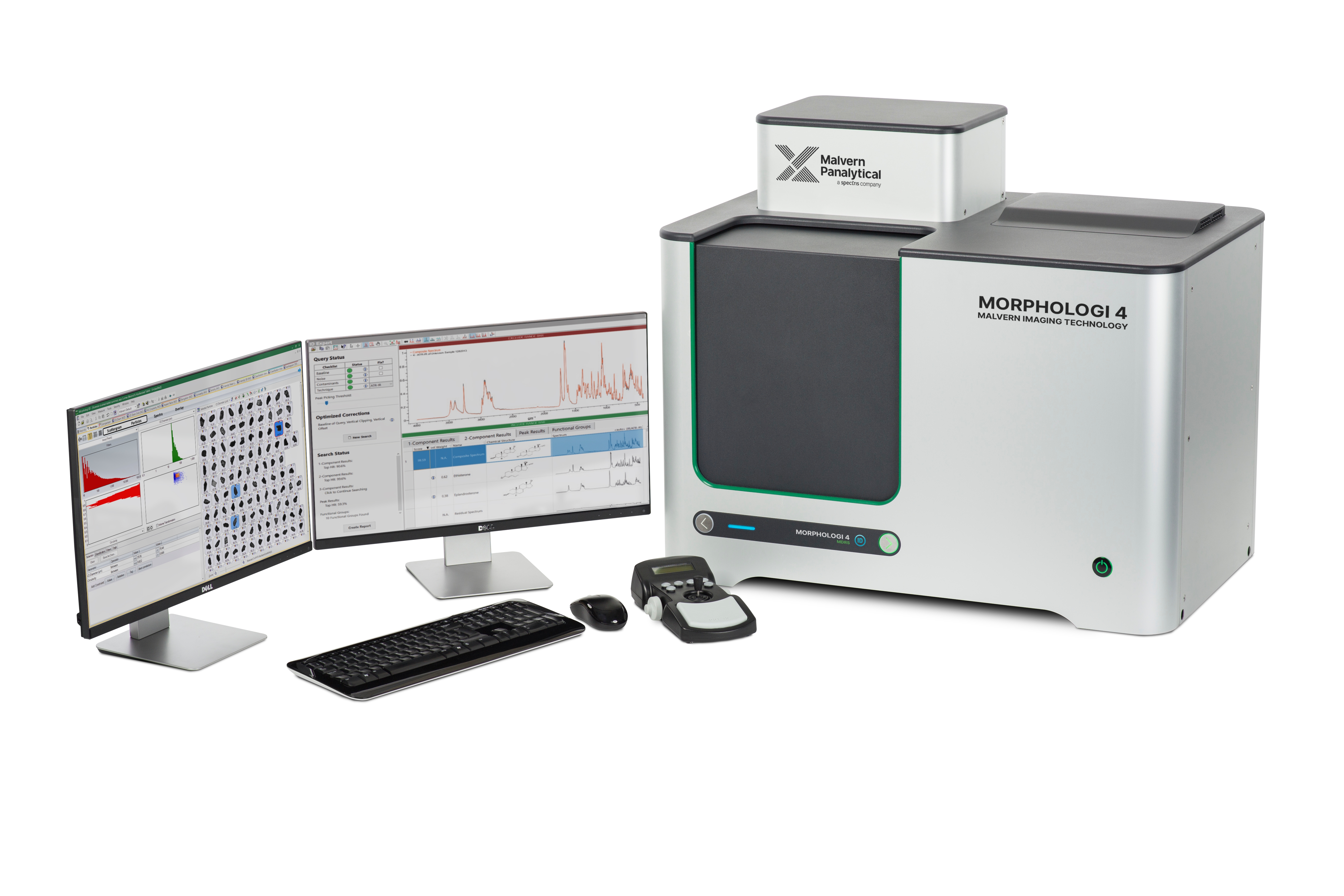

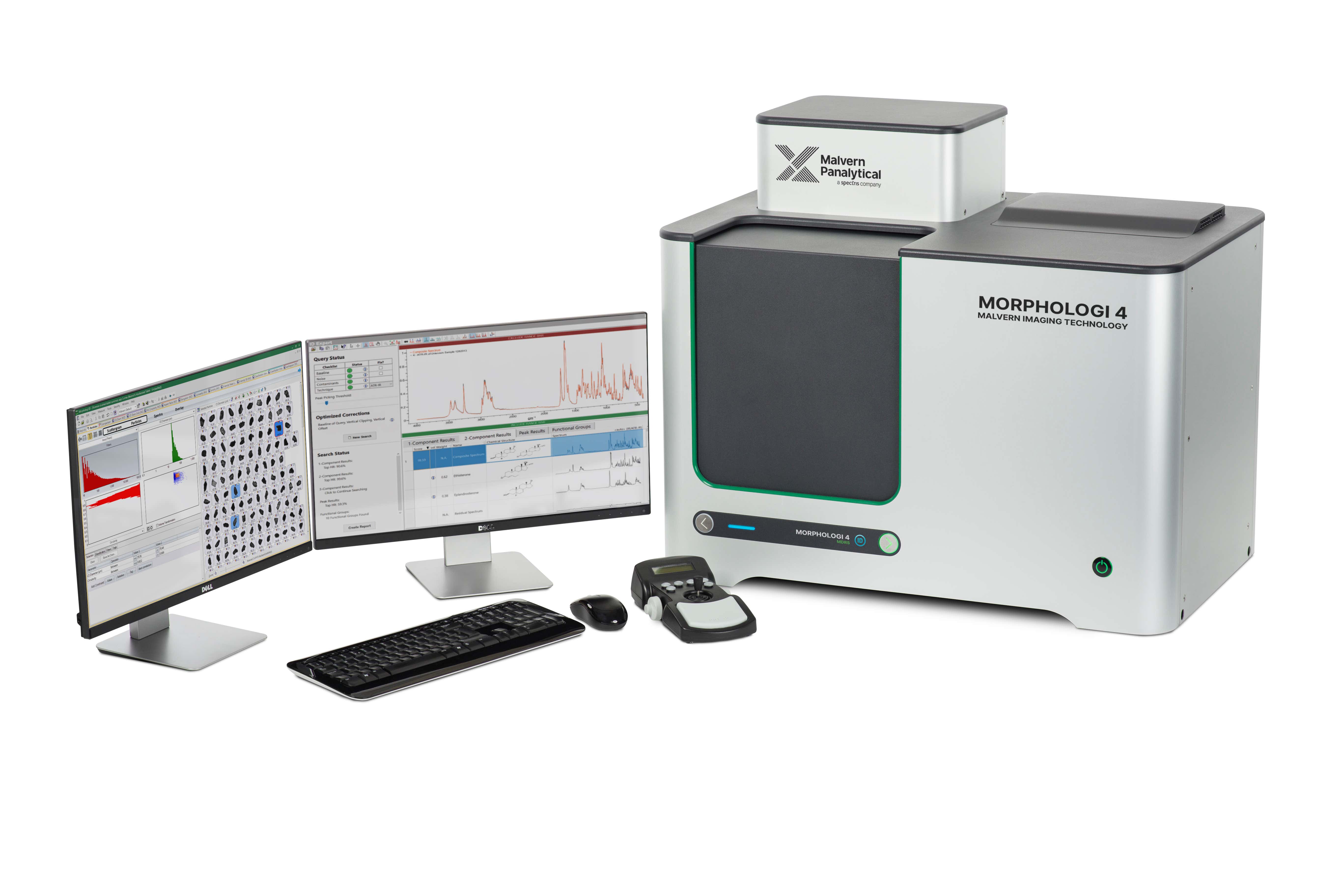

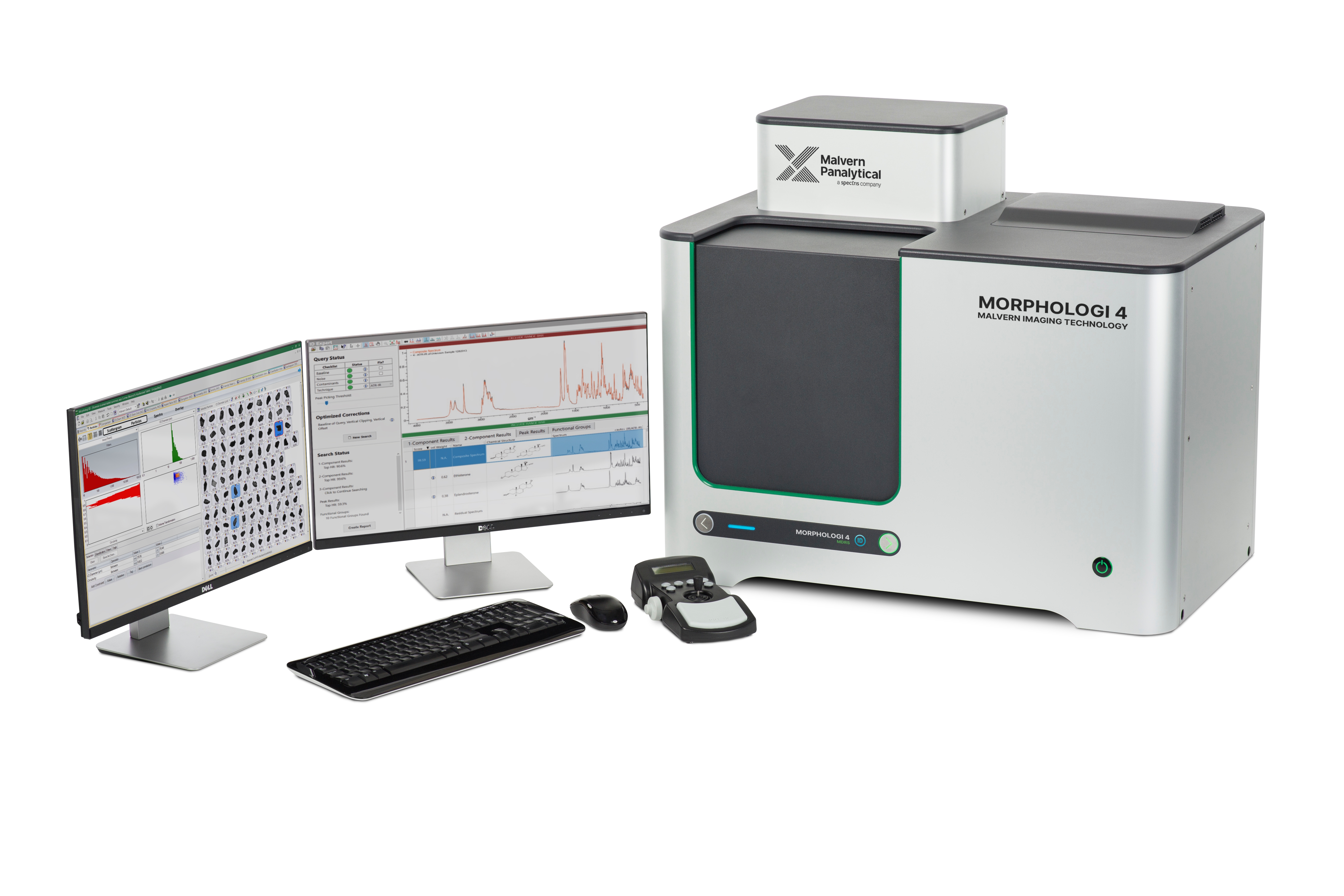

Morphologi 4-ID delivers detailed component-specific morphological descriptions of particulate blends through Morphologically-Directed Raman Spectroscopy (MDRS). This combines automated particle imaging with Raman spectroscopy in a single, integrated platform, providing the power to unlock complex particle characterization problems. Morphologi 4-ID software works seamlessly with Wiley’s KnowItAll® Raman Identification Pro software platform to provide rapid identification of your Raman spectra.

Looking for more information?

To request a quote, more information or download a brochure select an option below.

The Morphologi 4-ID offers an exclusive capability, combining all the benefits of automated static imaging delivered by the Morphologi 4 with chemical identification of individual particles by Raman spectroscopy in a single measurement.

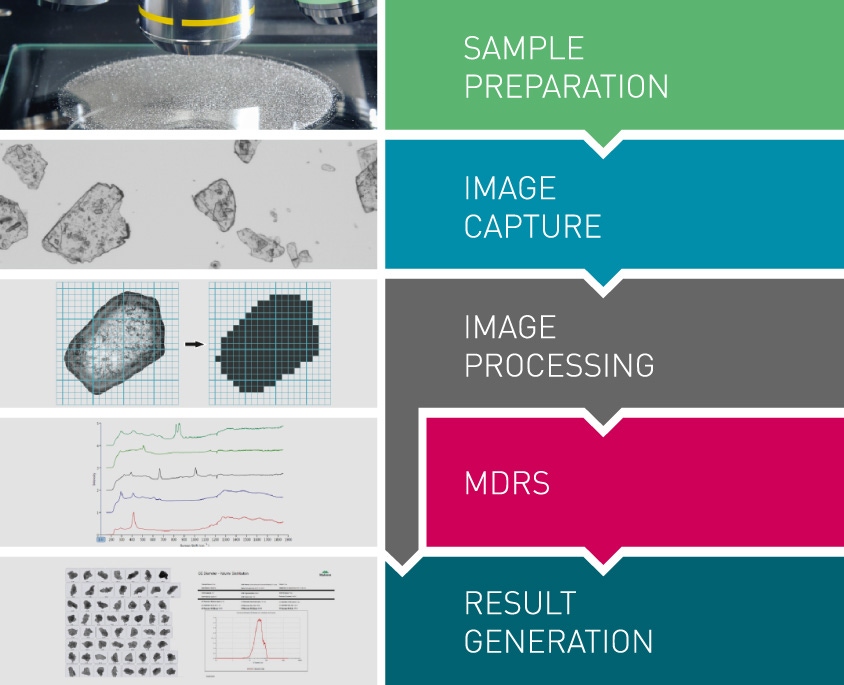

The Morphologi 4-ID measurement procedure can be split into five sections:

Sample preparation

Spatial separation of individual particles and agglomerates is critical to robust results. The integrated dry powder disperser makes preparing dry powder samples easy and reproducible. The applied dispersion energy can be precisely controlled, enabling the measurement process to be optimized for a range of material types. Accessories that fit directly in to the Morphologi 4-ID’s automated stage are available for preparing suspended or filtered samples.

Image capture

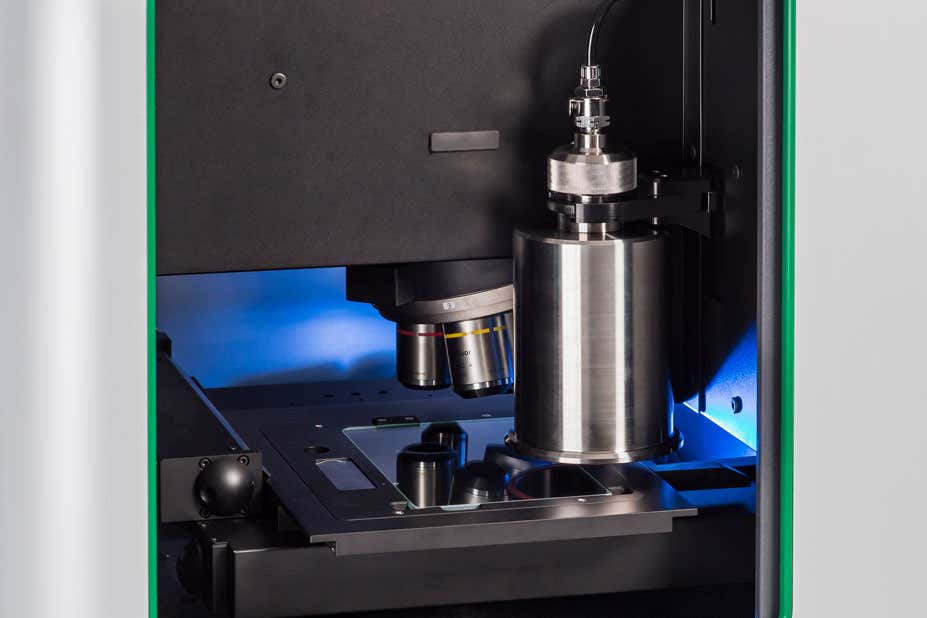

The instrument captures images of individual particles by scanning the sample underneath the microscope optics. The Morphologi 4-ID can illuminate the sample from below or above, whilst accurately controlling the light levels.

Image processing

Use of either the automated ‘Sharp Edge’ segmentation analysis or the manually-controlled thresholding enables the detection of particles and the calculation of a range of morphological parameters for each.

MDRS

Components and particles of interest are targeted for Raman analysis. Particles can be selectively targeted based on their morphology, or particles representative of the whole sample can be targeted objectively by the Morphologi software.

Result generation

Advanced graphing and data classification options in the software ensure that extracting the relevant data from the measurement is straightforward, via an intuitive visual interface. Correlation scores to a reference library are calculated for each Raman spectrum acquired, enabling particles to be classified based on their chemistry. The morphological data associated with the particles in each chemical class is used to generate size and shape distributions, delivering component-specific morphological information. Individually-stored grayscale images for each particle are linked to their Raman spectra and provide qualitative verification of the quantitative results.

| Technology | Static automated imaging |

|---|---|

| Particle size | 0.5 μm – 1300 μm (upper limit may be extended for some applications*) |

| Particle properties measured | Size, shape, transparency, count, location |

| Particle size parameters |

Circle equivalent (CE) diameter, length, width, perimeter, area, maximum distance, sphere equivalent (SE) volume, fiber total length, fiber width

|

| Particle shape parameters |

Aspect ratio, circularity, convexity, elongation, high sensitivity (HS) circularity, solidity, fiber elongation, fiber straightness

|

| Particle transparency parameters | Intensity mean, intensity standard deviation |

| Integrated Sample Dispersion Unit |

For fully automated dispersion and measurement of dry powders. Manual or SOP control of

dispersion pressure, injection time and settling time

|

| Illumination | White light LED: brightfield, diascopic and episcopic; darkfield, episcopic |

| Detector | 18 MP; 4912 x 3684 pixel color CMOS array; pixel size 1.25 μm x 1.25 μm |

| Optical system | Nikon CFI 60 brightfield / darkfield system |

| Lens (and particle size range) |

2.5x: 8.5 µm – 1300 µm (nominal)

5x: 4.5 µm – 520 µm (nominal)

10x: 2.5 µm – 260 µm (nominal)

20x: 1.5 µm – 130 µm (nominal)

50x: 0.5 µm – 50 µm (nominal)

|

| Size range | 1 μm - 1300 μm* |

|---|---|

| Spectral performance |

150 cm-1 to 2800 cm-1

|

| Wavelength | 785 nm |

| Power output from spectrometer | < 100 mW |

| Power output at sample | > 45 mW at max power |

| Laser spot size | 2 µm at 50x magnification |

| Laser safety | Class 1 |

| Chemical identification method | Raman spectral correlation |

| Dimensions (W, D, H) |

810 mm (W) x 520 mm (D) x 685 mm (H)

with carry handles: 1100mm (W) x 520mm (D) x 685mm (H)

|

|---|---|

| Weight | 80 kg (88 kg including carry handles) |

| Power | 100-240 V ac 50/60 Hz (<100W load) |

| Notes | * Sample and substrate dependent |

|---|

Appropriate dispersion of the individual particles and agglomerates within a sample leads to robust and reliable results. Good spatial separation and representative sampling of the particles is required. To achieve this, a number of dispersion options are available with the Morphologi 4-ID.

Easy, reproducible, automated sample dispersion

Morphologi 4-ID comes with an integrated dry powder dispersion unit. It enables simple, reproducible preparation of dry powder samples. A precise amount of sample is dispersed automatically using a unique compressed air dispersion mechanism controlled from within the software, for reproducible dispersions every time.

Optional accessories – for analysis of particles in suspension

A range of instrument accessories supports preparation of samples on microscope slides, in wet suspensions or on filters, extending the capability of the Morphologi 4-ID beyond the characterization of dry sample dispersions. Each accessory fits directly into the automated stage area and is easily selectable in the Morphologi software.

Wiley’s KnowItAll® ID Expert software platform works seamlessly with Malvern Panalytical’s Morphologi software to provide rapid identification of your Raman spectra.

‘Sandwiching’ a few μL of a suspension of smaller particles between a microscope slide and a cover slip is a traditional method of sample preparation for microscopy. Samples are presented in this form to the Morphologi G3-ID using either the 2-slide or 4-slide holder. Slides suitable for chemical identification applications are available.

The thin-path wet cell is designed for both morphological and chemical characterization of up to 100 μL of sample. It is ideal for applications such as the identification of subvisible particles in therapeutics (described by guidance in USP <787> and USP <788>), especially when a traditional membrane filtering approach may risk changing particles of interest, such as protein aggregates.

Fused silica filters are designed to enable the analysis of filtered samples containing low-contrast particles, such as protein aggregates or contaminant particles. The fused silica filters are housed in a support for ease of handling, and are presented to the Morphologi in the fused silica holder, which can hold up to 2 filters.

Protect your investment and ensure optimized performance at all times with Malvern Panalytical's service plans.

When you purchase a Malvern Panalytical product we understand that this is just the first stage of a working relationship that will last for the lifetime of the instrument. Depending on your needs, Malvern Panalytical will provide the support for your business.

For laboratories where maximizing instrument up-time is critical to its daily performance. Our highest level of response and the 'all inclusive' price plan takes care of those unexpected repair bills should the unfortunate occur.

Enhance your laboratory productivity by maintaining instrument efficiency. Still receive that priority response, combined with specialist technical and software support, we'll keep your instrument performance on track to deliver.

For laboratories looking to optimize instrument performance, regular preventative maintenance is essential.

| Platinum Plan | Gold Plan | Bronze Visit | |

|---|---|---|---|

| Annual PM/PV Test | yes | yes | no |

| Telephone / Email Support | yes | yes | no |

| Priority Response | yes | yes | no |

| Emergency Breakdown visits* | yes | yes | no |

| Parts Included | yes | no | no |

| Technical & Software Support | yes | yes | yes |

| IQ/OQ (Pharma)*** | yes | yes | yes |

*including labour & travel costs ***available at an additional cost

The Morphologi 4-ID provides value in a wide range of applications, some of which are described below:

Building materials

Cement is a complex mixture of minerals and additives, the component-specific particle properties of which affect final product performance. The capability of the Morphologi 4-ID system to analyze and characterize specific particle populations within a cement blend enables different batches or products to be compared, aiding product development and solving production problems. It brings new insight to conventional cement manufacture and supports industry objectives to incorporate environmentally sustainable replacement materials, such as fly ash and blast furnace slag.

Energy storage/batteries

Morphologi ID systems can support product development and ensure final product quality by providing information on the chemical composition and structure of electrode materials, enabling their correlation with battery performance.

Forensics

Forensic analysis requires physical and chemical information to interpret evidence. Raman spectroscopy is routinely used in forensic investigations and combining this with automated imaging provides enhanced insight into the physical and chemical properties of unknown and complex mixtures, allowing differentiation between morphologically similar substances. The particle size , shape and chemical information delivered by Morphologi systems enables the detection of counterfeit pharmaceuticals or illicit drugs, the identification of contaminant particles in powders, and the examination of soils and other residues from crime scenes to support the investigative process.

Mining and minerals

The morphology of geological deposits helps trace the extent of natural disasters and predict the impact of future environmental events. Particle properties also determine the effectiveness of abrasive minerals for use in cutting and polishing tools. Morphologi automatically generates the statistically relevant, component-specific particle data required to meet these challenges.

Pharmaceutical development

Morphologi ID systems are used by companies across various stages of the pharmaceutical development cycle. The rapid, chemical component-specific morphological information helps to optimize and control both API and excipient particle size and shape during development, and throughout formulation and processing. For generics, this information can be used to simplify and solve deformulation challenges and help establish in vitro bioequivalence. It can also be used to detect anomalies, contaminants and pinpoint process deviations during manufacturing.

OINDP (Orally Inhaled and Nasal Drug Products)

The precise control of particle size and shape is critical in OINDP development and manufacturing, directly impacting drug delivery and efficacy. Morphologi 4-ID provides detailed morphological information of each chemical component, enabling the characterization of active pharmaceutical ingredients (APIs) in formulated blends. This system facilitates the development and optimization of formulations by assessing the impact of blends, processing conditions and devices on the particle size and shape distributions of the API. It supports in-vitro bioequivalence of generic Nasal Spray products through comparison of the API particle properties with the reference product, after actuation. Moreover, it allows for the identification and quantification of foreign particulates, crucial for maintaining product safety and regulatory compliance.

All the benefits of automated static imaging, with added particle chemical identification by Raman spectroscopy in a single measurement. Powerful, automated and easy to use particle characterization.